Have you ever wondered how your metal lathe stays in great shape? Regular maintenance is key! One important part of that maintenance is the lathe oil change. This ensures that all moving parts stay smooth and work well together.

Imagine trying to ride a bike with rusty gears. It wouldn’t be fun or easy, right? A lathe works similarly. Without fresh oil, the machine can suffer. If your lathe is noisy or feels rough, it might need an oil change.

Then there’s the belt. A healthy belt keeps everything running smoothly. If it’s worn out, your lathe performs poorly. Keeping up with regular checks can save you time and money. It’s amazing how small steps can lead to better results! So, how often do you check your lathe oil change? Let’s dive into the details.

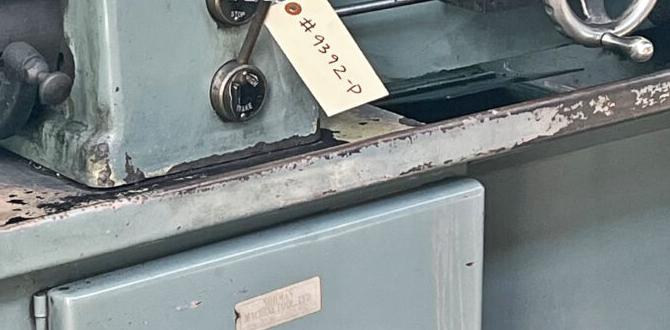

Lathe Oil Change: Essential Tips For Metal Lathe Belt Maintenance

Understanding Lathe Oil Change and Belt Maintenance

Changing lathe oil is crucial for keeping your metal lathe in top shape. Fresh oil lubricates the machine and prevents wear and tear. Have you ever noticed a machine running rough? Most often, it needs an oil change! Check the lathe belt as part of your maintenance. A worn belt can cause slippage and affect performance. Fun fact: Regular maintenance can prolong the life of your metal lathe. Simple actions keep it running smoothly and efficiently.Understanding the Importance of Lathe Oil

Role of lathe oil in machine performance. Consequences of neglecting oil changes.Lathe oil plays a vital role in keeping machines running smoothly. It reduces friction and heat, allowing parts to work together efficiently. Without regular oil changes, machines may wear out quickly. This can lead to costly repairs or replacements. Neglecting oil could cause:

- Overheating of parts.

- Increased noise and vibrations.

- Shorter lifespan of the lathe.

Why is changing lathe oil important?

Changing lathe oil is important for good machine health. It prevents damage and ensures smooth operation. Regular changes can significantly extend the life of your metal lathe.

What happens if you don’t change lathe oil?

- Parts can seize up.

- It may cause accidents.

Identifying the Right Type of Oil for Your Metal Lathe

Different types of lathe oils available. Choosing oil based on lathe manufacturer recommendations.Choosing the right oil for your lathe is essential for smooth operation. There are different types of oils available, such as synthetic and mineral oils. Always check your lathe’s manual for manufacturer recommendations. Using the wrong oil can damage your machine. Here are some oil types to consider:

- Mineral oil

- Synthetic oil

- Gear oil

Proper oil choice can extend your lathe’s life and improve performance.

How do I choose the right lathe oil?

Review your machine manual for suggestions. Always follow the guidelines to keep your lathe running well.

Signs It’s Time for an Oil Change

Visual indicators of oil degradation. Performance issues that signal an oil change.Watch for clear signs that it’s time for an oil change. First, look at the oil’s color. If it turns dark or muddy, it’s losing its effectiveness. Next, check for unusual sounds. Is your machine running louder than normal? That can signal trouble. Other signs include:

- Unexpected vibrations

- Difficulty in operation

- Increased temperatures

Addressing these issues promptly helps keep your lathe working smoothly.

What are the signs of contaminated oil?

Signs of contaminated oil include dark color, gritty texture, and strange odors. These changes mean it’s time for a change before they harm your machine.

What should you do if you notice these signs?

Act quickly! Stop using the machine and change the oil to avoid damage.

Step-by-Step Guide to Changing Oil in Your Metal Lathe

Preparation required before starting the oil change. Detailed procedure for safely changing oil.Before changing your lathe oil, prepare your workspace. Gather the right tools, like a wrench and a container for old oil. Make sure you wear gloves to protect your hands. Safety first! Turn off the machine and unplug it to avoid accidents.

Follow these steps for a safe oil change:

- Remove the old oil cap carefully.

- Drain the old oil into your container.

- Inspect the oil filter and replace it if needed.

- Add fresh oil according to the manufacturer’s instructions.

- Check for leaks before sealing the cap again.

That’s it! You’re ready to go back to work.

How often should you change oil in a metal lathe?

Change the oil in your lathe every 50 to 100 hours of use. This helps keep your lathe running smoothly.

Maintaining the Lathe Belt During Oil Changes

Importance of checking the belt condition. How oil affects the lathe belt and maintenance tips.Keeping the lathe belt in good shape is very important. The belt helps the lathe run smoothly. If it is damaged, it can make your work hard. Oil can affect the belt. If too much oil gets on the belt, it can slip or wear out faster. Regular oil changes help keep the belt clean. Here are some tips for maintenance:

- Check the belt for cracks or wear.

- Wipe oil off the belt after changes.

- Keep tension on the belt to avoid slipping.

- Listen for unusual sounds while the lathe runs.

How does oil affect my lathe belt?

Oil can cause the belt to slip or break down faster if it gets on its surface. Regular checks and cleanings can keep your lathe belt working well.

Frequency of Oil Changes Recommended for Metal Lathes

Factors that influence oil change frequency. General guidelines for routine maintenance.Keeping your metal lathe in top shape is key. Oil changes are like a spa day for your machine. The frequency of these changes depends on factors like usage, environment, and type of work. Generally, if you use your lathe daily, change the oil every month. For lighter use, every three months is fine. Also, remember to check the oil level regularly—it’s easier than finding a needle in a haystack! Here’s a handy guide:

| Usage Type | Oil Change Frequency |

|---|---|

| Heavy Usage | Monthly |

| Moderate Usage | Every 2-3 Months |

| Light Usage | Every 6 Months |

A well-oiled lathe not only runs smoother but also lasts longer. So keep that oil fresh like your favorite snack—nobody likes stale chips!

Common Mistakes to Avoid During an Oil Change

Missteps that can lead to machine damage. Best practices to ensure proper oil change.Changing oil in a lathe is essential, but mistakes can damage your machine. Follow these best practices to avoid problems:

- Choose the right oil type. Using the wrong one can harm your machine.

- Always check the oil level. Too much or too little can cause issues.

- Clean the area before changing oil. Dirt can mix with the oil.

- Dispose of old oil properly. This protects the environment.

Taking these steps can help your lathe last longer. Regular oil changes keep everything running smoothly.

What are common mistakes during oil changes?

Common mistakes include using the wrong oil, ignoring oil levels, and not cleaning the area before changing oil.

Frequently Asked Questions About Lathe Oil Changes

Common inquiries from lathe operators. Addressing myths versus facts about oil maintenance.Many lathe operators often wonder about oil changes. Here are some common questions and answers:

How often should I change lathe oil?

Change lathe oil every 6 months or after 100 hours of use. This keeps your machine running smoothly.

Do I need special oil for my lathe?

Yes, use lathe-specific oil. It protects the metal and ensures better performance.

Myths about lathe oil maintenance:

- Myth: You can use regular motor oil. Fact: This can harm your lathe over time.

- Myth: Oil changes are not necessary. Fact: Regular changes make your lathe last longer.

Remember these tips to keep your lathe in great shape!

Conclusion

In summary, changing the oil in your metal lathe is crucial for smooth operation. Regular oil changes keep your lathe’s parts working well and prevent damage. Check your lathe’s manual for oil types and change schedules. Make sure to inspect the lathe belt too, as a worn belt can affect performance. Keep learning and maintain your lathe for best results!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Oil Change For A Metal Lathe Belt:Sure! To change the oil in your metal lathe, first, turn off the machine and unplug it. Next, find the oil fill hole, usually on the side. Use a clean cloth to wipe away old oil. Then, pour in new lathe oil until it’s full. Finally, check that everything is sealed tight before you start working again.

Sure! Please tell me what question you want me to answer.

What Type Of Oil Is Recommended For Lubricating A Metal Lathe Belt And Other Moving Parts?You should use a light machine oil for a metal lathe. This type of oil helps keep the moving parts running smoothly. You can also use 3-in-1 oil, as it works well for machines. Just make sure not to use too much oil. A little bit goes a long way!

How Often Should You Change The Oil In A Metal Lathe To Ensure Optimal Performance?You should change the oil in your metal lathe every six months or after using it for 100 hours. Check the oil level regularly and look for dirt. If the oil looks dirty, it’s time to change it. Clean oil helps your lathe work better and last longer.

What Are The Signs That Indicate It’S Time To Change The Oil In My Lathe?You should change the oil in your lathe when it looks dark or dirty. If you hear strange noises while using it, that’s a sign too. Also, if your lathe seems to move slowly or gets stuck, it might need new oil. Checking the oil level often helps you know when to change it. Keeping the oil fresh keeps your lathe running well!

Can Using The Wrong Type Of Oil Affect The Performance Of The Lathe Belt?Yes, using the wrong oil can make the lathe belt work poorly. The belt might slip or not grip well. This can cause the machine to run slower or not work at all. It’s important to use the right oil for the best performance. Make sure you check the instructions for the right type.

What Is The Correct Procedure For Changing The Oil In A Metal Lathe?To change the oil in a metal lathe, first, turn off the machine and let it cool down. Then, place a container under the oil drain to catch the old oil. Next, open the oil drain and let the old oil flow out completely. After that, close the drain and fill it with new oil using a funnel. Finally, check the oil level to make sure it’s just right.