Have you ever wondered how to keep your metal lathe running smoothly? One simple key is regular lathe oil changes. Just like cars need oil to run well, metal lathes do too!

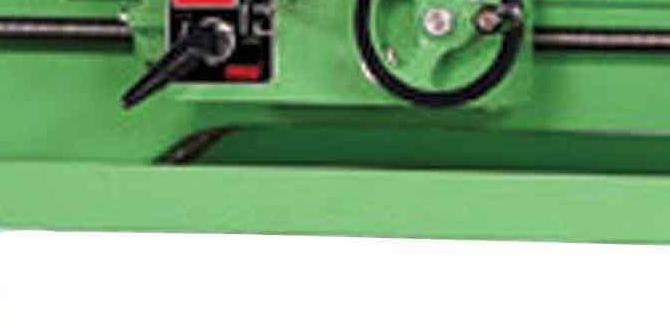

Imagine working on an exciting project, and suddenly your lathe starts acting up. Frustrating, right? But you can avoid this. Taking care of the compound rest on your lathe can make a big difference. Regular maintenance keeps your tools in great shape.

Did you know that the right oil can help prevent rust and wear? It’s true! Using the proper lathe oil helps the parts move easily. This means more fun and less hassle when you’re working. So, let’s dive into how you can change the oil and keep your metal lathe in top condition!

Essential Lathe Oil Change For Metal Lathe Compound Rest

Lathe Oil Change for Metal Lathe Compound Rest

Changing the lathe oil helps keep your metal lathe in great shape. Why is this important? Dirty oil can lead to rust and damage. It’s like giving your car an oil change; it ensures everything runs smoothly. Regular oil changes also improve the lathe’s accuracy. Did you know that proper oil maintenance can extend the machine’s lifespan? Don’t overlook this simple task! Your lathe will thank you with better performance and longevity.Importance of Regular Oil Changes

Benefits of maintaining a metal lathe. Impact on machine longevity and performance.Keeping your metal lathe in top shape is key. Regular oil changes help the machine work smoothly. Benefits include:

- Better performance.

- Longer machine life.

- Less wear and tear.

Machines that get regular oil changes last longer and run better. They avoid expensive repairs, saving you money. Think of it like changing oil in a car—it keeps everything running well!

Why is oil change important for metal lathe?

Regular oil changes keep your lathe safe and efficient. Without this, performance drops and repairs increase. The machine can also face more problems as parts wear out faster.

Signs That Your Lathe Oil Needs Changing

Visual indicators of oil deterioration. Performance issues related to poor lubrication.Has your lathe been acting grumpy lately? It might be time for an oil change! First, check for color changes. If the oil is dark or has thick gunk, it’s waving a red flag. Next, listen for any whispers of struggle. If your lathe starts making odd noises, it could be begging for better lubrication! Lastly, keep an eye on the performance. If it’s moving slower than a turtle in mud, you may need to replace that oil. Here’s a quick reference table:

| Signs of Oil Deterioration | Performance Issues |

|---|---|

| Dark or thick oil | Odd noises during operation |

| Unusual smell | Slow movement |

Tools Required for a Lathe Oil Change

List of essential tools and materials. Safety equipment to consider.Changing lathe oil is a careful task, and you need the right tools to do it correctly. First, gather the basics like an oil pump, drain pan, and wrenches. You’ll also want to have clean cloths on hand for any spills—or for wiping your brow if it gets messy!

Don’t forget your safety gear: goggles to protect your eyes and gloves to keep your hands safe. Because nobody wants an accidental bathed-in-oil moment! Here’s a quick look at what you need:

| Essential Tools | Safety Equipment |

|---|---|

| Oil pump | Goggles |

| Drain pan | Gloves |

| Wrenches | No-slip shoes |

With the right tools by your side, you’ll be ready to tackle that lathe oil change like a pro! Keep it safe, keep it tidy, and remember—no one likes a slippery floor or a slippery situation!

Step-by-Step Guide to Changing Lathe Oil

Preparing the workspace and lathe. Detailed procedures for draining and refilling oil.Start by getting your workspace ready. Make sure the lathe is turned off and unplugged. Then gather your tools, like a container to catch the old oil and a funnel for the new oil. Stay safe by wearing gloves!

Next, let’s change the oil:

- Find the oil drain plug. It’s usually at the bottom of your machine.

- Place your container under the plug and unscrew it. Let the old oil drain completely.

- Once drained, replace the plug and tighten it securely.

- Use a funnel to pour new oil into the fill hole. Check the manufacturer’s instructions for the right amount.

How often should you change lathe oil?

It’s good to change lathe oil every 50 hours of use or at least every month. This helps keep your lathe running smoothly!

Maintenance Tips for the Compound Rest

Best practices for keeping the compound rest in optimal condition. How frequently to inspect and maintain lubrication.To keep your compound rest working well, follow some simple tips. Regular checks and lubrication are key. Here’s how to maintain it:

- Inspect the compound rest weekly for dirt and wear.

- Clean it with a soft cloth to remove dust.

- Apply lathe oil about once a month.

- Keep moving parts free and well-lubricated.

Following these steps helps your lathe last longer and work better. Remember, a little care goes a long way!

How often should I oil my compound rest?

You should oil your compound rest once a month. This keeps it running smoothly and prevents rust. Regular lubrication is very important!

FAQs About Lathe Oil Changes

Commonly asked questions regarding oil types and maintenance. Expert answers to clarify common misconceptions.Got questions about keeping that lathe running smoothly? You’re not alone! Many people wonder what oil is best. The answer is simple: use a lightweight, high-quality oil. It helps everything function better. Some might think all oils are the same, but that’s like saying all ice cream is chocolate! Different oils suit different machines, so check your manual! Keep an eye on oil levels during maintenance, and your lathe will reward you by spinning like a pro. Need more info? Here’s a quick table:

| Question | Answer |

|---|---|

| What type of oil should I use? | Lightweight, high-quality oil is best! |

| How often should I change the oil? | Every few months or as the manual suggests. |

| Can I mix different oils? | Nope! Stick to one oil type for best results! |

These tips will keep your lathe happy, and happy machines make fewer grumpy noises!

Conclusion

In summary, changing lathe oil keeps your metal lathe running smoothly. Remember to check the compound rest regularly, as it collects debris. You can improve your lathe’s performance by using clean oil. Don’t forget to read your lathe’s manual for specific tips. Let’s keep our tools in great shape for the best results! Happy machining!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Oil Changes And The Compound Rest Of A Metal Lathe:To keep a metal lathe running well, you need to change the oil regularly. This oil helps the machine work smoothly. You should check the oil level often and add more if it’s low. A clean machine will last longer and work better. Remember, it’s important to follow the instructions for your specific lathe model.

Sure! Please share the question you’d like me to answer.

What Type Of Oil Is Recommended For Lubricating The Compound Rest Of A Metal Lathe During An Oil Change?For the compound rest of a metal lathe, we should use a light machine oil. This type of oil helps everything move smoothly. Make sure the oil is clean and not too thick. Always check your lathe’s manual for any special oil recommendations.

How Often Should You Perform An Oil Change On The Compound Rest Of A Metal Lathe To Ensure Optimal Performance?You should change the oil on the compound rest of your metal lathe every 6 months. If you use it a lot, do it every 3 months. This helps keep everything running smoothly. Check the oil level often, too. Keeping it clean helps your machine last longer!

What Are The Steps Involved In Properly Changing The Oil In The Compound Rest Of A Metal Lathe?To change the oil in the compound rest of a metal lathe, follow these steps. First, turn off the lathe and unplug it for safety. Next, find the oil fill cap and unscrew it. Then, drain out the old oil carefully into a container. After that, fill it with new oil to the right level. Finally, screw the cap back on and clean up any spills.

What Signs Might Indicate That The Oil In The Compound Rest Of A Metal Lathe Needs To Be Changed?You might see dark or thick oil in the compound rest of the metal lathe. If the oil smells bad or has dirt in it, that’s a sign too. You can also check if the lathe is making strange noises, which may mean the oil isn’t working well. If you notice any of these signs, it’s time to change the oil!

How Does The Lubrication Of The Compound Rest Impact The Overall Precision And Longevity Of A Metal Lathe?Lubricating the compound rest of a metal lathe helps it move smoothly. When you add oil, it prevents parts from rubbing too much. This means cuts are cleaner and more precise. Good lubrication also keeps the lathe working longer by stopping parts from wearing out. So, putting oil in helps both how well it works and how long it lasts!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Lathe Oil Changes And The Compound Rest Of A Metal Lathe:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a metal lathe running well, you need to change the oil regularly. This oil helps the machine work smoothly. You should check the oil level often and add more if it’s low. A clean machine will last longer and work better. Remember, it’s important to follow the instructions for your specific lathe model.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please share the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Type Of Oil Is Recommended For Lubricating The Compound Rest Of A Metal Lathe During An Oil Change?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For the compound rest of a metal lathe, we should use a light machine oil. This type of oil helps everything move smoothly. Make sure the oil is clean and not too thick. Always check your lathe’s manual for any special oil recommendations.”}},{“@type”: “Question”,”name”: “How Often Should You Perform An Oil Change On The Compound Rest Of A Metal Lathe To Ensure Optimal Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should change the oil on the compound rest of your metal lathe every 6 months. If you use it a lot, do it every 3 months. This helps keep everything running smoothly. Check the oil level often, too. Keeping it clean helps your machine last longer!”}},{“@type”: “Question”,”name”: “What Are The Steps Involved In Properly Changing The Oil In The Compound Rest Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To change the oil in the compound rest of a metal lathe, follow these steps. First, turn off the lathe and unplug it for safety. Next, find the oil fill cap and unscrew it. Then, drain out the old oil carefully into a container. After that, fill it with new oil to the right level. Finally, screw the cap back on and clean up any spills.”}},{“@type”: “Question”,”name”: “What Signs Might Indicate That The Oil In The Compound Rest Of A Metal Lathe Needs To Be Changed?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You might see dark or thick oil in the compound rest of the metal lathe. If the oil smells bad or has dirt in it, that’s a sign too. You can also check if the lathe is making strange noises, which may mean the oil isn’t working well. If you notice any of these signs, it’s time to change the oil!”}},{“@type”: “Question”,”name”: “How Does The Lubrication Of The Compound Rest Impact The Overall Precision And Longevity Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lubricating the compound rest of a metal lathe helps it move smoothly. When you add oil, it prevents parts from rubbing too much. This means cuts are cleaner and more precise. Good lubrication also keeps the lathe working longer by stopping parts from wearing out. So, putting oil in helps both how well it works and how long it lasts!”}}]}