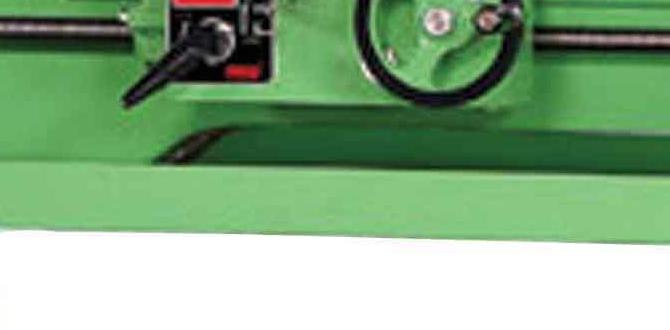

Have you ever wondered how a lathe works? These machines spin metal to create amazing shapes and designs. But what happens when the lathe motor fails? This can be very frustrating for anyone who loves working with metal. In many cases, a lathe motor replacement is all you need to get back to your project.

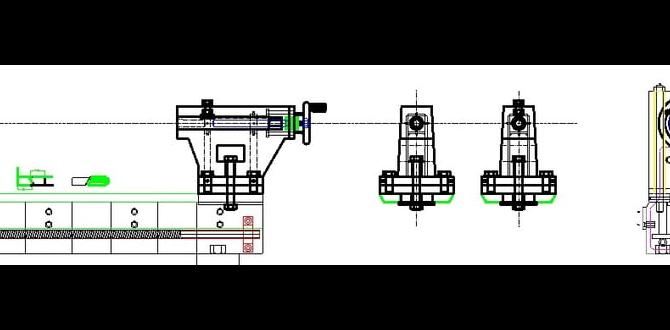

With a new motor, your metal lathe can run smoothly again. But how do you choose the right one? And what about using CAD design to help you? CAD design can simplify the process, making it easier to visualize your new setup.

Imagine being able to create stunning projects without your lathe being out of commission. The good news is that replacing a lathe motor is not just a challenge; it’s also an opportunity. You can upgrade your equipment and improve your skills.

In this article, we’ll explore the steps for lathe motor replacement. You’ll also see how CAD design can help guide your work. Let’s dive in and discover how to keep your metal lathe in top shape!

Lathe Motor Replacement: Metal Lathe Cad Design Solutions

Lathe Motor Replacement and Metal Lathe CAD Design

Replacing a lathe motor can seem tricky, but it’s important for smooth operation. Metal lathe CAD design can help you visualize parts and connect them better. Imagine designing a lathe with ease on your computer! This not only saves time but also enhances precision. Did you know that modern CAD software allows you to test your designs virtually? Choosing the right motor boosts your machine’s performance. Proper planning leads to amazing results in your projects!

Understanding Lathe Motors

Types of lathe motors: AC vs. DC. Importance of selecting the right motor for efficiency.

Lathe motors come in two types: AC and DC. AC motors are like the steady tortoises; they run smoothly but can be slower to start. Meanwhile, DC motors are the speedy hares that get going quickly but might need more care. Picking the right motor is crucial for efficiency, making your cuts precise and saving you energy (and maybe your sanity!). A good choice means less downtime and more time enjoying your freshly made projects!

| Type | Pros | Cons |

|---|---|---|

| AC Motor | Steady operation, lasts long | Slower start, less powerful torque |

| DC Motor | Quick start, high torque | Requires maintenance, may overheat |

Identifying the Need for Motor Replacement

Signs of motor failure in metal lathes. Common issues that necessitate replacement.

Look for signs of trouble with your lathe motor. A slow or unresponsive motor can mean it’s failing. You might hear unusual sounds or see smoke, which is never good. These issues can lead to serious problems. Here are some common signs:

- Vibrations or shaking during operation.

- Frequent overheating.

- Inconsistent speeds while running.

- Burnt or damaged wiring.

- Failing to start or stop correctly.

If you notice these signs, it may be time for a motor replacement. Addressing these issues early can help you avoid bigger problems later.

How do I know if my lathe motor needs replacement?

Watch out for weird noises, overheating, or slow speeds. These could mean your lathe motor is not working properly. Early signs can save you time and money!

Steps to Prepare for Motor Replacement

Tools and equipment required for replacement. Safety precautions to consider before starting.

Before changing your lathe motor, gather the right tools. You’ll need a wrench, screwdriver, and safety glasses. Make sure you have a work surface that is clean and well-lit. Safety is important! Always wear gloves and keep loose clothing away from moving parts. Here’s a quick list:

- Wrench

- Screwdriver

- Safety glasses

- Gloves

Check everything first. This will help you work safely and effectively.

Why is safety important during motor replacement?

Safety prevents injuries and accidents. When working with machines, it’s easy to get hurt. So, take your time and double-check everything.

Detailed Lathe Motor Replacement Process

Stepbystep instructions for removing the old motor. Installing the new motor: best practices for alignment.

Replacing a lathe motor is straightforward. Follow these steps for a smooth process. First, unplug the lathe and make sure it’s cool.

- Remove the motor cover carefully.

- Unscrew the old motor from its mount.

- Detach any wires connected to the old motor.

Now, install the new motor. Align it properly before securing it. This helps keep everything running smoothly.

- Connect the wires based on the new motor’s diagram.

- Double-check the alignment with the lathe’s drive system.

- Tighten the screws carefully to make sure it’s secure.

This simple method ensures your lathe works well again.

How do I know if I need to replace my lathe motor?

If your lathe motor makes strange noises or runs irregularly, it may be time for a replacement. Check for physical damage, too. Signs of wear can indicate a need for a new motor.

Troubleshooting Common Replacement Issues

Electrical connection problems and solutions. Mechanical alignment challenges and how to fix them.

When replacing your lathe motor, you might face some sneak-attack issues. First, let’s talk about electrical connection problems. If your machine won’t start, check the wires. They can be as tangled as a ball of yarn! Ensure everything is snug and connected properly. Next up, we have mechanical alignment challenges. If your motor sounds like a rock band trying to play in sync, the alignment may be off. Adjust the positions until everything runs smoothly. Remember, patience is key—like waiting for your pizza delivery!

| Issue | Solution |

|---|---|

| Electrical connection problems | Check and tighten all wires |

| Mechanical alignment issues | Adjust motor positions for smooth operation |

Testing and Calibration After Replacement

Importance of proper testing postinstallation. Calibration techniques for optimal lathe performance.

After replacing the lathe motor, testing and calibration are crucial. Proper testing ensures everything works smoothly. This step helps avoid problems later. Calibration is also important for the lathe’s best performance. It fine-tunes how the machine operates. Regular calibration keeps the lathe precise and efficient.

- Check motor performance with simple tests.

- Use gauges to measure accuracy.

- Adjust settings to match desired outcomes.

Why is testing and calibration important?

Testing and calibration help ensure your lathe performs its best. They help catch mistakes before they cause big issues.

Maintenance Tips for Longevity of Your New Lathe Motor

Regular upkeep routines to extend motor life. Warning signs that indicate the need for maintenance.

To keep your new lathe motor happy, regular upkeep is key. Think of it like a pet; it needs care! Check for dust and debris every week. Also, feel for unusual vibrations—this could mean something is off. Don’t ignore funny noises either; they can be the motor’s way of asking for help. A clean motor runs smoother and lasts longer. Here’s a quick table to help you remember:

| Maintenance Task | Frequency |

|---|---|

| Clean motor and area | Weekly |

| Check for unusual sounds | Every use |

| Inspect belts and wiring | Monthly |

So, treat your lathe motor well! After all, a happy motor means smooth sailing (or cutting). Remember, neglecting signs is like ignoring a sneeze—it can lead to big problems!

Conclusion

In conclusion, replacing a lathe motor is essential for keeping your metal lathe running well. CAD design helps you plan and visualize your projects. By learning these skills, you can enhance your machining abilities. We encourage you to explore tutorials or guides on motor replacement and CAD design. Start your journey today and improve your crafting experience!

FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Motor Replacement And Cad Design For Metal Lathes:

Sure! When you want to replace a lathe motor, first turn off the power. Then, take out the old motor carefully. After that, put the new motor in its place and connect the wires. You can use CAD, which stands for Computer-Aided Design, to plan your lathe parts on a computer. This helps you see everything before you build it.

Sure! Please go ahead and ask your question, and I’ll help you with a short answer.

What Are The Key Specifications To Consider When Selecting A Replacement Motor For A Metal Lathe?

When choosing a new motor for a metal lathe, you should think about a few important things. First, check the power, which is how strong the motor is—it should match what you need. Next, consider the speed, which tells you how fast the motor can turn. You should also look at the size and weight to make sure it fits on your lathe. Finally, make sure it’s the right type, like AC (Alternating Current) or DC (Direct Current), depending on your needs.

How Can Cad Software Be Utilized To Design A Custom Mounting Bracket For A New Lathe Motor?

You can use CAD software, which stands for Computer-Aided Design, to make a custom mounting bracket. First, you sketch the bracket’s shape on the screen. Then, you can add measurements to make sure it fits the new lathe motor perfectly. Once you’re happy with the design, you can save it and print it out. This helps you create a strong and exact bracket for your lathe motor!

What Are The Common Challenges Faced When Retrofitting A New Motor To An Existing Metal Lathe Design?

When you try to add a new motor to an old metal lathe, you might face a few problems. First, the new motor might not fit with the old parts. Second, you may need special tools to connect everything safely. Also, the power needs might be different, which can cause issues. Finally, finding the right size and strength for the motor can be tricky.

How Can Simulation Tools Within Cad Software Help Optimize The Performance Of A Lathe After Motor Replacement?

Simulation tools in CAD (Computer-Aided Design) software can help us test new ideas before we make changes. After replacing a motor on a lathe, we can use these tools to see how it works. They allow us to check if the lathe will run smoothly and safely. We can also find the best settings to make it work faster or better. This way, we can fix problems before they happen!

What Factors Should Be Taken Into Account For The Electrical Compatibility Of A New Motor With Existing Lathe Controls?

When we want to use a new motor on a lathe, we should check a few things. First, we need to match the motor’s voltage to the lathe’s controls. Then, we should see if the motor’s power (how strong it is) is okay for the lathe. Also, we must consider if the control wiring fits the new motor. Finally, checking the speed settings is important too, so everything works well together.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Motor Replacement And Cad Design For Metal Lathes:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! When you want to replace a lathe motor, first turn off the power. Then, take out the old motor carefully. After that, put the new motor in its place and connect the wires. You can use CAD, which stands for Computer-Aided Design, to plan your lathe parts on a computer. This helps you see everything before you build it.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please go ahead and ask your question, and I’ll help you with a short answer.”}},{“@type”: “Question”,”name”: “What Are The Key Specifications To Consider When Selecting A Replacement Motor For A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a new motor for a metal lathe, you should think about a few important things. First, check the power, which is how strong the motor is—it should match what you need. Next, consider the speed, which tells you how fast the motor can turn. You should also look at the size and weight to make sure it fits on your lathe. Finally, make sure it’s the right type, like AC (Alternating Current) or DC (Direct Current), depending on your needs.”}},{“@type”: “Question”,”name”: “How Can Cad Software Be Utilized To Design A Custom Mounting Bracket For A New Lathe Motor?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can use CAD software, which stands for Computer-Aided Design, to make a custom mounting bracket. First, you sketch the bracket’s shape on the screen. Then, you can add measurements to make sure it fits the new lathe motor perfectly. Once you’re happy with the design, you can save it and print it out. This helps you create a strong and exact bracket for your lathe motor!”}},{“@type”: “Question”,”name”: “What Are The Common Challenges Faced When Retrofitting A New Motor To An Existing Metal Lathe Design?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you try to add a new motor to an old metal lathe, you might face a few problems. First, the new motor might not fit with the old parts. Second, you may need special tools to connect everything safely. Also, the power needs might be different, which can cause issues. Finally, finding the right size and strength for the motor can be tricky.”}},{“@type”: “Question”,”name”: “How Can Simulation Tools Within Cad Software Help Optimize The Performance Of A Lathe After Motor Replacement?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Simulation tools in CAD (Computer-Aided Design) software can help us test new ideas before we make changes. After replacing a motor on a lathe, we can use these tools to see how it works. They allow us to check if the lathe will run smoothly and safely. We can also find the best settings to make it work faster or better. This way, we can fix problems before they happen!”}},{“@type”: “Question”,”name”: “What Factors Should Be Taken Into Account For The Electrical Compatibility Of A New Motor With Existing Lathe Controls?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we want to use a new motor on a lathe, we should check a few things. First, we need to match the motor’s voltage to the lathe’s controls. Then, we should see if the motor’s power (how strong it is) is okay for the lathe. Also, we must consider if the control wiring fits the new motor. Finally, checking the speed settings is important too, so everything works well together.”}}]}