Have you ever wondered how metal pieces become perfectly shaped? One secret lies in using a metal lathe. This fantastic machine allows us to shape metal into many useful items. But did you know that having a strong and sturdy stand for your lathe is just as important?

Imagine trying to carve a block of wood. If your workbench wobbles, your carving might turn out messy. It’s the same with a metal lathe. A solid metal lathe stand holds everything in place. This stability makes sure your work is neat and safe.

Many people don’t realize the role a good stand plays. A reliable lathe metal shaping stand can improve your projects. It can even help beginners feel more confident. So, in this article, we will explore how to choose the best stand and why it matters. Let’s dive into the world of metal shaping together!

Lathe Metal Shaping: Essential Guide To Metal Lathe Stand

Lathe Metal Shaping and Metal Lathe Stand

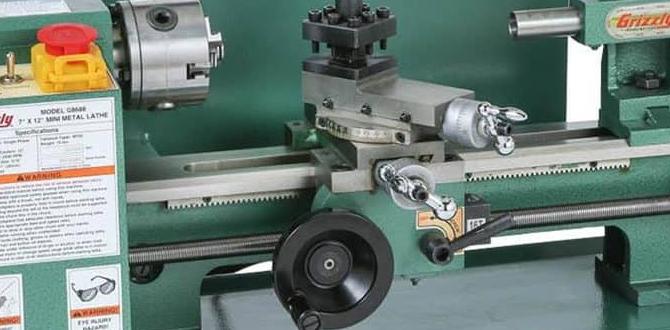

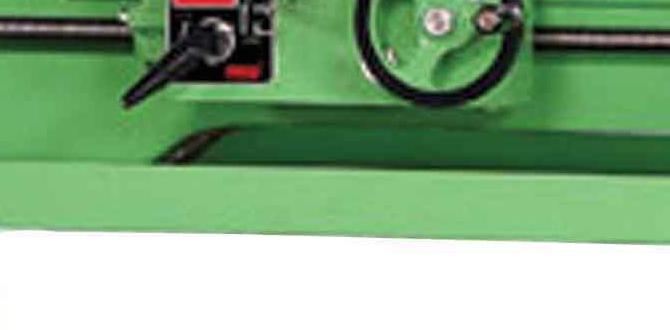

A metal lathe is a powerful tool that helps shape metal into various forms. Do you ever wonder how a simple block of metal turns into a precise part? The metal lathe stand provides stability during this process. A sturdy stand keeps the lathe steady, ensuring accurate cuts. Choosing the right stand can improve your work quality. Did you know that even a small adjustment in height can make a big difference? Discover how these tools change raw metal into masterpiece creations.

Understanding the Importance of a Metal Lathe Stand

Discuss the role of a sturdy stand in lathe operation.. Explain how a proper stand affects precision and stability..

A metal lathe stand plays a key role in lathe operations. A strong and stable stand helps you achieve better precision while shaping metal. If the stand is wobbly, it can cause mistakes. Imagine trying to draw a straight line on a shaking table! Here are some important points:

- Stability: A sturdy stand keeps the lathe steady.

- Precision: Better stability means more accurate work.

- Safety: A good stand reduces the risk of accidents.

In short, having the right metal lathe stand is essential for any project.

Why is a stable lathe stand important?

A stable lathe stand ensures that your work is safe, accurate, and efficient.

Essential Features of an Effective Metal Lathe Stand

Outline key attributes such as height, weight capacity, and material.. Explore customization options for specific lathe models..

An ideal metal lathe stand needs a few key features to help you work smoothly. First, consider the height. It should match your comfort level, so you don’t feel like a pretzel while you work! Next, think about weight capacity. A sturdy stand can support a hefty lathe without wobbling like a jelly on a plate. Of course, the material matters too; strong metals will outlast any flimsy stand. Customization options are also great! Choose the right design for your specific lathe model and you’ll be golden. Here’s a quick table to summarize:

| Feature | Importance |

|---|---|

| Height | For comfort and easy use |

| Weight Capacity | Supports heavy lathes securely |

| Material | Durable for long-lasting use |

| Customization | Matches your lathe model |

With these features, you can set up a mighty workstation. Remember, a solid stand is like a trusty sidekick in a superhero movie—it’ll help you tackle any project!

Materials to Consider for Your Lathe Stand

Compare common materials: wood, metal, and industrialgrade composites.. Assess the pros and cons of each material type..

Choosing a material for your lathe stand is important. Each option has its own pros and cons. Here’s a quick comparison:

- Wood: Wood is sturdy and easy to work with. It looks nice but can warp over time.

- Metal: Metal is strong and holds up well. It can be heavy and might need welding.

- Industrial-grade composites: These materials are durable and lightweight. However, they can be more expensive.

Think about your needs and workspace. Which material fits best for your lathe metal shaping metal lathe stand? It’s wise to pick one that matches your projects for best results.

What is the best material for a lathe stand?

The best material for a lathe stand is metal for strength and durability.

Step-by-Step Guide to Building a Custom Metal Lathe Stand

Provide detailed instructions including required tools and materials.. Include tips for ensuring level and sturdy construction..

Building a custom stand for your metal lathe is like making a comfy couch for a robot—everyone needs a solid spot to show off their skills! First, gather your tools: a tape measure, a saw, and a wrench. You’ll also need materials like plywood and sturdy metal legs.

Start by measuring the height for comfort and cutting the wood. Assemble your legs securely; stable means no wobbling like a jelly! Use a level to check your work—it should stand tall and proud, not crooked! Here’s a quick table to guide you:

| Tool/Material | Purpose |

|---|---|

| Tape Measure | For accurate measurements |

| Saw | To cut wood |

| Wrench | For tightening screws |

| Plywood | Main structure of the stand |

| Metal Legs | To support the lathe |

Following these steps will keep your lathe steady, making your metal shaping adventures way more fun!

Common Mistakes to Avoid When Setting Up Your Lathe Stand

Identify prevalent errors impacting lathe performance.. Explain how to troubleshoot and correct these mistakes..

Setting up a lathe stand can be tricky. A common error is not leveling it properly. If the lathe wobbles, it’s like trying to ride a unicycle on a rollercoaster! Another mistake is ignoring the weight limit. Make sure your stand can handle the machine’s heft to avoid accidents. If you spot any wobbles, try adjusting the feet for balance. Always double-check your setup, or you might just be making a metal spaghetti instead of precise metal shapes!

| Error | Solution |

|---|---|

| Unlevel stand | Adjust feet for balance |

| Overloaded weight | Check weight limits |

Maintaining Your Metal Lathe Stand for Longevity

Discuss routine maintenance tips and best practices.. Highlight potential problems and preventative measures..

Keeping your metal lathe stand in great shape is like giving your favorite toy a check-up! First, check for rust. A little rust can make the stand grumpy. Wiping it down with a cloth keeps it shiny and happy. Tighten loose bolts too. They are like sleepy friends that need a nudge to wake up. Also, clean the surface where you work; dust can be a sneaky troublemaker. Here’s a table of quick maintenance tips:

| Maintenance Task | Frequency |

|---|---|

| Check for rust | Every month |

| Tighten bolts | Every week |

| Clean work surface | After each use |

By following these steps, your metal lathe stand will have the strength of a superhero! Remember, a little care goes a long way to avoid big problems!

Accessories to Enhance Your Metal Lathe Stand

Suggest addons such as drawers, tool holders, and vibration dampeners.. Describe how each accessory can improve workflow and efficiency..

Adding a few accessories can turn your metal lathe stand into a super handy workspace. First up, drawers help keep your tools organized and close by. No more searching like a lost pirate for that wrench! Then we have tool holders that keep everything in place, so you can grab what you need in a flash, saving precious time. Lastly, vibration dampeners reduce shakes, letting you work smoothly without the annoying buzz that makes your coffee dance. Who knew metal shaping could also be fun?

| Accessory | Benefit |

|---|---|

| Drawers | Keep tools organized and easily accessible. |

| Tool Holders | Quick access to tools, improving work speed. |

| Vibration Dampeners | Reduce shakes for a smoother working experience. |

Real User Experiences: Reviews of Different Lathe Stands

Present testimonials and insights from users of various stands.. Analyze performance comparisons and user satisfaction ratings..

Many users have shared their thoughts on different lathe stands. Most of them appreciate stability and ease of use. One user said, “My lathe stand makes shaping metal feel like a breeze!” Others point out that some stands wobble too much, turning projects into a comedy show instead of a workshop. User satisfaction varies, with some stands getting top ratings while others barely scrape by. Here’s a quick look at what users think:

| Lathe Stand | User Rating | Comments |

|---|---|---|

| Heavy-Duty Model | ⭐️⭐️⭐️⭐️⭐️ | Sturdy and reliable! |

| Lightweight Stand | ⭐️⭐️ | Wobbles like a dance party! |

| Adjustable Stand | ⭐️⭐️⭐️⭐️ | Great features, but tricky to set up. |

So, whether you want a stable rock or a dancing partner, reviews can guide your choice!

Conclusion

In summary, a metal lathe stand is important for shaping metal accurately. It keeps your lathe stable while you work. When choosing a stand, consider its height and strength to match your lathe. We encourage you to explore different designs and setups to find what works best for you. Happy shaping, and keep learning about metalworking!

FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Metal Shaping And Metal Lathe Stands:

Sure! A lathe is a machine that helps shape metal. It spins the metal while a tool cuts it. You can make things like parts for machines or tools. A metal lathe stand holds the lathe up so it doesn’t move. Having a sturdy stand is very important for safety.

Sure! Please provide the question you want me to answer.

What Are The Key Factors To Consider When Selecting A Stand For A Metal Lathe?

When choosing a stand for a metal lathe, you should think about stability first. A strong, sturdy stand helps keep the lathe safe while you work. Next, check if the height is comfortable for you. It’s also good to see if the stand has space for storing tools and supplies. Lastly, make sure it fits the size of your lathe perfectly.

How Does The Stability Of A Lathe Stand Impact The Precision Of Metal Shaping Operations?

A stable lathe stand helps keep the lathe steady. When it doesn’t wobble, the cuts you make are smoother and more accurate. A strong stand also means the machine won’t shift while you work. This way, you get better shapes and sizes for your metal pieces. Overall, stability helps create good-quality work.

What Materials Are Commonly Used To Construct Metal Lathe Stands, And What Are Their Advantages?

Metal lathe stands are often made from steel, wood, or aluminum. Steel is strong and can hold heavy machines. Wood is lighter and easier to shape, but it might not be as sturdy. Aluminum is light and rust-resistant, making it great for easy movement. Each material has its own good points!

Can A Diy Metal Lathe Stand Be Effectively Created, And What Essential Design Features Should It Include?

Yes, you can make a DIY metal lathe stand! First, it should be strong and stable to hold the lathe. Adding adjustable legs helps you level it on uneven floors. We can use wood or metal for the frame. Also, remember to have space for tools and easy access to the lathe.

How Do Different Lathe Stand Heights Affect Ergonomics And User Comfort During Machining Tasks?

Different lathe stand heights can change how comfortable you feel while working. If the lathe is too low, you might bend down a lot, which can hurt your back. If it’s too high, you might have to reach up, making your arms tired. Finding the right height helps you stay relaxed and work better. It makes the job easier and safer for you.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Metal Shaping And Metal Lathe Stands:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine that helps shape metal. It spins the metal while a tool cuts it. You can make things like parts for machines or tools. A metal lathe stand holds the lathe up so it doesn’t move. Having a sturdy stand is very important for safety.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Factors To Consider When Selecting A Stand For A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a stand for a metal lathe, you should think about stability first. A strong, sturdy stand helps keep the lathe safe while you work. Next, check if the height is comfortable for you. It’s also good to see if the stand has space for storing tools and supplies. Lastly, make sure it fits the size of your lathe perfectly.”}},{“@type”: “Question”,”name”: “How Does The Stability Of A Lathe Stand Impact The Precision Of Metal Shaping Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A stable lathe stand helps keep the lathe steady. When it doesn’t wobble, the cuts you make are smoother and more accurate. A strong stand also means the machine won’t shift while you work. This way, you get better shapes and sizes for your metal pieces. Overall, stability helps create good-quality work.”}},{“@type”: “Question”,”name”: “What Materials Are Commonly Used To Construct Metal Lathe Stands, And What Are Their Advantages?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathe stands are often made from steel, wood, or aluminum. Steel is strong and can hold heavy machines. Wood is lighter and easier to shape, but it might not be as sturdy. Aluminum is light and rust-resistant, making it great for easy movement. Each material has its own good points!”}},{“@type”: “Question”,”name”: “Can A Diy Metal Lathe Stand Be Effectively Created, And What Essential Design Features Should It Include?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, you can make a DIY metal lathe stand! First, it should be strong and stable to hold the lathe. Adding adjustable legs helps you level it on uneven floors. We can use wood or metal for the frame. Also, remember to have space for tools and easy access to the lathe.”}},{“@type”: “Question”,”name”: “How Do Different Lathe Stand Heights Affect Ergonomics And User Comfort During Machining Tasks?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different lathe stand heights can change how comfortable you feel while working. If the lathe is too low, you might bend down a lot, which can hurt your back. If it’s too high, you might have to reach up, making your arms tired. Finding the right height helps you stay relaxed and work better. It makes the job easier and safer for you.”}}]}