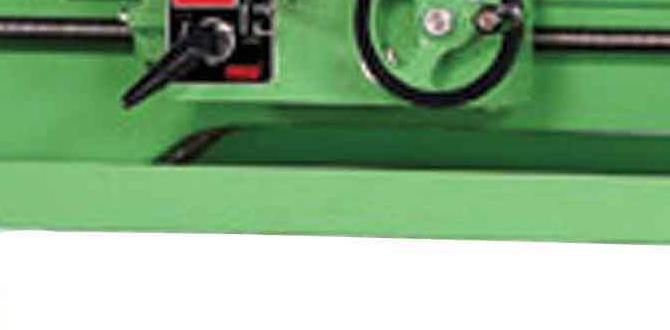

Have you ever watched a metal lathe work? It’s like magic as it shapes metal with precision. But what happens when the lathe motor stops working? It can feel frustrating. You might wonder how to fix it.

In this article, we will explore the importance of lathe motor replacement. A well-functioning motor makes a huge difference in your projects. Imagine being able to switch between tools quickly with a quick change tool post. It saves time and lets you create amazing things!

Did you know that replacing your lathe motor can be a fun DIY project? Many people find satisfaction in fixing things themselves. With the right tips and tools, you can become a lathe pro. So, let’s get started on this journey together!

Lathe Motor Replacement For Metal Lathe Quick Change Tool Post

Understanding Lathe Motor Replacement and Quick Change Tool Posts

Replacing a lathe motor can breathe new life into your metal lathe. An efficient motor powers your tools, making projects smoother. Have you ever struggled with tool changes? A quick change tool post solves that problem. It allows for fast and easy swaps during work. This improvement helps save time and boosts productivity. Knowing how to replace your lathe motor and install a tool post can enhance your machining experience. Discover the transformation in your workshop!

Signs Your Lathe Motor Needs Replacement

Common symptoms of a failing lathe motor. Testing your lathe motor for performance issues.

Your lathe motor can show signs when it’s not working right. Look for these common problems:

- Unusual noises like grinding or whining.

- Inconsistent speed while running.

- Burning smell during operation.

- Frequent stopping or jerking movements.

To test your motor for issues, check if it starts easily. Listen for strange sounds and feel for vibrations. If you see any of these signs, it might be time for a replacement.

How do I know if my lathe motor is failing?

Watch for strange noises or smells. If the motor stops suddenly or runs unevenly, these are signs it might need replacing. Testing the speed and feel can also help catch problems early.

Selecting the Right Replacement Motor

Factors to consider when choosing a replacement motor. Comparing different brands and models.

Choosing the right replacement motor is vital for your metal lathe. It affects performance, efficiency, and safety. Here are key factors to think about:

- Power: Ensure the motor matches your lathe’s needs.

- Size: Check the dimensions for a proper fit.

- Brand: Research reputations and reviews.

- Cost: Compare prices across different models.

Look at various brands to find the best motor for you. Some well-known brands might offer different warranties, which can be helpful.

What should I consider when choosing a motor?

Consider power needs, size, brand reputation, and cost. Knowing these can help you make the best choice for your metal lathe.

Guide to Replacing Your Lathe Motor

Stepbystep process for safe motor replacement. Essential tools and safety precautions for motor replacement.

Replacing a lathe motor can seem tricky, but it’s easier than finding your lost sock! First, gather your essential tools: wrenches, screwdrivers, and safety glasses. Safety comes first—always unplug the lathe before starting. Next, follow these quick steps:

| Step | Action |

|---|---|

| 1 | Remove the old motor carefully. |

| 2 | Disconnect all wires. |

| 3 | Install the new motor and connect the wires. |

| 4 | Double-check everything. |

| 5 | Plug it back in and test! |

Remember, safety gear is your best friend. Protect those peepers and fingers while you work!

Adjusting for the Quick Change Tool Post

How lathe motor power affects quick change tool post performance. Tips for optimizing tool post settings after motor replacement.

After replacing the lathe motor, adjust the quick change tool post for the best results. The motor’s power affects how well the tool post works. A stronger motor means faster and smoother cutting. To optimize settings, make sure the tool post is secure. Here are some tips:

- Check that the tool post is level with the bed of the lathe.

- Tighten all screws and clamps properly.

- Adjust the tool height for precision cuts.

These changes help improve performance and accuracy. With the right adjustments, your projects will shine!

How does motor power affect tool post performance?

The power of the motor helps the quick change tool post move easily and accurately. More power means the tool can cut better and faster.

Tips for tuning your tool post:

- Ensure proper alignment to prevent vibrations.

- Use the correct tool holder to match the task.

Maintenance Tips for Longevity

Routine maintenance practices for motors on metal lathes. How to extend the lifespan of your lathe motor.

Keeping your lathe motor healthy is like giving your car a good oil change—it just makes things run smoother! Regularly check the motor for dust and debris; a clean motor can last longer. Lubricate the moving parts to avoid pesky squeaks. Tighten loose screws, or your lathe might sound like a hungry raccoon! And remember, never overload it. A happy motor means a happy lathe!

| Maintenance Task | Frequency |

|---|---|

| Check for Dust | Monthly |

| Lubricate Parts | Every 3 Months |

| Tighten Screws | As Needed |

| Check Load | Continuous |

By following these simple tips, you can ensure your lathe motor runs smoothly, giving you precise results for years to come. Remember, an ounce of prevention is worth a pound of cure!

Common Mistakes to Avoid

Frequent errors when replacing lathe motors. How to troubleshoot issues postreplacement.

Replacing a lathe motor can be tricky. Many people make common mistakes. Here are some errors to avoid:

- Not checking the power supply first.

- Ignoring the motor’s size and compatibility.

- Forgetting to connect wires correctly.

- Neglecting to test the motor after installation.

If things don’t work after the change, check these:

- Ensure the power is on.

- Look for loose connections.

- Verify the right motor is installed.

Taking care with these steps can save you time and effort!

What are some signs that I need to replace my lathe motor?

Common signs include strange noises, vibrations, or the motor not starting. Checking these can prevent big problems.

How can I troubleshoot after replacing the lathe motor?

If the motor doesn’t run, check connections, power supply, and motor compatibility. Fixing these issues quickly can get you back to work.

Finding Professional Help

When to consider hiring a professional for motor replacement. Resources for finding qualified technicians in your area.

Sometimes, fixing a lathe motor can be tricky. If you feel like you’re in a tangle, it might be time to call in the pros. A seasoned technician can save you time and headaches, like finding a map in a maze. Start your search at local hardware stores or online directories for qualified experts nearby.

| Resource | Description |

|---|---|

| Local Hardware Stores | They often know reliable technicians. |

| Online Directories | Websites that list skilled workers in your area. |

| Community Boards | Check for recommendations from neighbors. |

Just remember, hiring a pro can help your lathe run smoothly, and you won’t have to fumble around with instructions that look more like hieroglyphics!

Conclusion

In summary, replacing the lathe motor can improve your metal lathe’s performance. A quick change tool post saves time and boosts your efficiency. By understanding these tools, you can enhance your projects significantly. Don’t stop here—explore more about lathe maintenance and tool upgrades to keep your work exciting and effective. Happy turning!

FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Motor Replacement And Quick Change Tool Posts For Metal Lathes:

Sure! When you replace a lathe motor, it helps the machine work better. You can turn metal smoothly. A quick change tool post lets you switch tools easily. This saves time when you’re working on your projects. Using these parts makes metalworking more fun and efficient!

Sure! Please provide the question you would like me to answer.

What Are The Key Considerations When Selecting A Replacement Motor For A Metal Lathe?

When choosing a new motor for a metal lathe, we need to think about a few important things. First, check the power the motor needs to work well. We also need to match the size of the motor to the lathe. Think about how fast you want the lathe to spin. Finally, consider how much money you want to spend on the new motor.

How Do You Properly Install A Quick Change Tool Post On A Metal Lathe?

To install a quick change tool post on a metal lathe, start by removing the old tool holder. Next, clean the area where the new tool post will sit. Then, place the quick change tool post onto the lathe’s saddle and line it up. You can tighten the screws to hold it in place. Finally, check that it’s secure before adding tools for use.

What Are The Benefits Of Upgrading To A Quick Change Tool Post Compared To Using A Standard Tool Holder?

Upgrading to a quick change tool post makes changing tools much faster. With a quick change tool post, you don’t need to use a lot of tools and screws. You can switch tools in seconds. This saves time and helps you finish your projects quicker. It also makes your work more fun because you spend less time setting up!

How Can You Troubleshoot Common Issues That Arise During Lathe Motor Replacement?

To fix common problems when changing a lathe motor, start by checking the power supply. Make sure it’s plugged in and working. Next, look at all the wires for damage. If they are loose, tighten them. Lastly, if the motor doesn’t run, check the motor switch for issues. Always be careful and turn off the power when you work on it!

What Are The Best Practices For Maintaining A Lathe Motor And Tool Post To Ensure Optimal Performance?

To keep your lathe motor and tool post working great, start by cleaning them often. Dust and dirt can cause problems, so use a soft cloth or brush. Make sure to check for any loose parts and tighten them if needed. You should also lubricate moving parts with oil to help them run smoothly. Lastly, always follow the manufacturer’s instructions to keep everything safe and working well.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Motor Replacement And Quick Change Tool Posts For Metal Lathes:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! When you replace a lathe motor, it helps the machine work better. You can turn metal smoothly. A quick change tool post lets you switch tools easily. This saves time when you’re working on your projects. Using these parts makes metalworking more fun and efficient!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Considerations When Selecting A Replacement Motor For A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a new motor for a metal lathe, we need to think about a few important things. First, check the power the motor needs to work well. We also need to match the size of the motor to the lathe. Think about how fast you want the lathe to spin. Finally, consider how much money you want to spend on the new motor.”}},{“@type”: “Question”,”name”: “How Do You Properly Install A Quick Change Tool Post On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To install a quick change tool post on a metal lathe, start by removing the old tool holder. Next, clean the area where the new tool post will sit. Then, place the quick change tool post onto the lathe’s saddle and line it up. You can tighten the screws to hold it in place. Finally, check that it’s secure before adding tools for use.”}},{“@type”: “Question”,”name”: “What Are The Benefits Of Upgrading To A Quick Change Tool Post Compared To Using A Standard Tool Holder?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Upgrading to a quick change tool post makes changing tools much faster. With a quick change tool post, you don’t need to use a lot of tools and screws. You can switch tools in seconds. This saves time and helps you finish your projects quicker. It also makes your work more fun because you spend less time setting up!”}},{“@type”: “Question”,”name”: “How Can You Troubleshoot Common Issues That Arise During Lathe Motor Replacement?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To fix common problems when changing a lathe motor, start by checking the power supply. Make sure it’s plugged in and working. Next, look at all the wires for damage. If they are loose, tighten them. Lastly, if the motor doesn’t run, check the motor switch for issues. Always be careful and turn off the power when you work on it!”}},{“@type”: “Question”,”name”: “What Are The Best Practices For Maintaining A Lathe Motor And Tool Post To Ensure Optimal Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your lathe motor and tool post working great, start by cleaning them often. Dust and dirt can cause problems, so use a soft cloth or brush. Make sure to check for any loose parts and tighten them if needed. You should also lubricate moving parts with oil to help them run smoothly. Lastly, always follow the manufacturer’s instructions to keep everything safe and working well.”}}]}