Have you ever wondered how to keep a metal lathe running smoothly? One key task is changing the lathe oil. It’s like giving your machine a refreshing drink! Regular oil changes help keep everything moving without squeaks and clanks.

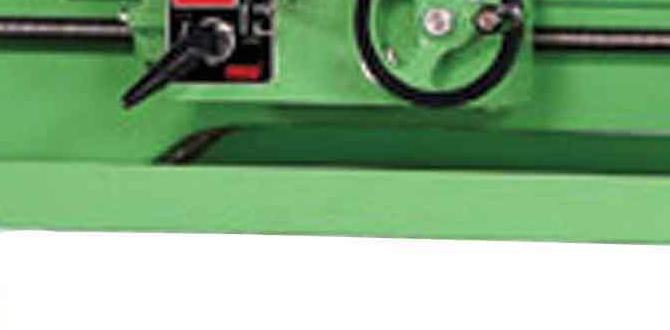

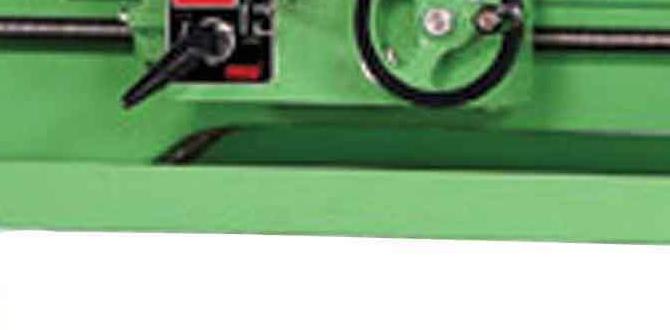

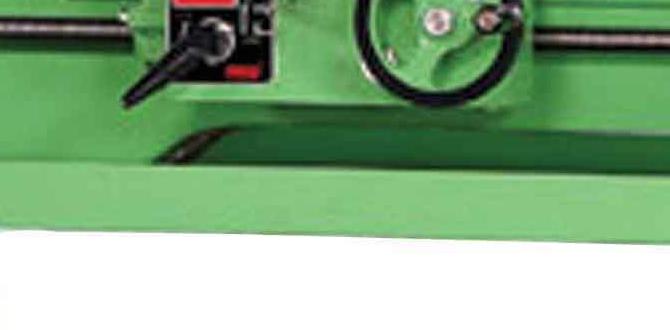

The control panel of a metal lathe helps you manage all these tasks. But do you know how it works with the oil change? A well-maintained control panel ensures your lathe operates efficiently. Imagine working with a machine that runs like new every time!

Many people overlook this simple job. Yet, a little routine maintenance goes a long way. It can extend the life of the lathe and improve its performance. So, when was the last time you checked your lathe oil? Let’s dive deeper into this essential process!

Essential Guide To Lathe Oil Change For Metal Lathe Control Panel

Lathe Oil Change for a Smooth Performance

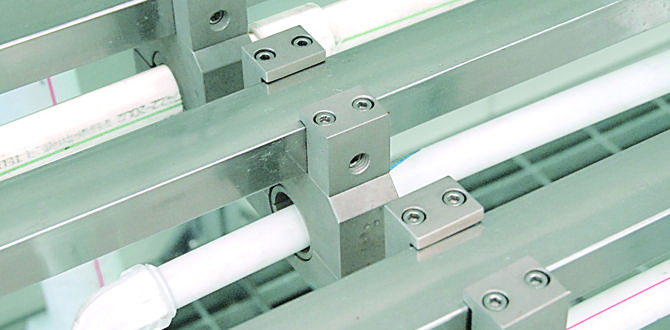

Changing lathe oil is crucial for metal lathes to run well. Regular oil changes keep the machine’s parts lubricated and free from rust. Is your lathe running smoothly? If not, it might be time for an oil change. The control panel on your lathe often has indicators that show when oil is low. Did you know that clean oil can extend your machine’s life? Keeping your lathe in top shape means better projects and less hassle.Understanding Lathe Oil and Its Importance

Definition and function of lathe oil. Impact of oil quality on lathe performance and longevity.Lathe oil is a special lubricant for metal lathes. It helps machines run smoothly and keeps parts from wearing out. When oil is high quality, the lathe cuts better and lasts longer. Using poor oil can lead to rust and damage. So, keep your lathe happy with good oil!

What is lathe oil used for?

Lathe oil keeps machines working well. It reduces friction and helps metal parts move smoothly.

Benefits of lathe oil:

- Prevents rust and corrosion.

- Reduces heat and wear.

- Improves overall machine performance.

A well-oiled lathe can perform up to 30% better than one without. Clean machines produce cleaner cuts, making your work easier!

When to Change Lathe Oil

Indicators of oil degradation. Recommended oil change intervals based on usage.Changing lathe oil is important for keeping your machine running smoothly. Here are some signs that your oil may need changing:

- Oil looks dirty or dark.

- Unusual smells coming from the oil.

- Increased machine noise during operation.

It is usually best to change oil every 50-100 hours of use. However, heavy use may need changes more often. Regular checks can help keep your lathe in top shape.

How can you tell when to change lathe oil?

Look for signs like dark or dirty oil and strange smells. These signals often mean your oil is old and needs replacing.

Tools and Materials Needed for an Oil Change

List of essential tools (e.g., wrenches, oil pump). Recommended types of lathe oil for different models.Ready to tackle an oil change? First, gather your tools. You’ll need wrenches for tight spots and an oil pump to make the job easier. Each lathe model has its favorite oil. Not every oil is the same, so choose wisely! Here’s a handy table to guide you:

| Lathe Model | Recommended Oil |

|---|---|

| Model A | SAE 20 |

| Model B | SAE 30 |

| Model C | ISO 68 |

With the right tools and oil, you’ll be zooming through that oil change like a pro. Let’s keep that lathe running smoother than a fresh jar of peanut butter!

Step-by-Step Guide to Changing Lathe Oil

Detailed procedure for oil removal. Instructions for adding new oil.Removing old lathe oil is easy. First, turn off the machine. Then, look for the drain plug under the lathe. Place a container under it. Unscrew the plug and let the oil drain out completely. After draining, clean the area around the drain hole.

Next, it’s time to add new oil. Find the oil fill plug, usually on top or the side of the machine. Pour the recommended oil into the opening. Make sure not to overfill. Secure the fill plug tightly. Your lathe is now ready to use!

How Often Should You Change Lathe Oil?

It’s best to change lathe oil every 100 hours of use. This keeps the machine running smoothly and helps avoid damage.

Common Mistakes to Avoid During Lathe Oil Change

Incorrect oil selection and its consequences. Neglecting oil filter checks.Choosing the wrong oil can harm your machine. It may lead to wear and tear, affecting performance. Always pick oil recommended for your lathe. Skipping oil filter checks is another common mistake. Dirty filters can restrict oil flow. This can damage the lathe over time. Regular checks help avoid big problems later.

What happens if you choose the wrong oil?

There may be increased wear on parts and decreased performance. Choosing the right oil is crucial for smooth operation.

Quick Tips:

- Select oil based on manufacturer guidelines.

- Check filters regularly for dirt.

- Change oil often to maintain efficiency.

Maintenance Tips for Optimal Lathe Performance

Best practices for regular maintenance. Importance of keeping the control panel clean.Regular maintenance keeps your lathe running smoothly. Check oil levels often. Clean the control panel to ensure buttons work well. Dust can cause problems. Here are some best practices:

- Inspect belts and gears regularly.

- Lubricate moving parts to prevent wear.

- Replace worn tools promptly.

- Keep the work area tidy.

A clean lathe is a happy lathe. It helps you make accurate cuts and save time!

Why is cleaning the control panel important?

Cleaning the control panel prevents dirt buildup, making the buttons easy to use. A clean panel helps you work faster and safer!

Troubleshooting Common Issues Related to Oil Change

Signs of oilrelated problems in the lathe. Solutions for addressing common issues.Spotting issues with oil changes in your lathe isn’t too hard! Look for signs like strange noises during operation or oil leaks. These can mean your oil is dirty or too low. If your lathe feels sluggish, it might be pleading for a fresh oil bath! Regular maintenance is key. For a quick fix, regularly check and change the oil. Don’t let your lathe turn into a grumpy old machine!

| Signs of Oil Issues | Simple Solutions |

|---|---|

| Strange noises | Check oil level and quality |

| Oil leaks | Tighten seals and change oil |

| Slow movement | Change oil regularly |

Environmental Considerations for Oil Disposal

Guidelines for safe disposal of used lathe oil. Ecofriendly alternatives to traditional lathe oil.Disposing of used lathe oil safely is essential for our planet. Always follow local rules for disposal to keep the earth happy. If you can’t find a place to drop it off, some areas have special recycling events for oil. Talk about a community effort! Consider using eco-friendly alternatives, too. They’re good for your machine and Mother Nature. Who knew being responsible could be this easy?

| Type | Disposal Method | Eco-Friendly Alternative |

|---|---|---|

| Used Lathe Oil | Check with local waste facility | Vegetable-Based Oils |

| Other Oil Waste | Special Recycling Locations | Synthetic Oils |

Conclusion

In summary, changing lathe oil is vital for keeping your metal lathe running smoothly. The control panel allows you to manage the settings easily. Regular maintenance will extend the life of your machine. Always check oil levels before starting work. You can find more tips online to help you with lathe care. Let’s keep our tools in great shape!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Oil Change And The Metal Lathe Control Panel:Sure! When changing the oil in a lathe, make sure to turn off the machine first. You can usually find the oil fill point on the side of the lathe. Use a clean rag to wipe up any spills. Check the control panel to see if there are any warning lights. If there are, make sure to check the manual for help.

Sure! Please go ahead and ask your question, and I’ll provide a simple answer for you.

What Are The Recommended Types Of Oil For Maintaining A Metal Lathe, And How Often Should Oil Changes Be Performed?For a metal lathe, you should use machine oil or way oil. These oils keep the parts moving smoothly. We should change the oil every few months or when it looks dirty. Always check the oil level to keep your lathe happy!

How Can I Identify Signs That My Metal Lathe Needs An Oil Change?You can tell your metal lathe needs an oil change if you notice strange noises. If the machine feels hot or sticky, that’s another sign. Check the oil color too; it should be clear or light brown. Dark or dirty oil means it’s time for a change. Always remember to check the oil level regularly!

What Specific Procedures Should Be Followed To Safely Change The Oil In A Metal Lathe Without Damaging The Machine?To safely change the oil in a metal lathe, first, turn off the machine and unplug it. Next, let the old oil cool down if it was running. Then, find the oil drain plug and put a container under it to catch the old oil. Remove the plug and let the oil drain out. After that, you can add new oil through the fill hole, making sure to use the right type. Finally, replace the drain plug and clean up any spills.

How Does The Control Panel Of A Metal Lathe Monitor And Indicate Oil Levels Or Maintenance Schedules?The control panel of a metal lathe shows you the oil levels with lights or gauges. If the oil is low, a light turns on to remind you to add more. It can also have a timer that tells you when to check or change the oil. This way, you keep the machine running smoothly and safely.

What Role Does The Lubrication System Play In The Overall Performance And Longevity Of A Metal Lathe?The lubrication system in a metal lathe keeps moving parts slippery and smooth. This helps the machine work better and faster. When parts are well-lubricated, they don’t wear down as quickly. This means your lathe can last longer and do a better job. So, taking care of the lubrication helps everyone!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Oil Change And The Metal Lathe Control Panel:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! When changing the oil in a lathe, make sure to turn off the machine first. You can usually find the oil fill point on the side of the lathe. Use a clean rag to wipe up any spills. Check the control panel to see if there are any warning lights. If there are, make sure to check the manual for help.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please go ahead and ask your question, and I’ll provide a simple answer for you.”}},{“@type”: “Question”,”name”: “What Are The Recommended Types Of Oil For Maintaining A Metal Lathe, And How Often Should Oil Changes Be Performed?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For a metal lathe, you should use machine oil or way oil. These oils keep the parts moving smoothly. We should change the oil every few months or when it looks dirty. Always check the oil level to keep your lathe happy!”}},{“@type”: “Question”,”name”: “How Can I Identify Signs That My Metal Lathe Needs An Oil Change?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can tell your metal lathe needs an oil change if you notice strange noises. If the machine feels hot or sticky, that’s another sign. Check the oil color too; it should be clear or light brown. Dark or dirty oil means it’s time for a change. Always remember to check the oil level regularly!”}},{“@type”: “Question”,”name”: “What Specific Procedures Should Be Followed To Safely Change The Oil In A Metal Lathe Without Damaging The Machine?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To safely change the oil in a metal lathe, first, turn off the machine and unplug it. Next, let the old oil cool down if it was running. Then, find the oil drain plug and put a container under it to catch the old oil. Remove the plug and let the oil drain out. After that, you can add new oil through the fill hole, making sure to use the right type. Finally, replace the drain plug and clean up any spills.”}},{“@type”: “Question”,”name”: “How Does The Control Panel Of A Metal Lathe Monitor And Indicate Oil Levels Or Maintenance Schedules?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The control panel of a metal lathe shows you the oil levels with lights or gauges. If the oil is low, a light turns on to remind you to add more. It can also have a timer that tells you when to check or change the oil. This way, you keep the machine running smoothly and safely.”}},{“@type”: “Question”,”name”: “What Role Does The Lubrication System Play In The Overall Performance And Longevity Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The lubrication system in a metal lathe keeps moving parts slippery and smooth. This helps the machine work better and faster. When parts are well-lubricated, they don’t wear down as quickly. This means your lathe can last longer and do a better job. So, taking care of the lubrication helps everyone!”}}]}