Every metal lathe needs care to work well. One important task is the lathe oil change. Have you ever wondered why regular oil changes are essential for your metal lathe? Think of your lathe like a car. Just like a car needs fresh oil to run smoothly, your lathe needs proper lubrication too. Without it, parts can wear out quickly, leading to big problems.

Imagine trying to cut metal with a grumpy, noisy machine. That’s what happens if you ignore the oil change! A well-oiled lathe not only works better but lasts longer. It’s like giving your machine a special treat. Fun fact: Regularly changing lathe oil can even improve the quality of your work. Ready to dive deeper into this important topic? Let’s explore the benefits of maintaining your lathe with the right oil changes.

Essential Guide To Lathe Oil Change For Metal Lathe Use

Lathe Oil Change for Metal Lathes

Regular lathe oil changes keep your metal lathe running smoothly. Oil reduces friction and prevents rust, ensuring a longer lifespan for your machine. You should change the oil every few months, especially if you use it often. Have you noticed unusual noises? That could mean it’s time for an oil change! Surprisingly, fresh oil can improve performance dramatically, making your tasks easier. Proper maintenance, like changing the lathe oil, is key to quality work and reliability.

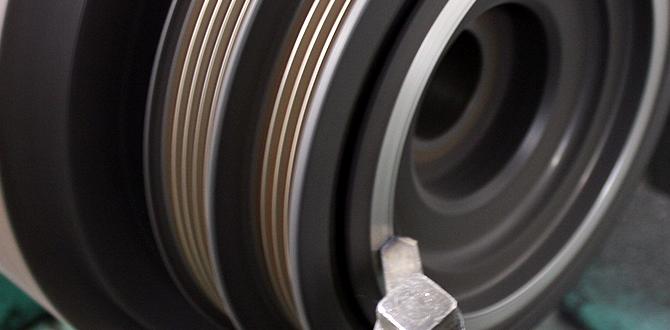

Understanding the Importance of Lathe Oil

Role of lathe oil in machine longevity. Effects of oil quality on machining precision.

Lathe oil is like a superhero for machines. It keeps everything running smoothly and makes your lathe last longer. Without good oil, parts wear out fast. This oil not only protects but also helps with precision. Imagine trying to cut a cake with a dull knife—it’s messy! Similarly, poor oil can lead to mistakes in machining. So, keep that lathe oiled up and happy!

| Oil Quality | Effects |

|---|---|

| High-quality oil | Improves precision |

| Poor-quality oil | Can cause errors |

Types of Lathe Oils Available

Mineral vs. synthetic lathe oils. Recommended brands and products.

Different types of lathe oil are made from two main types: mineral oil and synthetic oil. Mineral oils are common and often cheaper, but they may not last as long. On the other hand, synthetic oils can work better in tough conditions. They resist heat and wear, giving your lathe a longer life.

Here are some popular brands:

- Mobil Vactra – Known for high performance.

- Chevron – Offers good lubrication.

- Havoline – Great for daily use.

Choosing the right oil keeps your metal lathe running smoothly!

What is the best type of lathe oil?

The best type often depends on your needs. Synthetic oils generally offer superior performance and protection, especially under extreme conditions.

Popular Types:

- Mobil Vactra 2 – Great for high-load machines.

- Starrett M1 – Ideal for easy application.

Signs That It’s Time for an Oil Change

Indicators of old or degraded oil. Effects of neglecting oil changes on performance.

How can you tell if it’s time for an oil change? First, check for dark, thick oil. Fresh oil should be light and smooth, while old oil gets dark and gunky. You might also notice strange noises or a drop in machine speed. Ignoring this can lead to serious issues! Remember, less oil means more friction—like trying to skate on sandpaper! A regular oil change keeps your lathe running smoothly and saves money in the long run.

| Indicator | Effect of Neglect |

|---|---|

| Dark, thick oil | Increases friction and wear |

| Unusual noises | Poor performance and potential damage |

| Decrease in speed | Overheating and breakdowns |

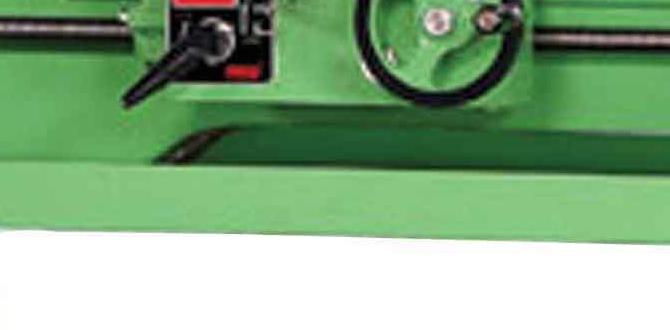

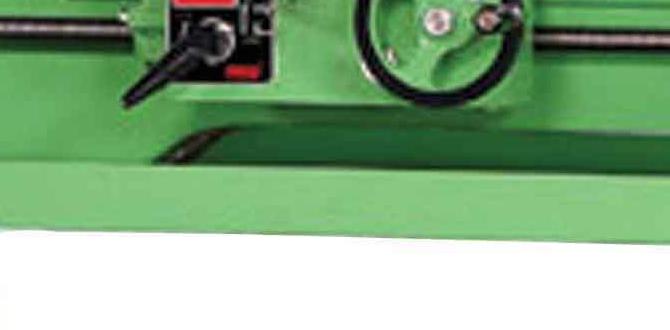

Step-by-Step Guide to Changing Lathe Oil

Necessary tools and materials. Detailed instructions for the oil change process.

Changing lathe oil is an important task to keep your machine running smoothly. You will need a few tools and materials. Here’s what you need:

- New lathe oil

- Oil container for old oil

- Wrench

- Rags or paper towels

To begin the oil change, first, turn off the lathe and unplug it for safety. Next, remove the oil drain plug. Let the old oil flow out into the container. After that, replace the drain plug securely. Finally, fill the machine with fresh lathe oil. Clean any spills with rags. Simple, right?

What tools do I need to change lathe oil?

You need new lathe oil, an oil container, a wrench, and rags.

Best Practices for Lathe Maintenance

Frequency of oil changes based on usage. Tips for monitoring oil condition.

Keeping your lathe in good shape means changing the oil regularly. If you use your lathe often, it’s wise to change the oil every 50 hours of work. For less regular use, every 100 hours is fine. Always check the oil’s color and smell to see if it needs changing. Clean oil is usually clear or light brown. Dark or smelly oil signals it’s time to change.

- Change oil every 50 hours for heavy use.

- Change oil every 100 hours for light use.

- Check for changes in color and smell.

- Use clean oil for best performance.

How often should I change lathe oil?

If you use your lathe heavily, change the oil every 50 hours. For lighter use, every 100 hours is sufficient.

Common Mistakes to Avoid When Changing Lathe Oil

Misapplying oil types. Ignoring manufacturer recommendations.

When changing lathe oil, watch out for common slip-ups. Misapplying the wrong oil can turn your smooth machine into a grumpy one. Always pick the oil your lathe likes best, or it might throw a tantrum! Ignoring the manufacturer’s advice is like ignoring a chef’s recipe; it usually leads to a messy outcome. Stick to the guidelines for happy machining!

| Common Mistakes | Effects |

|---|---|

| Using incorrect oil | Can cause wear and tear |

| Ignoring recommendations | May lead to machine failure |

FAQ About Lathe Oil Changes

Addressing common queries and concerns. Clarifying misconceptions about oil types and changes.

Many people have questions about changing oil in a metal lathe. Clarifying these can help ease concerns. Common issues include what oil to use and how often to change it. Some think any oil will work, but that’s not true. Using the wrong oil can damage the lathe. Here are some key points:

- Use specific lathe oil designed for metal lathes.

- Change oil regularly to keep the machine running smoothly.

- Check the manufacturer’s guidelines.

What oil should I use in a lathe?

The best choice is high-quality lathe oil made for metal lathes. This protects parts and ensures smooth operation.

How often should I change the oil?

It’s good to change the oil every 50 hours of use. Regular changes keep your lathe in top shape.

Additional Resources and Tools

Recommended reading materials. Links to instructional videos and forums for further assistance.

Want to learn more about lathe oil changes? You’re in luck! There are many great resources available. Books like “Metalworking 101” are a solid start. You can also dive into YouTube for fun and informative videos. Places like the Practical Machinist forum are perfect for asking questions and sharing tips with fellow enthusiasts. Check out the helpful table below for some top picks:

| Resource Type | Title/Link |

|---|---|

| Book | Metalworking 101 |

| Video | YouTube Lathe Maintenance |

| Forum | Practical Machinist |

So, whether you read, watch, or chat online, you’ll be a lathe oil expert before you know it! Remember, knowledge is your best tool—right after the lathe itself!

Conclusion

In summary, changing the oil in your metal lathe is crucial for smooth operation. It keeps the machine clean and running efficiently. Regular oil changes can extend your lathe’s life. Remember to check your manual for specific instructions. Let’s keep working safely and effectively! For more tips, read our guide on lathe maintenance.

FAQs

How Often Should The Oil In A Metal Lathe Be Changed For Optimal Performance?

You should change the oil in a metal lathe every 100 hours of use. If you use it a lot, check it more often. Clean oil helps the lathe run smoothly. Always follow the instructions from the machine’s manual. This will help keep your tools in great shape!

What Type Of Oil Is Best Suited For Use In A Metal Lathe?

The best oil for a metal lathe is called cutting oil. It helps the machine work smoothly. You can also use machine oil or way oil. These oils keep the metal cool and prevent rust. Always check the instructions for your specific lathe.

What Are The Signs That Indicate It’S Time To Change The Oil In My Lathe?

You should change the oil in your lathe if you see dark or dirty oil. If the oil looks thick or sludgy, it’s time for a change. You should also check if the oil smells bad or burns when you use the lathe. Lastly, if the lathe is making strange noises, it might need fresh oil.

Can I Use The Same Oil For Both Lubrication And Coolant In My Metal Lathe?

No, you shouldn’t use the same oil for both lubrication and coolant in your metal lathe. Lubrication helps moving parts work smoothly, while coolant keeps things cool and stops them from getting too hot. Using one oil for both jobs can cause problems. It’s best to use separate oils for each task to keep your machine working well.

What Is The Proper Procedure For Draining And Replacing Oil In A Metal Lathe?

To change the oil in a metal lathe, first, turn off the lathe and unplug it for safety. Next, find the oil drain plug and place a container under it to catch the old oil. Unscrew the plug to let the oil drain out completely. After that, replace the plug and fill the lathe with new oil using the fill port. Make sure to use the right type of oil for your lathe. Finally, check the oil level with a dipstick, if available, and clean up any spills.