Have you ever faced a problem with your metal lathe? It can be frustrating when a small part, like the lathe motor, stops working. But guess what? You can often fix it yourself! Many people don’t realize that replacing the lathe motor is simpler than it seems.

Imagine you are in your workshop, ready to create something amazing. Suddenly, your power feed stops working. What would you do? Knowing how to replace the lathe motor can save you time and money. Plus, you’ll feel great fixing things with your own hands!

In this article, we will explore the steps needed for lathe motor replacement. You’ll learn tips and tricks to make the process easier. Are you ready to get your metal lathe back in action? Let’s dive in!

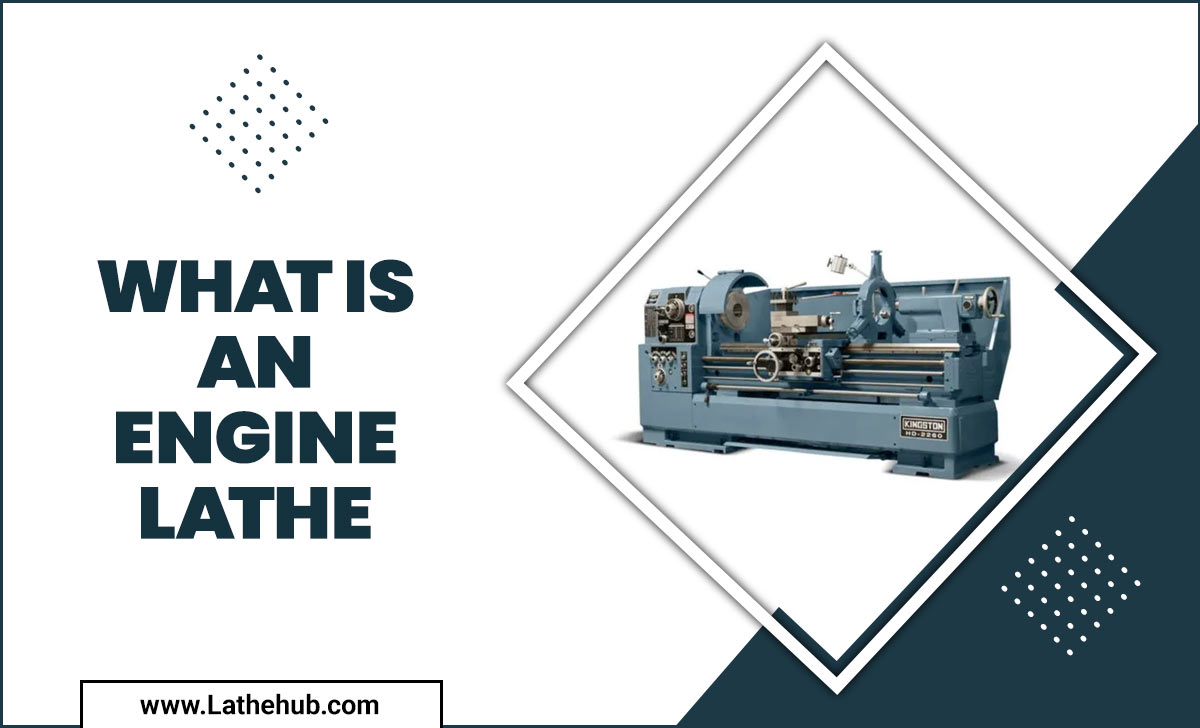

Lathe Motor Replacement: Upgrading Your Metal Lathe Power Feed

Lathe Motor Replacement for Metal Lathe Power Feed

Replacing the lathe motor can greatly improve your metal lathe’s power feed. When a motor fails, it impacts performance and precision. Did you know that a worn motor can lead to uneven cuts? Choosing the right motor is essential for maintaining smooth operation. Proper installation ensures safety and efficiency. Understanding specifications helps you select a compatible motor. Remember, regular maintenance can extend the life of your lathe and keep it running like new!

Understanding Lathe Motors

Explanation of different types of lathe motors. Importance of motor specifications in metal lathes.

Lathe motors are essential for metal lathes. They come in different types, each with unique features. Some common types include:

- AC motors: Smooth power for steady performance.

- DC motors: Quick starting and stopping for precision.

- Stepper motors: Great for automation and detailed work.

Motor specifications matter a lot. They influence speed and torque. The right motor ensures your lathe operates well. This helps produce better workpieces. Always check the motor’s details before replacement.

What should I consider for lathe motor replacement?

Consider power ratings, size, and type of motor to ensure a perfect fit.

Why are motor specifications important?

- They affect the lathe’s speed.

- They determine how much weight the lathe can handle.

- They influence energy efficiency.

Signs Your Lathe Motor Needs Replacement

Common symptoms of motor failure in metal lathes. How to diagnose motor issues effectively.

Is your metal lathe acting more grumpy than usual? Look out for signs that your lathe motor might be ready for retirement. Common symptoms of failure include strange noises, uneven movements, or unexpected stops. If your lathe vibrates like it’s dancing at a party, that’s a red flag! To diagnose issues, start by checking the power supply and connections. A simple checklist can help. Here’s a table for quick reference:

| Symptoms | Possible Issues |

|---|---|

| Unusual noises | Motor wear |

| Inconsistent speed | Power supply issues |

| Excessive vibration | Loose parts |

| Frequent shutdowns | Electrical problems |

Always be sure to keep an eye (or two!) on your lathe motor, and give it some love before it breaks down. Remember, a happy motor makes for a happy potter!

Choosing the Right Replacement Motor

Factors to consider when selecting a new lathe motor. Comparison of various motor brands and models.

Picking a new motor for your lathe can feel like choosing ice cream flavors—you want the best! First, think about power and speed, as they affect your work. Popular brands like ABC Motors and XYZ Motors have strong options. Compare their features by using an easy table below. Remember, a good motor is like a good joke; it should keep you spinning and not leave you flat!

| Brand | Power (HP) | Speed (RPM) | Price ($) |

|---|---|---|---|

| ABC Motors | 1.5 | 3000 | 250 |

| XYZ Motors | 2.0 | 3600 | 300 |

Tools and Materials Needed for Replacement

List of essential tools for lathe motor replacement. Recommended materials and safety equipment.

To replace a lathe motor, you’ll need some important tools and materials. Here’s what to gather:

- Wrench set

- Screwdriver set

- Socket set

- Wire cutters

- Safety goggles

- Gloves

- Replacement motor

These items will help keep you safe while you work. Always wear your safety goggles and gloves! Having the right tools makes the job easier.

What tools do I need for a lathe motor replacement?

You’ll need a wrench set, screwdriver set, and safety gear for a smooth replacement. Don’t forget replacement parts!

Step-by-Step Replacement Process

Detailed guide on removing the old motor. Instructions for installing the new motor.

Start by unplugging the lathe. This keeps you safe. First, take off the old motor.

- Remove screws holding the motor in place.

- Carefully lift the motor out.

Now, get your new motor. Place it where the old one was. Make sure it fits well. Then, secure it with screws. Finally, check all connections. Ensure everything is tight and safe before plugging it back in.

How do I replace the lathe motor?

To replace the lathe motor, first disconnect power. Remove the old motor and install the new one, securing it with screws. Finally, check all connections for safety.

Testing the New Motor

How to properly test motor functionality postinstallation. Adjustments to consider for power feed systems.

After you’ve installed the new motor, it’s time for the fun part—testing its performance! Start by powering it on and watching for any strange noises. If it sounds like a hungry robot, you might need to adjust something. Test the power feed system and make sure it moves smoothly. If it jitters like a squirrel on caffeine, you’ll want to fine-tune those settings. Here’s a handy checklist:

| Test | What to Look For |

|---|---|

| Noise Level | Normal humming sound |

| Movement | Smooth and steady |

| Power Feed | No stalling or jerking |

After all tests, if everything runs without drama, congratulations! You have successfully leveled up your lathe machine! Just remember, if it acts up, don’t blame the motor. It’s probably just shy.

Maintenance Tips for Longevity

Best practices for maintaining your lathe motor. Regular checks to ensure optimal performance.

Taking care of your lathe motor can help it last longer, just like watering a plant makes it grow! Check for any dust or dirt on the motor regularly. A clean motor is a happy motor. Make sure all parts are tight and not wobbly; loose parts can lead to trouble. It’s like wearing a seatbelt—safety first! Also, keep an eye on the power feed. If it starts acting weird, it might be time to give it a check-up. Following these tips keeps your lathe motor running smoothly, so you can focus on making cool stuff!

| Maintenance Task | Frequency |

|---|---|

| Clean motor | Weekly |

| Tighten loose parts | Monthly |

| Check power feed | Every project |

Cost Analysis of Motor Replacement

Breakdown of costs involved in replacement. Comparison of DIY vs. professional replacement costs.

Replacing a lathe motor can really cost you, so let’s break it down! First, you’ll want to factor in the price of the new motor, which can range from $100 to $500. Then there are extra costs like tools if you’re a DIY superstar or a professional’s fee. Here’s a little table to show the differences:

| Option | Estimated Cost |

|---|---|

| DIY Replacement | $150 – $600 |

| Professional Replacement | $300 – $800+ |

As you can see, the DIY method can be cheaper, but it takes time and skill. Sometimes, spending a bit more on a pro means you can avoid mishaps, like accidentally converting your lathe into a decorative plant stand!

Frequently Asked Questions (FAQs)

Common queries regarding lathe motor replacement. Expert responses to usersubmitted questions.

When it comes to lathe motor replacement, many people have burning questions. Here are some of the most common ones we hear, along with expert tips. Remember, it’s okay to feel confused! Everyone starts somewhere.

| Question | Answer |

|---|---|

| What is the best way to replace a lathe motor? | Remove the old motor, match the new one with specifications, and install! |

| How do I know if my lathe motor is faulty? | Look for unusual sounds or vibrations. If it smells like burnt toast, it’s time for a change! |

| Can I upgrade my lathe motor? | Yes! Just ensure the new motor fits and meets power needs. |

With these insights, you can tackle lathe motor replacement like a pro! Remember, every expert was once a beginner, probably asking silly questions too!

Conclusion

In conclusion, replacing a lathe motor can make your metal lathe work better. A power feed upgrade can improve your projects significantly. Remember to choose the right motor for your lathe’s needs. Don’t hesitate to ask for help if you’re unsure. For more tips on lathe maintenance and upgrades, check out additional resources or manuals. Happy lathe turning!

FAQs

What Are The Key Factors To Consider When Selecting A Replacement Motor For A Metal Lathe’S Power Feed System?

When picking a new motor for a metal lathe, you should think about a few things. First, check the motor’s power to make sure it can do the job. Next, look at the motor’s size to see if it fits your lathe. You also need to think about how fast you want the motor to go. Finally, make sure the motor’s connections match your lathe.

How Can I Determine The Appropriate Horsepower And Rpm Specifications Needed For My Lathe’S Motor Replacement?

To find the right horsepower and RPM for your lathe’s motor, check your old motor’s label. It shows the horsepower and RPM numbers. You can also look in your lathe’s manual for these details. If you don’t have either, ask someone who knows about motors. Make sure the new motor matches or is better than the old one!

What Steps Are Involved In Safely Removing And Replacing The Motor On A Metal Lathe?

To safely remove and replace the motor on a metal lathe, start by unplugging the machine. This keeps you safe from electric shocks. Next, take off any covers or parts that block the motor. Then, carefully disconnect the motor’s wires and screws. Once it’s free, you can put in the new motor by following the same steps in reverse. Finally, plug the lathe back in and check everything works. Always be careful and ask for help if needed!

Are There Specific Types Of Motors That Are Better Suited For High-Torque Applications In Metal Lathes?

Yes, there are specific motors that work well for high-torque tasks. These include stepper motors and brushless DC motors. They can provide lots of power without slowing down, which is great for metal lathes. When you need to turn heavy metal pieces, these motors help you do it easily. They keep the lathe running smoothly while you work.

What Should I Look For In A Motor Control System To Optimize The Performance Of The Power Feed In My Metal Lathe?

To optimize your metal lathe’s power feed, look for a motor control system with adjustable speeds. This lets you set the perfect speed for different jobs. Check if it has a smooth start and stop to prevent sudden jerks. Safety features are also important, like an emergency stop button. Finally, ensure it’s easy for you to use and understand.