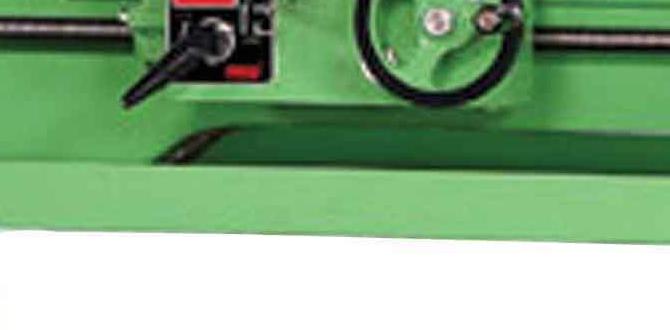

Imagine your metal lathe is running perfectly, but it suddenly slows down. What went wrong? One common issue is the need for a lathe oil change. Regularly changing the oil keeps your machine in great shape.

Many people overlook the importance of maintaining their lathe chuck. Did you know that dirty oil can lead to bigger problems? It can make parts wear out faster and affect performance.

Changing the lathe oil doesn’t have to be hard. In fact, it’s a simple task that anyone can learn. By taking a few minutes to care for your lathe, you can save time and money in the future. Just think about how smoothly your machine could run after a good oil change!

In the following article, we will explore how to do this important task. You’ll learn tips and tricks that make oil changing easy. So, let’s dive into the world of lathe oil change and discover how to keep your metal lathe chuck in top condition!

Lathe Oil Change: Essential Tips For Metal Lathe Chuck Maintenance

Understanding Lathe Oil Change for Metal Lathe Chuck

Changing lathe oil is essential for keeping your metal lathe chuck in good shape. Fresh oil reduces friction, which means less wear and tear. Have you ever wondered why some machines run smoother than others? Clean oil is the secret! It helps maintain temperature and protects metal parts from rust. Regularly checking and changing the oil can extend the life of your lathe and improve performance. Stay on top of maintenance, and your projects will look better and last longer!Understanding Lathe Oils

Types of lathe oils available in the market. Importance of using the right oil for different lathe components.There are different types of lathe oils, and knowing which to use can help your lathe run smoothly. Some oils are made for specific parts, while others can do a little bit of everything. Using the right oil is like giving your lathe a comfy bed! For example, light oils are great for quick work, while heavier oils can handle tough jobs. Remember, it’s important to choose wisely to avoid a squeaky lathe. And who wants to listen to that all day?

| Type of Lathe Oil | Best For |

|---|---|

| Light Oil | General lubrication |

| Heavy Oil | Heavy-duty machinery |

| Cutting Oil | Precision cutting tasks |

| Grease | Long-lasting protection |

So, spill the beans: are you ready to change that lathe oil? It’s not rocket science, but it can save your tools from a slippery disaster!

Signs That Your Lathe Oil Needs Changing

Indicators of oil degradation. Effects of old oil on performance and longevity of the lathe.Pay attention to your lathe oil. Several signs tell you it may need a change. Look for the color. If it’s dark or cloudy, it’s time for new oil. Smell it, too. A burnt odor means it’s old. Old oil hurts your lathe’s performance and lifespan. It can lead to:

- Poor lubrication

- Overheating

- Increased wear on parts

Keep an eye on these signs to help your lathe run smoothly.

How do you know when to change lathe oil?

Watch for dark color, bad smells, or strange noises. Regular checks help keep your lathe healthy.

Step-by-Step Guide to Changing Lathe Oil

Necessary tools and materials for the oil change. Detailed procedure to drain and refill lathe oil.Before changing lathe oil, gather your tools! You’ll need a wrench, a container for the old oil, a funnel, and, of course, fresh lathe oil. Think of it as a fun cooking show, but for machines! First, drain the old oil by locating the drain plug. Unscrew it and let the oil flow into your container. Be sure to avoid a slippery floor that could make a dancer out of you! Once it’s empty, replace the plug. Then, refill with new oil using the funnel. Voilà! Your lathe is now happy and ready to work again. Remember, like changing a light bulb, it’s much easier with a buddy!

| Tools and Materials |

|---|

| Wrench |

| Container for old oil |

| Funnel |

| Fresh lathe oil |

Maintaining Your Metal Lathe Chuck

Importance of regular maintenance for chucks. Best practices for cleaning and lubricating your lathe chuck.Keeping your metal lathe chuck in tip-top shape is like brushing your teeth. It’s necessary but can be a little boring! Regular maintenance is important because it helps your chuck last longer and work better. Clean it often to avoid dirt buildup. Lubricate it with lathe oil for smooth operation. Remember, even the toughest chucks need a little pampering!

| Best Practices | Description |

|---|---|

| Clean Regularly | Use a soft cloth to wipe away chips and grime. |

| Oil It Up | Apply lathe oil to keep moving parts lubricated. |

| Check for Damage | Look for cracks or wear to prevent bigger problems. |

In the end, a little care goes a long way. It’s like giving your chuck a spa day without the cucumbers on the eyes!

Choosing the Right Oil for Your Lathe Chuck

Factors to consider when selecting oil for chuck maintenance. Recommended oils for specific types of lathe chucks.Picking the best oil for your lathe chuck is like choosing the right topping for your pizza—get it wrong and it’s all slippery! First, consider the type of metal in your chuck. Different materials need different oils. Always check the manufacturer’s advice, like a restaurant critic checking the menu. Here’s a handy table to guide you:

| Chuck Type | Recommended Oil |

|---|---|

| Cast Iron | Mineral Oil |

| Steel | Synthetic Oil |

| Aluminum | Vegetable Oil |

Remember, oil helps reduce wear and tear! It keeps your lathe chuck running smoothly, which is crucial for precision work. A little oil can save you from a big headache down the road. Choose wisely, and your lathe will thank you!

Common Mistakes During Lathe Oil Change

Errors to avoid when changing oil. Consequences of neglecting proper oil change practices.Changing lathe oil can be tricky. Many make mistakes that could harm the machine. One big error is not cleaning the area first. Dust can mix with the oil, causing damage. Another mistake is using the wrong type of oil, leading to poor performance. Neglecting oil changes can wear out parts and lower efficiency. This can mean expensive repairs!

- Always clean the area before changing oil.

- Use the right kind of oil.

- Change oil regularly to avoid problems.

What happens if you don’t change lathe oil?

It can cause severe damage, leading to costly repairs. Proper oil change practices keep your lathe running smoothly.

FAQs About Lathe Oil Change

Frequently asked questions regarding the oil change process. Clarifications on the maintenance of metal lathe chucks.Many users have questions about changing lathe oil. Understanding the right steps is key for smooth operation. Regular oil changes keep your machine running well. Here are some common questions answered:

How often should I change my lathe oil?

Change your lathe oil every 100 hours of use or at least every six months. This helps in maintaining the machine.

What type of oil should I use?

Use high-quality machine oil that’s recommended by your lathe’s manufacturer. This ensures the machine works effectively.

How do I clean the metal lathe chuck?

- Use a soft cloth to wipe down the chuck. This helps remove dust and grime.

- Inspect for damage regularly. Check for wear and tear to avoid issues.

Taking care of your lathe oil and chuck is essential. It extends the life of your tools and keeps your work quality high!

Conclusion

In summary, changing the lathe oil is crucial for keeping your metal lathe chuck running smoothly. Regular maintenance helps prevent wear and tear. You should check the oil often and replace it when needed. This simple step improves your lathe’s performance. So, take care of your tools! For more tips, keep reading about lathe maintenance. Your projects will thank you!FAQs

Sure! Here Are Five Related Questions About Lathe Oil Changes And Metal Lathe Chucks:Sure! Here are five questions about lathe oil changes and metal lathe chucks. 1. Why do we need to change lathe oil? Changing lathe oil keeps the machine running smoothly. It helps the lathe parts stay clean and cool. 2. How often should you change the lathe oil? You should change the lathe oil every three to six months. It depends on how much you use the machine. 3. What happens if you forget to change the oil? If you forget, the lathe might not work well. The oil can get dirty and cause problems. 4. What is a metal lathe chuck? A chuck is a part that holds the metal piece while you work on it. It keeps the metal steady. 5. How do you take care of the lathe chuck? You can clean the chuck regularly. Make sure it’s free of dirt and oil for better performance.

Sure! Please give me the question you’d like me to answer.

What Are The Signs That Indicate It’S Time To Change The Lathe Oil In A Metal Lathe?You should change the lathe oil when it looks dirty or turns dark. If you hear strange sounds while the lathe runs, that’s a sign too. You might also notice the machine isn’t running smoothly. Lastly, if the oil smells bad or feels thick, it’s time for a change. Keeping the oil fresh helps the lathe work better!

How Often Should You Perform A Lathe Oil Change For Optimal Performance Of The Metal Lathe Chuck?You should change the oil in your lathe every six months to keep it working well. If you use it a lot, check the oil every three months. This helps the lathe stay clean and run smoothly. Always follow the instructions in the user manual for the best results.

What Type Of Oil Is Recommended For Use In Metal Lathe Chucks, And Does It Vary By Manufacturer?For metal lathe chucks, it’s best to use light machine oil. This kind of oil helps keep things moving smoothly. Different manufacturers may suggest different oils, so it’s good to check their instructions. Always follow what the maker of your lathe says for the best results!

What Is The Proper Procedure For Changing The Oil In A Lathe Chuck To Ensure Smooth Operation?To change the oil in a lathe chuck, first, turn off the machine. Next, find the oil drain plug and open it to let the old oil out. After that, clean the inside with a cloth. Then, pour in fresh oil through the fill hole. Finally, check that everything works smoothly before using the lathe again.

Are There Any Specific Maintenance Tips For Keeping The Metal Lathe Chuck In Good Condition After An Oil Change?Yes, there are some tips! After changing the oil, clean the chuck to remove any dirt. You can use a soft cloth for this. Check the moving parts to make sure they work well. Also, remember to oil them lightly. Finally, keep the area around the chuck tidy so nothing gets in the way.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions About Lathe Oil Changes And Metal Lathe Chucks:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about lathe oil changes and metal lathe chucks. 1. Why do we need to change lathe oil? Changing lathe oil keeps the machine running smoothly. It helps the lathe parts stay clean and cool. 2. How often should you change the lathe oil? You should change the lathe oil every three to six months. It depends on how much you use the machine. 3. What happens if you forget to change the oil? If you forget, the lathe might not work well. The oil can get dirty and cause problems. 4. What is a metal lathe chuck? A chuck is a part that holds the metal piece while you work on it. It keeps the metal steady. 5. How do you take care of the lathe chuck? You can clean the chuck regularly. Make sure it’s free of dirt and oil for better performance.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please give me the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Signs That Indicate It’S Time To Change The Lathe Oil In A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should change the lathe oil when it looks dirty or turns dark. If you hear strange sounds while the lathe runs, that’s a sign too. You might also notice the machine isn’t running smoothly. Lastly, if the oil smells bad or feels thick, it’s time for a change. Keeping the oil fresh helps the lathe work better!”}},{“@type”: “Question”,”name”: “How Often Should You Perform A Lathe Oil Change For Optimal Performance Of The Metal Lathe Chuck?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should change the oil in your lathe every six months to keep it working well. If you use it a lot, check the oil every three months. This helps the lathe stay clean and run smoothly. Always follow the instructions in the user manual for the best results.”}},{“@type”: “Question”,”name”: “What Type Of Oil Is Recommended For Use In Metal Lathe Chucks, And Does It Vary By Manufacturer?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For metal lathe chucks, it’s best to use light machine oil. This kind of oil helps keep things moving smoothly. Different manufacturers may suggest different oils, so it’s good to check their instructions. Always follow what the maker of your lathe says for the best results!”}},{“@type”: “Question”,”name”: “What Is The Proper Procedure For Changing The Oil In A Lathe Chuck To Ensure Smooth Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To change the oil in a lathe chuck, first, turn off the machine. Next, find the oil drain plug and open it to let the old oil out. After that, clean the inside with a cloth. Then, pour in fresh oil through the fill hole. Finally, check that everything works smoothly before using the lathe again.”}},{“@type”: “Question”,”name”: “Are There Any Specific Maintenance Tips For Keeping The Metal Lathe Chuck In Good Condition After An Oil Change?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there are some tips! After changing the oil, clean the chuck to remove any dirt. You can use a soft cloth for this. Check the moving parts to make sure they work well. Also, remember to oil them lightly. Finally, keep the area around the chuck tidy so nothing gets in the way.”}}]}