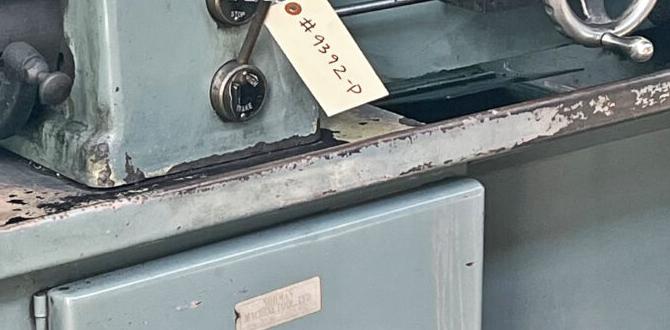

Have you ever wondered how metal lathes work? These amazing machines shape metal pieces into various parts we use every day. Just like any machine, they need care to run smoothly.

One essential part of keeping a lathe in good shape is changing the oil. Regular lathe oil changes keep everything running well. Imagine your bike after a good oil change—it goes so much faster and smoother, right?

The metal lathe bears a similarity. It needs fresh oil to perform at its best. A simple tool, the lathe chuck key, helps you tighten or loosen parts of the lathe. But how often do you think about these little things?

In this article, we will explore why changing lathe oil is so important. Plus, we’ll look closer at the lathe chuck key and its role in your projects. Are you ready to make your lathe work even better? Let’s dive in!

Lathe Oil Change: Essential For Metal Lathe Chuck Key Maintenance

Lathe Oil Change: A Simple Guide

Changing the lathe oil is crucial for keeping your metal lathe running smoothly. Oil protects the moving parts and prevents wear. It’s like giving your lathe a refreshing drink! Don’t forget the chuck key. It tightens the chuck, securing your workpiece. If you lose it, your work can slip and become messy. Keeping both oil and chuck key in good condition helps ensure safety and accuracy. Have you ever thought about how a little oil can make a big difference? Regular maintenance makes your lathe last longer.What is Lathe Oil and Its Importance

Explanation of lathe oil types and their properties. Importance of regular oil changes for machine longevity.Lathe oil is a special lubricant for machines. It comes in different types, like mineral oil and synthetic oil. Mineral oil is natural, while synthetic oil is man-made and often lasts longer. Using the right lathe oil keeps machines running smoothly.

Regular oil changes are important for machine health. Dirty oil can create wear and tear. Keeping your lathe clean helps it last longer. It’s like giving your bike a tune-up. Change the oil often to keep it happy.

Why is regular lathe oil change necessary?

Regular oil changes prevent damage and keep your lathe running effectively. This maintenance saves money and time in the long run.

Key Points:

- Clean oil reduces friction.

- Long-lasting machines save money.

- Ensures smooth operation.

Signs That Lathe Oil Needs Changing

Indicators of old or contaminated oil. Frequency of oil changes based on usage.Is your lathe feeling underwhelming? Look for some tell-tale signs that your oil is due for a change. First, check the color; if it’s darker than a cup of coffee, it might be time to replace it. Next, a strange smell could indicate contamination. If your lathe sounds like a grumpy cat, the oil might be tired. Lastly, consider how much you’ve been using it; the busier it gets, the more often you need to change the oil.

| Usage | Oil Change Frequency |

|---|---|

| Light Use | Every 6 months |

| Moderate Use | Every 3 months |

| Heavy Use | Monthly |

Step-by-Step Guide to Changing Lathe Oil

Tools and materials needed for the oil change. Detailed process for draining and replacing lathe oil.To change lathe oil, you’ll need a few tools. Gather your lathe oil, an oil drain pan, a funnel, and a wrench. First, turn off the lathe and unplug it. Remove the oil fill plug. Next, place the drain pan under the lathe. Use a wrench to unscrew the drain plug. Let the old oil flow out completely. After that, screw the drain plug back on. Finally, pour new oil in using the funnel. Replace the oil fill plug, and you’re done!

What tools are needed for changing lathe oil?

- Lathe oil

- Oil drain pan

- Funnel

- Wrench

How do you drain and replace the lathe oil?

**First, unplug your lathe.** Remove the oil fill plug and put the drain pan under the lathe. Unscrew the drain plug with a wrench. Let the oil drain out. Screw the drain plug back in, and pour in fresh oil. Replace the fill plug, too!

Choosing the Right Oil for Your Lathe

Different types of oils suitable for metal lathes. Factors to consider when selecting oil (temperature, viscosity).When picking oil for your lathe, think about a few important things. Different oils have different jobs. Some are great for warm days, while others shine in the cold. Viscosity is key too; it measures how thick or thin the oil is. Thicker oils can be like molasses on a chilly morning! Here’s a quick look at some oil types:

| Type of Oil | Best For |

|---|---|

| Synthetic Oil | High temperature |

| Mineral Oil | General use |

| Hydraulic Oil | Heavy tasks |

Consider your environment; warmer temps may need different oil than chilly spots. Always check labels for suitability. Choose wisely to keep your lathe running smoothly! After all, nobody likes a cranky lathe!

Proper Maintenance of Metal Lathe Chuck Keys

Importance of using the correct chuck key. Tips for maintaining and cleaning chuck keys.Using the right chuck key is important for safety and accuracy. A correct chuck key fits perfectly and makes it easier to hold your work steady. Here are some tips for keeping it in great shape:

- Always clean it after each use.

- Check for any damage regularly.

- Store it safely to avoid losing it.

- Apply lathe oil occasionally to keep it running smoothly.

These simple steps help you use your metal lathe chuck key safely and efficiently.

Why is it important to use the correct chuck key?

Using the correct chuck key ensures the right fit, improving safety and performance during work.

Tips for maintaining and cleaning chuck keys:

- Remove dirt and oil after each use.

- Inspect for wear and tear regularly.

- Keep it oiled to prevent rust.

Common Mistakes to Avoid During Oil Change

Common errors when changing lathe oil. How to avoid simple pitfalls to ensure optimal performance.Changing lathe oil is important for machine function. However, mistakes can happen. Avoid these common errors to keep your lathe working well:

- Not cleaning the area before starting. Dirt can contaminate oil.

- Using the wrong type of oil. Check your machine’s manual.

- Overfilling or underfilling the oil tank. Follow the guidelines.

- Forgetting to replace oil filters. Old filters can hold dirt.

Fixing these simple mistakes can help your lathe perform its best. Regular checks and proper care lead to a longer machine life.

What should I do first before changing lathe oil?

Always start by cleaning the work area. This protects your lathe from dirt and dust while you work.

FAQs About Lathe Oil and Chuck Key Usage

Answers to frequently asked questions. Clarifications on myths related to lathe maintenance.Many people have questions about lathe oil and chuck keys. Here are answers to some common ones:

How often should I change lathe oil?

It’s best to change your lathe oil every 100 hours of use or at least every six months. Fresh oil keeps your machine running smoothly.

Do I really need a chuck key?

Yes! A chuck key helps you tighten or loosen the chuck securely. Without it, you might damage the lathe.

Can I use any oil for my lathe?

No. Using the wrong oil can harm your lathe. Always use recommended lathe oil for the best results.

Common Myths:

- More oil means better performance. Not true! Too much oil can create a mess.

- All oils are the same. This is false! Different oils work for different machines.

Understanding these basics keeps your lathe in great shape. Regular maintenance is key to longevity.

Additional Tips for Metal Lathe Care

General maintenance practices for metal lathes. Importance of keeping tools and accessories in good condition.Keeping your metal lathe in great shape is easier than pie—well, almost! Regular maintenance is key. Check for dirt and dust regularly. A clean lathe works better. Don’t forget to change lathe oil to keep everything running smoothly. Also, ensure your tools and the metal lathe chuck key stay in top condition; they are your best friends in this metalworking journey. A good chuck key helps you avoid mishaps—nobody wants a surprise trip to the ER!

| Task | Frequency |

|---|---|

| Clean Lathe | Weekly |

| Change Oil | Monthly |

| Inspect Tools | Every Use |

| Check Chuck Key | Every Use |

Following these tips can save you time and trouble. Remember, a well-cared lathe is a happy lathe! And happy lathes make better chips – metal chips, that is!

Conclusion

In summary, changing lathe oil keeps your metal lathe running smoothly. Always check your lathe’s oil levels. Remember to use the right oil for the best results. Don’t forget to keep your chuck key nearby to adjust your workpieces easily. For more tips, keep exploring and reading about lathe maintenance. You’ll be a pro in no time!FAQs

What Type Of Oil Is Recommended For Changing The Lathe Oil In A Metal Lathe?For changing the oil in a metal lathe, we should use a light machine oil. This type of oil helps the lathe run smoothly. You might also see it called way oil. Always check your lathe’s manual for specific recommendations.

How Often Should The Lathe Oil Be Changed To Maintain Optimal Performance For A Metal Lathe?You should change the lathe oil every few months. It’s good to check it regularly. If you use your lathe a lot, change it often. Fresh oil helps the machine work better. Always remember to clean the area before adding new oil!

What Is The Best Method For Properly Cleaning And Lubricating A Metal Lathe Chuck Key?To clean a metal lathe chuck key, start by wiping it with a soft cloth. Use a little soap and water if it’s very dirty. Rinse it off and dry it well. After that, put a small drop of oil on it to keep it moving smoothly. Make sure to wipe away any extra oil.

Are There Specific Tools Or Equipment Needed For Changing Lathe Oil And Maintaining The Chuck Key?Yes, you need a few tools to change lathe oil and take care of the chuck key. You will need a wrench to open the oil drain plug. A container is useful for catching the old oil. For the chuck key, you might need some cleaning cloths and a small brush. This helps keep everything tidy and working well!

What Signs Indicate That The Lathe Oil Needs To Be Changed Or That The Chuck Key Requires Maintenance?You should change the lathe oil if it looks dirty or smells bad. If the lathe makes strange noises, that’s a sign too. For the chuck key, check for rust or stiff movement. If it’s hard to turn, it needs maintenance. Keeping them clean helps your tools work better!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Type Of Oil Is Recommended For Changing The Lathe Oil In A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For changing the oil in a metal lathe, we should use a light machine oil. This type of oil helps the lathe run smoothly. You might also see it called way oil. Always check your lathe’s manual for specific recommendations.”}},{“@type”: “Question”,”name”: “How Often Should The Lathe Oil Be Changed To Maintain Optimal Performance For A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should change the lathe oil every few months. It’s good to check it regularly. If you use your lathe a lot, change it often. Fresh oil helps the machine work better. Always remember to clean the area before adding new oil!”}},{“@type”: “Question”,”name”: “What Is The Best Method For Properly Cleaning And Lubricating A Metal Lathe Chuck Key?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To clean a metal lathe chuck key, start by wiping it with a soft cloth. Use a little soap and water if it’s very dirty. Rinse it off and dry it well. After that, put a small drop of oil on it to keep it moving smoothly. Make sure to wipe away any extra oil.”}},{“@type”: “Question”,”name”: “Are There Specific Tools Or Equipment Needed For Changing Lathe Oil And Maintaining The Chuck Key?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, you need a few tools to change lathe oil and take care of the chuck key. You will need a wrench to open the oil drain plug. A container is useful for catching the old oil. For the chuck key, you might need some cleaning cloths and a small brush. This helps keep everything tidy and working well!”}},{“@type”: “Question”,”name”: “What Signs Indicate That The Lathe Oil Needs To Be Changed Or That The Chuck Key Requires Maintenance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should change the lathe oil if it looks dirty or smells bad. If the lathe makes strange noises, that’s a sign too. For the chuck key, check for rust or stiff movement. If it’s hard to turn, it needs maintenance. Keeping them clean helps your tools work better!”}}]}