Have you ever wondered what keeps a metal lathe running smoothly? Just like a car needs oil, a metal lathe needs the right lathe oil for its parts to stay in shape. Changing the oil in your lathe is a simple and important task. It can help your machine last longer and work better. But how often should you do it?

Imagine working on a fun project, only to find your lathe is not operating right. That frustration can be avoided with regular maintenance. Changing the oil on your metal lathe bench is an easy job you can do yourself. Plus, it gives you a chance to check for other problems before they become big headaches.

Did you know that many hobbyists forget about this important step? A little oil can make a big difference in performance. In this article, we will explore how to change lathe oil and why it matters. Get ready to keep your metal lathe in top shape!

Lathe Oil Change: Essential Tips For Your Metal Lathe Bench

Lathe Oil Change for Metal Lathes

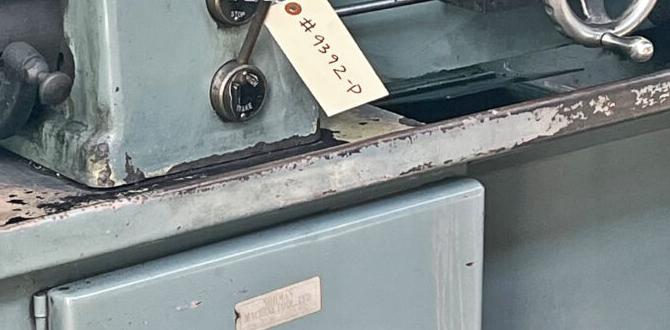

Changing the oil in a metal lathe is crucial for keeping it running smoothly. Without regular oil changes, the lathe can wear out faster than expected. Do you know what oil your lathe needs? Using the right type keeps the gears lubricated and reduces friction. A clean bench and organized tools make the process easier too. Always check your machine’s manual for specific instructions. Regular maintenance can extend its life and improve performance. Why wait? Start caring for your lathe today!Understanding the Importance of Lathe Oil

Explanation of how lathe oil affects machine performance. Effects of inadequate lubrication on metal lathe longevity.Lathe oil plays a key role in how a metal lathe works. Good lubrication helps parts move smoothly. Without enough oil, machines can wear out faster. This can lead to costly repairs. Proper oil use keeps your lathe running longer. Here’s why lathe oil is so important:

- Proper lubrication prevents overheating.

- Reduces friction between moving parts.

- Extends lifespan of the machine.

- Improves safety while operating the lathe.

How does lathe oil affect performance?

Lathe oil increases efficiency by keeping parts well-lubricated, which reduces wear and tear.

What happens without enough lubrication?

Inadequate lubrication leads to increased friction, which can shorten the lathe’s life.

Identifying the Right Time to Change Lathe Oil

Signs indicating that lathe oil needs changing. Recommended frequency for oil changes based on usage.Knowing when to change lathe oil is important for keeping your machine running smoothly. Watch for these signs:

- Dark or cloudy oil color

- Unusual noise from the lathe

- Sticking parts or poor performance

If you use your lathe often, oil changes are best every 50 hours of use. For light use, change the oil every 100 hours. Following these tips helps maintain your lathe’s health!

How do I know when to change the lathe oil?

Look for dark oil, unusual noises, or poor performance. These signs mean it’s time for a change!

Step-by-Step Guide to Changing Lathe Oil

Detailed instructions for the oil change process. Safety precautions to consider during the oil change.Changing the oil in your lathe is important for keeping it running smoothly. Follow these steps for a safe and easy process:

- Turn off the lathe and unplug it.

- Gather your tools: a wrench, new oil, and a container for old oil.

- Locate the oil drain plug and remove it carefully.

- Let the old oil drain completely.

- Replace the drain plug and add new oil.

- Check the oil level before starting the lathe again.

For safety, always wear gloves and goggles. Make sure the work area is clean. This helps prevent accidents.

What are the safety precautions for changing lathe oil?

Wear protective gear like gloves and goggles. Keep the area clear to avoid slips. Unplug the lathe before starting, to prevent unexpected movement.

Common Mistakes to Avoid During Oil Changes

List of frequent errors made by users when changing lathe oil. Tips on how to prevent these mistakes.Changing lathe oil can seem simple, but many people slip up. First, they often forget to clean the oil pan. This can lead to dirty oil getting mixed in. Next, some folks pour the oil too quickly, causing spills that would make a toddler cry. Always use a funnel, and take your time! Also, don’t forget to check the oil level afterward—it’s not a guessing game! Here’s a quick table of common mistakes and how to dodge them:

| Common Mistakes | Tips to Prevent |

|---|---|

| Skipping the cleaning | Always clean the pan before changing oil. |

| Pouring too quickly | Use a funnel and go slow. |

| Ignoring level checks | Check the level after pouring. |

A little care goes a long way. If you follow these tips, your lathe will thank you, and maybe even take you out to dinner! (Just kidding!)

Maintenance Tips for Optimal Lathe Performance

Additional maintenance practices that complement oil changes. Importance of regular inspections and cleanings.Keeping your metal lathe in top shape means more than changing the oil. It needs regular attention too. Here are some tips to help:

- Check belts for wear. Worn belts can slip and cause problems.

- Clean the area around your lathe. Dust and debris can affect its performance.

- Inspect the power cord. A damaged cord can be a safety risk.

Regular cleanings and checks keep your lathe running smoothly. Try to inspect it often. This way, you catch issues early, ensuring you have a reliable tool.

What other maintenance should I do for my lathe?

Other maintenance includes checking the belts, cleaning around the lathe, and inspecting the power cord. Regular checks prevent bigger problems later.

Frequently Asked Questions About Lathe Oil Changes

Common queries regarding lathe oil changes. Expert answers that clarify user concerns.Many people wonder about lathe oil changes. Here are some common questions and answers to help clear things up.

How often should I change lathe oil?

It’s best to change your lathe oil every 40 to 100 hours of use. It keeps everything running smooth!

What happens if I don’t change the oil?

If you delay changing the oil, it can lead to damage and poor performance of the lathe.

What type of oil should I use?

Use a high-quality lathe oil recommended by your lathe manufacturer.

What are the signs that I need to change the oil?

- The oil looks dark or dirty.

- You hear strange noises while using the lathe.

- The lathe runs slower than normal.

Understanding these key points can help you keep your lathe in great shape.

Conclusion

In summary, changing lathe oil is essential for your metal lathe’s smooth operation. Regular oil changes help keep your machine running well and prevent wear. You should check the oil regularly and replace it when needed. For more details, consider reading maintenance guides or watching tutorial videos. Taking these steps will keep your lathe in top shape and help you work better!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Oil Change For A Metal Lathe Bench:Sure! Here are the answers to your questions about changing lathe oil. 1. **Why do we change lathe oil?** We change lathe oil to keep the machine running smoothly. Fresh oil helps protect metal parts and stops rust. 2. **How often should we change the oil?** We should change the oil every few months or whenever it looks dirty. This keeps the lathe in good shape. 3. **What tools do we need to change the oil?** You need a container to catch the old oil, a funnel, and a cloth to clean up. 4. **How do we change the oil?** First, drain the old oil into a container. Then, put fresh oil in using the funnel. 5. **Where do we put the used oil?** We should take the used oil to a recycling center. They can help recycle it properly.

Sure! Just let me know what question you’d like me to answer.

What Is The Recommended Interval For Changing The Oil In A Metal Lathe?You should change the oil in a metal lathe about every 100 hours of use. If you use it less often, change the oil at least once a year. This keeps everything running smoothly. Always check the oil level and color to make sure it’s still good. Taking care of the lathe helps it last longer.

What Type Of Oil Is Best For Use In A Metal Lathe, And Are There Specific Brands You Would Recommend?The best oil for a metal lathe is a type called machine oil or spindle oil. It helps the parts move smoothly without creating too much heat. Some good brands you can use are Mobil, Mobil 1, and 3-In-One oil. Always check the oil’s label to make sure it’s safe for your lathe.

How Do You Properly Drain And Refill The Oil In A Metal Lathe?To drain the oil in a metal lathe, you first need to find the oil drain plug, usually at the bottom. Use a container to catch the old oil when you unscrew this plug. After the oil is fully drained, screw the plug back in tightly. Then, find the oil fill hole on the lathe and add new oil until it reaches the correct level. Make sure to close the fill hole securely when you finish!

Are There Any Specific Maintenance Steps To Take After Changing The Oil In A Lathe?After you change the oil in a lathe, you should check the oil level. Make sure it’s at the right spot. Clean up any spills or messes. Also, run the lathe for a few minutes to let the new oil spread. Finally, check for any unusual sounds or leaks while it’s running.

What Signs Indicate That The Oil In A Metal Lathe Needs To Be Changed?You might need to change the oil in a metal lathe if it looks dirty or has a strange color. If you see a strong smell or foam on the surface, that’s also a sign. The oil should be clear and smooth, not gritty or thick. You should check the oil regularly to keep the lathe working well.