Have you ever wondered how often you should change the oil in your metal lathe? Just like a car needs fresh oil, your lathe benefits from regular maintenance. A simple lathe oil change can keep the machine running smoothly. This is important for those who love using CAD design to create intricate projects.

Many hobbyists overlook this key step. They might think it’s not necessary or too complicated. But, it’s easy! All you need is the right oil and a few minutes of your time. Did you know that using the right oil can even improve your CAD designs? It can help you achieve cleaner cuts and better surfaces.

Maintaining your lathe isn’t just about keeping it running; it’s about getting the best results from your designs. So, are you ready to learn how to make your metal lathe last longer and work better? Let’s explore how to change the oil like a pro and elevate your CAD projects!

Lathe Oil Change For Metal Lathe Cad Design Efficiency

Lathe Oil Change for Metal Lathes in CAD Design

Maintaining a **metal lathe** is crucial for its performance. Regular **lathe oil changes** keep machinery running smoothly. Did you know that using the right oil can extend the life of your tools? Also, **CAD design** can help you visualize the parts you need. Imagine designing precise components for your project! Choosing the right oil and maintaining it through proper design ensures your lathe works at its best. Keeping everything well-oiled keeps your creativity flowing!Understanding the Importance of Lathe Oil

Explanation of lubrication in metal lathes. Benefits of regular oil changes for machine performance.Lubrication keeps metal lathes happy and running smoothly. It’s like giving them a nice spa day! Regular oil changes help in reducing wear and tear, so your machine performs at its best. This can even make it last longer, saving you money in the long run. Imagine a well-oiled lathe as a superhero—always ready to save the day with precision and power.

| Benefit | Explanation |

|---|---|

| Reduced Friction | Less wear and tear on parts. |

| Improved Performance | Smoother operation for better results. |

| Extended Lifespan | Your lathe could last longer. |

Signs That Your Lathe Oil Needs Changing

Visual indicators of oil condition. Performance issues related to oil quality.It’s important to notice changes in lathe oil. Here are signs that it needs changing:

- Oil color: Dark or cloudy oil is a sign of wear.

- Odor: If the oil smells burnt, it’s time to replace it.

- Performance: If your lathe runs sluggishly, low-quality oil may be the issue.

- Noise: Unusual sounds can signal oil problems.

Checking these signs can help keep your machine running well.

What are some common signs of oil needing an oil change?

Common signs include: changes in color, strange smells, and poor machine performance. Always pay attention to your lathe’s sound and feel. Regular maintenance helps prevent issues.

Tools Needed for Lathe Oil Change

List of essential tools and equipment. Recommended oil change kits for metal lathes.Before you dive into changing lathe oil, gather your trusty tools. First, you’ll need a wrench set to open those stubborn oil plugs. A good drain pan helps catch the old oil and not your shoes. Don’t forget some rags for messes—because, let’s be honest, spills happen! For a smoother experience, consider a lathe oil change kit. They have everything you need, all packed with love (or at least oil). Here’s a quick list:

| Tool | Purpose |

|---|---|

| Wrench Set | Opening oil plugs |

| Drain Pan | Catching old oil |

| Rags | Wiping spills |

| Oil Change Kit | All-in-one solution |

Happy lathe oil swapping!

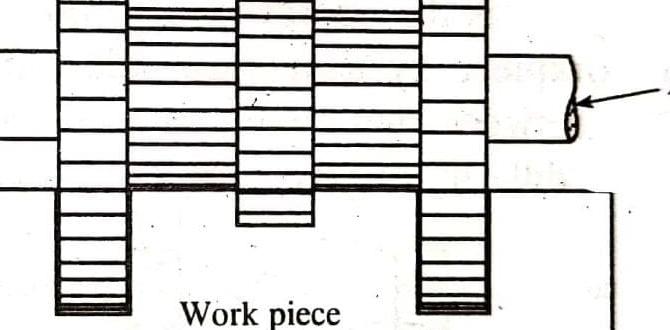

Step-by-Step Guide to Changing Lathe Oil

Detailed process for draining old oil. Instructions for applying new oil.Changing the oil in your lathe is important for its health. Start by ensuring the lathe is off and cool. Find the oil drain plug and place a bucket underneath it. Unscrew the plug slowly to let the old oil drain out. After that, replace the plug securely.

Next, use a funnel to add new oil. Choose the oil suitable for your lathe type. Ensure it fills to the correct level. Check regularly to keep everything running smoothly.

How often should you change lathe oil?

Change lathe oil every 100 hours of use or at least once a month. This keeps the machine running well and extends its life.Steps to Change Lathe Oil:

- Turn off and cool down the lathe

- Position a bucket under the drain plug

- Remove the drain plug and let old oil out

- Put the drain plug back on

- Add new oil with a funnel

- Check oil levels regularly

Best Practices for Maintaining Lathe Oil Quality

Tips for monitoring and maintaining oil levels. Recommended schedules for oil changes based on usage.Keeping lathe oil clean is important for a smooth-running machine. Regularly check your oil levels and watch for any changes in color. Dark or cloudy oil means it’s time for a change. You can follow these tips:

- Check oil levels weekly.

- Change oil every 40 hours of use.

- Always keep a log of oil changes.

Sticking to this schedule helps your lathe perform its best!

How do I know when to change lathe oil?

Change the oil when it looks dirty or after every 40 hours of work. This keeps things running smoothly!

Integrating CAD Design in Lathe Maintenance

Utilizing CAD software for maintenance planning. Designing parts using CAD that optimize lubrication needs.Using CAD software makes maintaining lathes easier. It helps plan better. With CAD, you can design parts that fit perfectly and need less lubrication. This saves time and oil. CAD designs can even show you where oil should go. Less mess means a cleaner workspace!

Why is CAD important for lathe maintenance?

CAD is vital because it allows for precise designs, improving performance. It helps in identifying lubrication spots accurately. This leads to effective maintenance and longer-lasting machines.

Key Benefits of Using CAD in Maintenance:

- Improved accuracy in designs

- Reduced oil waste

- Clean and efficient workspace

- Better planning for maintenance tasks

Common Mistakes to Avoid When Changing Lathe Oil

Missteps that can lead to machine damage. How to recognize and correct improper oil maintenance practices.Changing lathe oil can be tricky. Avoid these common mistakes to keep your machine healthy:

- Not checking oil levels regularly. Low oil can harm your lathe.

- Using the wrong type of oil. It’s important to use recommended oil for your machine.

- Ignoring oil color. Dark or muddy oil means it’s time for a change.

- Skipping the oil filter change. A clean filter helps your lathe run better.

Recognizing these issues will help you maintain your lathe properly. Regular checks can save you expensive repairs later!

How often should you change lathe oil?

For many machines, changing lathe oil every three to six months is best. This keeps your lathe smooth and safe.

Frequently Asked Questions (FAQs) About Lathe Oil Changes

Common queries regarding oil types and maintenance frequency. Expert tips for novice metal lathe users.Many beginners have questions about changing oil in their metal lathe. It’s important to choose the right oil and know how often to change it. Regular maintenance helps keep your lathe running smoothly.

What type of oil should I use for my lathe?

Choose lathe oil designed for metalworking. Using the right oil protects your machine and improves performance.

How often should I change the oil?

Change the oil every 50 to 100 hours of use or once a month, whichever comes first. This keeps everything clean.

Expert Tips for Novice Metal Lathe Users:

- Check the oil level regularly.

- Use clean tools to avoid contamination.

- Follow your machine’s manual for specific recommendations.

Regular oil changes are key to your lathe’s health. Following these simple tips makes it easier and ensures a longer life for your lathe.

Conclusion

In summary, changing lathe oil is important for keeping your metal lathe running smoothly. Proper oil helps reduce friction and wear. When designing with CAD, you can plan your lathe projects better. Remember to check your lathe regularly and change the oil as needed. For more tips, explore guides on lathe maintenance and CAD design to improve your skills!FAQs

What Are The Recommended Types Of Lathe Oil For Maintaining A Metal Lathe, And How Do They Differ In Terms Of Viscosity And Application?For keeping a metal lathe in good shape, you can use different types of lathe oil. Light oils are thin and great for moving parts. Heavy oils are thicker and good for protecting against rust. You should choose oil based on where you’re using it. Thinner oil moves easily, while thicker oil lasts longer.

How Can Cad Software Be Utilized To Create A Design For A Lathe Oil Change System That Improves Efficiency And Reduces Oil Waste?You can use CAD software to draw a new oil change system. First, you design a way to catch all the oil. Then, you make sure it’s easy to drain and refill the oil quickly. Next, you can test your design to see if it works better than old systems. This helps you save oil and makes the job faster!

What Are The Critical Components To Consider When Designing A Lathe Oil Reservoir In Cad To Ensure Optimal Lubrication For A Metal Lathe?When designing a lathe oil reservoir, we must think about a few important parts. First, the size should hold enough oil for smooth working. Next, the shape should let oil flow easily to all parts. We also need to add a filter to keep dirt out. Finally, we should ensure the reservoir is easy to check and refill.

How Often Should Lathe Oil Be Changed In A Metal Lathe, And What Factors Influence This Maintenance Schedule?You should change the lathe oil regularly, usually every few months. This depends on how much you use the lathe. If you use it a lot or for heavy work, change the oil more often. Other factors, like the type of oil and the work you do, also affect how often you should check it. Always keep an eye on the oil’s condition!

What Best Practices Should Be Followed For Safely Disposing Of Used Lathe Oil, And How Can Cad Models Assist In Creating A Waste Management System?To safely dispose of used lathe oil, you should store it in a sealed container. Always label the container clearly. You can take it to a recycling center that accepts oil. Never pour it down the drain or on the ground. CAD models, which are computer drawings, help us design a good waste management system by showing how to set up recycling areas and containers. This makes it easier for everyone to follow safe disposal methods.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Recommended Types Of Lathe Oil For Maintaining A Metal Lathe, And How Do They Differ In Terms Of Viscosity And Application? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For keeping a metal lathe in good shape, you can use different types of lathe oil. Light oils are thin and great for moving parts. Heavy oils are thicker and good for protecting against rust. You should choose oil based on where you’re using it. Thinner oil moves easily, while thicker oil lasts longer.”}},{“@type”: “Question”,”name”: “How Can Cad Software Be Utilized To Create A Design For A Lathe Oil Change System That Improves Efficiency And Reduces Oil Waste? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can use CAD software to draw a new oil change system. First, you design a way to catch all the oil. Then, you make sure it’s easy to drain and refill the oil quickly. Next, you can test your design to see if it works better than old systems. This helps you save oil and makes the job faster!”}},{“@type”: “Question”,”name”: “What Are The Critical Components To Consider When Designing A Lathe Oil Reservoir In Cad To Ensure Optimal Lubrication For A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When designing a lathe oil reservoir, we must think about a few important parts. First, the size should hold enough oil for smooth working. Next, the shape should let oil flow easily to all parts. We also need to add a filter to keep dirt out. Finally, we should ensure the reservoir is easy to check and refill.”}},{“@type”: “Question”,”name”: “How Often Should Lathe Oil Be Changed In A Metal Lathe, And What Factors Influence This Maintenance Schedule? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should change the lathe oil regularly, usually every few months. This depends on how much you use the lathe. If you use it a lot or for heavy work, change the oil more often. Other factors, like the type of oil and the work you do, also affect how often you should check it. Always keep an eye on the oil’s condition!”}},{“@type”: “Question”,”name”: “What Best Practices Should Be Followed For Safely Disposing Of Used Lathe Oil, And How Can Cad Models Assist In Creating A Waste Management System? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To safely dispose of used lathe oil, you should store it in a sealed container. Always label the container clearly. You can take it to a recycling center that accepts oil. Never pour it down the drain or on the ground. CAD models, which are computer drawings, help us design a good waste management system by showing how to set up recycling areas and containers. This makes it easier for everyone to follow safe disposal methods.”}}]}