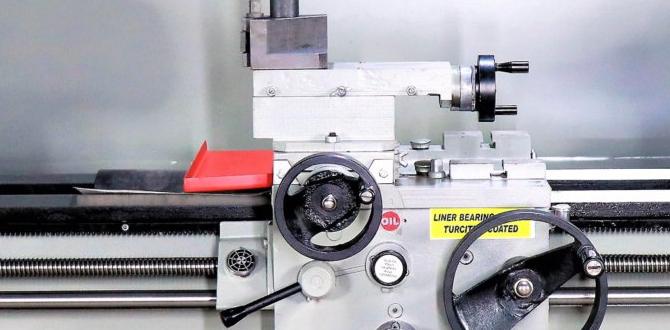

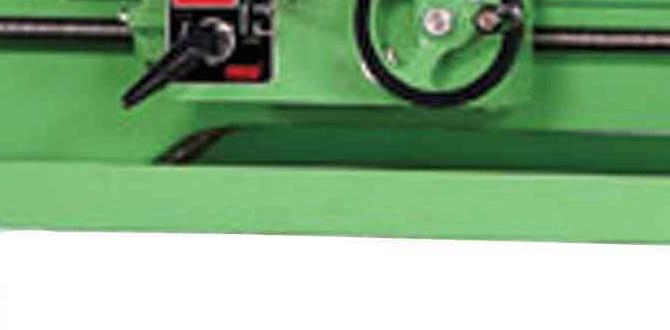

Have you ever wondered why regular maintenance matters for your metal lathe? One important task is the lathe oil change. Just like changing oil in a car, your metal lathe needs clean oil to run smoothly. But did you know that it can also protect the machine from damage?

Picture this: you’re ready to start a new project, but your lathe doesn’t work right. It can be frustrating! Keeping things like the controller board in good shape means checking and changing the lathe oil regularly.

Many people don’t realize how simple it is. With just a few steps, you can ensure your metal lathe runs well for a long time. Read on to discover how to change lathe oil and why it matters!

Lathe Oil Change For Metal Lathe Controller Board Maintenance — When It Comes To Ensuring The Longevity And Performance Of Your Metal Lathe, Routine Maintenance Is Essential. One Critical Aspect Of This Upkeep Is Performing A Lathe Oil Change, Particularly For Machinery That Is Integrated With A Controller Board. Proper Lubrication Is Vital Not Only For The Mechanical Parts But Also For The Electronic Components To Function Efficiently. Understanding Lathe Oil Importance Lathe Oil Serves Several Purposes In Metalworking Equipment, Providing Lubrication, Reducing Friction, And Preventing Wear And Tear. When Using A Metal Lathe Equipped With A Controller Board, The Need For Proper Lubrication Escalates, As Control Components Can Be Sensitive To Dust And Dry Operation. Regular Oil Changes Can Mitigate These Issues, Ensuring Smooth Operation And Prolonging Your Machine’S Lifespan. When To Change The Oil It’S Important To Establish A Routine For Changing The Oil Based On The Frequency Of Use, The Manufacturer’S Recommendations, And The Type Of Projects You Engage In. A Good Rule Of Thumb Is To Inspect The Oil Every 50-100 Hours Of Operation Or After Completing Significant Projects. Steps For A Successful Lathe Oil Change 1. **Turn Off And Unplug Your Lathe**: Safety Is Paramount, So Ensure Your Machine Is Powered Down And Disconnected To Prevent Any Accidents. 2. **Remove The Oil Drain Plug**: Locate And Carefully Remove The Drain Plug To Allow The Old Oil To Flow Out. Be Cautious To Collect The Oil In A Suitable Container. 3. **Clean The Reservoir**: While The Old Oil Is Draining, Take The Opportunity To Clean The Oil Reservoir And Surrounding Areas, Removing Any Metal Shavings Or Debris. 4. **Replace The Oil Filter**: If Your Lathe Model Uses A Filter, Make Sure To Change It According To The Manufacturer’S Guidelines To Ensure Optimal Performance. 5. **Add New Lathe Oil**: Once The Old Oil Is Completely Drained And The Reservoir Is Clean, Pour In Fresh Lathe Oil, Ensuring Not To Overfill. 6. **Check The Controller Board Compatibility**: Ensure That The New Oil You Are Using Is Compatible With The Electronic Components Of The Metal Lathe Controller Board. 7. **Replace The Drain Plug**: Once The Oil Change Is Complete, Securely Fasten The Drain Plug Back Onto The Reservoir. 8. **Power Up And Test**: After Ensuring Everything Is In Place, Reconnect The Power Supply And Do A Test Run. Listen For Any Unusual Noises And Check For Leaks. Conclusion Regularly Changing The Lathe Oil In Your Metal Lathe Is An Essential Part Of Maintaining Both The Mechanical And Electronic Aspects Of The Machine, Including The Controller Board. By Adhering To A Consistent Maintenance Routine, You Can Ensure Your Metal Lathe Operates Smoothly And Efficiently For Years To Come.

Lathe Oil Change and Controller Board Insights

Changing lathe oil is essential for keeping your metal lathe running smoothly. Over time, the oil collects dirt and particles, which can harm your machine. Regular oil changes help avoid costly repairs. Have you ever wondered how a controller board impacts your lathe’s performance? A well-maintained controller board ensures correct operations and enhances precision. Fun fact: a simple oil change can extend the life of your lathe significantly, making it a small step for big benefits!Understanding Lathe Oil and Its Importance

Definition and purpose of lathe oil. Importance of regular oil change for performance and longevity.Lathe oil is like a superhero for your metal lathe. It keeps everything running smoothly and helps parts move without squeaking like a rusty door. Regular oil changes are important because they boost the lathe’s performance and help it last longer. Think of it as giving your lathe a little spa day! If you don’t change the oil, it can get dirty and thick, making things stick. So, remember to show your lathe some love with fresh oil!

| Purpose of Lathe Oil | Importance of Regular Change |

|---|---|

| Lubrication – Reduces friction | Performance – Keeps machinery running smoothly |

| Cooling – Prevents overheating | Longevity – Helps your lathe last longer |

| Rust prevention – Protects metal parts | Efficiency – Avoids costly repairs |

Signs Your Metal Lathe Needs an Oil Change

Indicators of low oil levels and contamination. Consequences of neglecting oil changes.Is your metal lathe feeling a bit sluggish? Look out for signs that it needs an oil change! Low oil levels can lead to squeaks and groans, which sound like your lathe is telling you a secret. Dark or cloudy oil is a sure sign of contamination—yikes! Ignoring these signs can lead to more than just a noisy machine. It can cause serious damage and cost you big bucks in repairs. Remember, a happy lathe is an oiled lathe!

| Sign | Description |

|---|---|

| Low Oil Level | Make sure the oil is visible and not hiding! |

| Cloudy Oil | If it looks like soup, it’s time to change! |

Step-by-Step Guide to Changing Lathe Oil

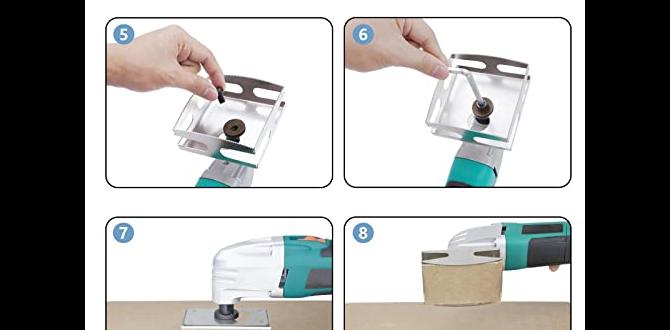

Tools and materials needed for the oil change. Detailed process of draining old oil and adding new oil.Changing lathe oil is easier than learning to ride a bike! First, gather your tools: an oil pan, wrench, and some fresh lathe oil. These items will make your job smoother than a buttered frying pan.

Begin by draining the old oil. Place the oil pan under the lathe, unscrew the drain plug, and let the gunk flow out. It’s like emptying your trash—always better when it’s clean! After that, replace the drain plug securely.

Next, add new oil. Use a funnel to avoid a slippery mess. Pour until it reaches the recommended level. And voilà! You’re done. Your lathe is ready for action, like a superhero with a shiny new cape!

| Tools & Materials | Description |

|---|---|

| Oil Pan | To catch the old oil. |

| Wrench | To unscrew the drain plug. |

| Fresh Lathe Oil | Your lathe’s favorite drink. |

Maintenance Tips for Your Metal Lathe Controller Board

Regular inspection and cleaning tips. Best practices for prolonging the lifespan of the controller board.Keeping your metal lathe controller board in tip-top shape is easier than you think! Regular inspections can spot trouble before it starts. Check for dust or debris. A quick wipe can do wonders. To keep it running smoothly, try this: Limit exposure to heat and moisture. Board longevity is one goal, and a happy lathe is another! Remember, if it looks dusty, it’s just waiting for a good cleaning. Here’s a quick table for your daily maintenance schedule:

| Task | Frequency |

|---|---|

| Inspect for dust | Every week |

| Clean with a soft cloth | Every month |

| Check cables and connections | Every three months |

Finally, follow these simple tips, and soon your lathe will be the envy of the shop! Who knew maintenance could be so much fun? Let’s keep those controllers dancing!

Common Mistakes to Avoid During an Oil Change

Frequent errors made by novice users. Best practices to ensure a successful oil change.Many new users make simple mistakes during an oil change. One common error is forgetting to clean the area before starting. Dirt can mess up the oil flow, kind of like a cat and a bathtub! Another mistake is not allowing the old oil to fully drain. This can lead to mixing fresh and used oils, which is a big no-no.

To avoid these blunders, always prepare your tools ahead of time. Check for leaks after the change to ensure your metal lathe runs smoothly. Remember, oil changes should be done regularly for the best performance! And hey, no one likes a messy workbench, right?

| Common Mistakes | Best Practices |

|---|---|

| Not cleaning before starting | Clean the area first! |

| Not letting oil fully drain | Wait for it all to come out |

| Ignoring leaks | Check for leaks after the change |

Recommended Oil Change Frequency for Metal Lathes

Factors influencing oil change frequency. General guidelines based on usage and environment.Oil change frequency for a metal lathe varies. Several factors affect how often you should change the oil. These include how much you use the lathe and the conditions in your workshop. For example, working in a dusty area might require more frequent oil changes.

Here are some general guidelines:

- If used daily, change oil every 50 hours.

- For weekly use, consider changing it every month.

- In a clean environment, you may go longer without changing it.

Regular checks help keep the lathe in good shape. Remember, a well-oiled machine runs smoothly!

How often should I change lathe oil?

Change lathe oil every 50 hours of use or once a month for less frequent use.

Frequently Asked Questions about Lathe Oil Changes

Common queries regarding oil types and oil change processes. Troubleshooting oilrelated issues in metal lathes.Many people have questions about changing oil in lathes. It’s important to use the right oil type. You should check your machine’s manual for specific recommendations. This can help avoid problems down the road. When changing oil, make sure to clean any filters. This keeps your lathe running smoothly.

What type of oil should I use for my lathe?

Always choose non-detergent oil for your lathe. Check your machine’s manual for the correct viscosity. A common choice is 68-grade oil.

How do I know when to change the oil?

Change the oil after every 50 hours of use. If the oil looks dirty or has dark spots, it’s time to change it.

What should I do if I see a leak?

- Check the oil seals for damage.

- Tighten any loose fittings.

- Replace worn parts as needed.

Keeping your lathe oiled properly can make a big difference. It can even extend the machine’s life. Take care of your lathe, and it will take care of you!

Conclusion

In summary, changing lathe oil is vital for keeping your metal lathe in great shape. A good oil change helps your lathe run smoothly and last longer. Understanding your controller board makes this task easier. We encourage you to check your lathe’s oil regularly and read more about maintenance tips. Your lathe will thank you for it!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Oil Change For A Metal Lathe Controller Board:1. Why do we need to change the oil in a metal lathe? We change the oil to keep the machine running smoothly. Fresh oil helps reduce friction and prevents rust. 2. How often should you change the oil? You should check the oil every month. Change it more often if you use the lathe a lot. 3. What happens if you don’t change the oil? If we don’t change the oil, it can get dirty. This can make the lathe work poorly and wear out faster. 4. How do you change the oil? To change the oil, first, turn off the lathe. Then, drain the old oil and fill it with new oil. 5. Where can you buy lathe oil? You can buy lathe oil at hardware stores or online. Make sure to choose the right kind for your lathe.

Sure! Please provide the question you’d like me to answer, and I’ll do my best to help you!

What Type Of Oil Is Recommended For A Metal Lathe, And How Often Should It Be Changed?For a metal lathe, you should use light machine oil or specialized lathe oil. This oil helps the machine run smoothly and prevents rust. You should change the oil every few months or when it looks dirty. Keeping the oil fresh helps the lathe work better and last longer.

How Do You Safely Drain And Replace The Oil In A Metal Lathe To Ensure The Longevity Of The Machine?To safely drain and replace the oil in a metal lathe, first, turn off the machine. Next, let it cool down. Place a container under the oil drain plug to catch the old oil. Unscrew the plug and let the oil flow out completely. Once it’s empty, screw the plug back in and fill the machine with fresh oil. Make sure to use the type of oil the lathe needs, so it works well and lasts longer.

What Are The Common Signs That Indicate It’S Time To Change The Lathe Oil In A Metal Lathe?You can tell it’s time to change the lathe oil when it looks dirty or dark. If you notice the machine making strange noises, that’s another sign. Also, if the oil smells bad, you should replace it. Finally, check the oil level; if it’s low, you need to add or change it.

How Does The Condition Of The Lathe Oil Affect The Performance And Accuracy Of The Metal Lathe?Lathe oil helps your metal lathe run smoothly. If the oil is dirty or old, it can cause problems. You might notice the lathe making more noise or not cutting the metal right. Good oil keeps everything moving well, which means better shapes and sizes in your work! Always check and change the oil to keep your lathe happy.

Are There Specific Maintenance Procedures For The Controller Board That Should Be Followed During An Oil Change On A Metal Lathe?Yes, you need to be careful with the controller board during an oil change. First, turn off the machine and unplug it. This keeps you safe. Next, check for dust and dirt on the board and gently clean it. Lastly, make sure to avoid getting any oil on the controller board. This will help it work properly.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Oil Change For A Metal Lathe Controller Board:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “1. Why do we need to change the oil in a metal lathe? We change the oil to keep the machine running smoothly. Fresh oil helps reduce friction and prevents rust. 2. How often should you change the oil? You should check the oil every month. Change it more often if you use the lathe a lot. 3. What happens if you don’t change the oil? If we don’t change the oil, it can get dirty. This can make the lathe work poorly and wear out faster. 4. How do you change the oil? To change the oil, first, turn off the lathe. Then, drain the old oil and fill it with new oil. 5. Where can you buy lathe oil? You can buy lathe oil at hardware stores or online. Make sure to choose the right kind for your lathe.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer, and I’ll do my best to help you!”}},{“@type”: “Question”,”name”: “What Type Of Oil Is Recommended For A Metal Lathe, And How Often Should It Be Changed?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For a metal lathe, you should use light machine oil or specialized lathe oil. This oil helps the machine run smoothly and prevents rust. You should change the oil every few months or when it looks dirty. Keeping the oil fresh helps the lathe work better and last longer.”}},{“@type”: “Question”,”name”: “How Do You Safely Drain And Replace The Oil In A Metal Lathe To Ensure The Longevity Of The Machine?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To safely drain and replace the oil in a metal lathe, first, turn off the machine. Next, let it cool down. Place a container under the oil drain plug to catch the old oil. Unscrew the plug and let the oil flow out completely. Once it’s empty, screw the plug back in and fill the machine with fresh oil. Make sure to use the type of oil the lathe needs, so it works well and lasts longer.”}},{“@type”: “Question”,”name”: “What Are The Common Signs That Indicate It’S Time To Change The Lathe Oil In A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can tell it’s time to change the lathe oil when it looks dirty or dark. If you notice the machine making strange noises, that’s another sign. Also, if the oil smells bad, you should replace it. Finally, check the oil level; if it’s low, you need to add or change it.”}},{“@type”: “Question”,”name”: “How Does The Condition Of The Lathe Oil Affect The Performance And Accuracy Of The Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe oil helps your metal lathe run smoothly. If the oil is dirty or old, it can cause problems. You might notice the lathe making more noise or not cutting the metal right. Good oil keeps everything moving well, which means better shapes and sizes in your work! Always check and change the oil to keep your lathe happy.”}},{“@type”: “Question”,”name”: “Are There Specific Maintenance Procedures For The Controller Board That Should Be Followed During An Oil Change On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, you need to be careful with the controller board during an oil change. First, turn off the machine and unplug it. This keeps you safe. Next, check for dust and dirt on the board and gently clean it. Lastly, make sure to avoid getting any oil on the controller board. This will help it work properly.”}}]}