Have you ever wondered how a metal lathe keeps running smoothly? Many people don’t realize that a simple lathe oil change can make a big difference. It’s like giving your car an oil change; it needs the right care to run well.

Imagine a metal lathe in a busy workshop. Every day, it spins and cuts metal, shaping it into useful parts. But what happens when the oil gets old? Just like your bike needs grease on its wheels, a lathe needs clean oil in its drive system.

Fun fact: Many experts agree that regular oil changes can extend the life of your lathe. It not only improves performance but also helps prevent costly repairs. So, why not learn about how to properly change the oil in your lathe and keep it in top shape?

Essential Guide To Lathe Oil Change For Metal Lathe Drive System

Lathe Oil Change for Metal Lathe Drive System

Changing lathe oil is essential for keeping your metal lathe drive system running smoothly. Oil lubricates the moving parts and reduces friction. Have you ever heard a loud noise while working? That might mean your lathe oil needs attention. Regular oil changes help prevent damage and extend the life of your machine. Did you know that fresh oil can improve performance? Make oil changes part of your routine to ensure your lathe always operates at its best.

Understanding the Importance of Lathe Oil

Discuss the role of oil in the metal lathe drive system. Explain how proper lubrication affects performance and longevity.

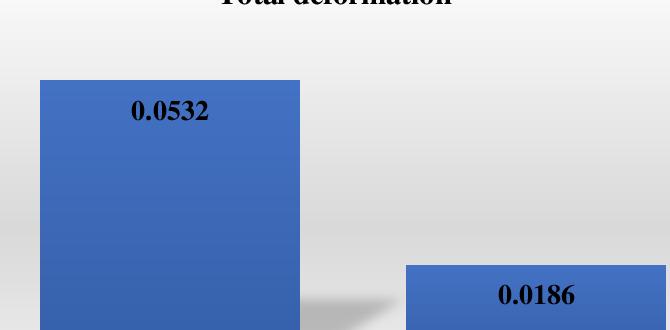

Oil in a metal lathe is like a superhero sidekick. It helps everything run smoothly! Proper lubrication means less friction and less wear. This keeps the machine happy and working longer. If the oil runs low, parts can get cranky and wear out faster. In fact, machines with good oil can last up to 50% longer! So, keep that lathe oiled like you would keep your bike tires pumped.

| Benefits of Proper Lubrication | Consequences of Low Oil |

|---|---|

| Increased performance | Faster wear and tear |

| Longer machine life | Potential breakdowns |

| Smoother operation | Louder noises |

When to Change Lathe Oil

Indicators that it’s time for an oil change. Recommended maintenance schedule for different lathe models.

It’s important to know when to change lathe oil. Look for signs like strange noises or slow movements. These could mean the oil is dirty. For regular upkeep, checking every 50-100 hours is wise. Here’s a quick guide:

- Entry-Level Lathe: Every 50 hours

- Mid-Range Lathe: Every 80 hours

- Professional Lathe: Every 100 hours

Regular oil changes help your machine run smoothly and last longer.

How often should I change my lathe oil?

Change your lathe oil every 50 to 100 hours depending on your model. This keeps the lathe working well.

Step-by-Step Guide to Changing Lathe Oil

Detailed instructions on preparing the lathe for an oil change. Stepbystep process for draining and replacing oil.

Before changing the lathe oil, prepare the machine. Start by turning off the power. Next, make sure the lathe is cool. Then, gather your tools, like an oil pan and a wrench. Following this, locate the oil drain plug. Carefully follow these steps:

- Unscrew the drain plug.

- Let the old oil drain completely.

- Replace the drain plug snugly.

- Fill the lathe with fresh oil.Check the manual for the right type!

- Run the lathe briefly to circulate the new oil.

How often should you change lathe oil?

Change lathe oil every 50 hours of use. Regular changes help keep the machine in great shape.

Common Mistakes to Avoid During Oil Changes

List frequent errors made during the oil change process. Tips for preventing crosscontamination and using incorrect oils.

Changing oil in a metal lathe can be tricky. Here are some common mistakes to avoid:

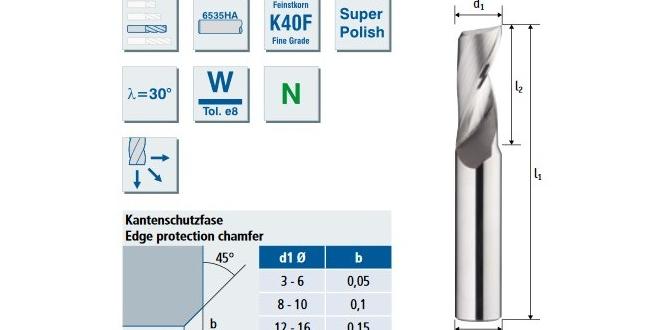

- Using the wrong oil: Always check your lathe’s manual for the correct type.

- Mixing oils: Different oils can react badly together. Empty the tank before adding new oil.

- Not cleaning the area: Dirt can mix with oil and cause damage. Always wipe surfaces before changing.

By avoiding these errors, your lathe will stay in top shape!

What are tips to prevent cross-contamination during oil changes?

To prevent cross-contamination, keep oils stored separately and clearly labeled. Always use clean tools for the oil change. This helps your lathe perform well.

Signs of Oil-Related Issues in Lathe Performance

Symptoms indicating oil problems affecting lathe operations. Troubleshooting tips for resolving oilrelated issues.

Ever noticed your lathe acting a bit cranky? Signs like strange noises, poor cutting quality, or excessive heat can mean oil problems. These issues might signal it’s time for an oil change. Check the oil level—low oil can be a sneaky culprit. Also, if your lathe seems to have a mind of its own, it might be time to troubleshoot. Here’s a quick table to help:

| Symptom | Possible Issue | Troubleshooting Tip |

|---|---|---|

| Noisy Operation | Low Oil | Check oil level and refill. |

| Poor Cutting | Dirty Oil | Change oil and clean filters. |

| Excessive Heat | Insufficient Lubrication | Ensure proper oil type is used. |

Keep an eye on these signs. A happy lathe means more fun and less stress in the workshop!

Benefits of Regular Oil Maintenance for Metal Lathes

Explanation of longterm advantages including efficiency and cost savings. Discuss how regular oil changes extend tool life and maintain precision.

Keeping up with regular oil changes helps metal lathes work better. This means you save money in the long run. Good oil keeps parts running smoothly and helps them last longer. With the right care, your tools stay sharp and precise.

- Increased efficiency for faster work.

- Lower repair costs over time.

- Longer tool life, meaning less replacement.

Regular maintenance is like a magic potion for your lathes. Treat them well, and they’ll treat you well back!

Why is regular oil change important for metal lathes?

Regular oil changes keep your lathe precise, increase efficiency, and lower costs. Without it, parts wear out faster.

FAQs About Lathe Oil Change

Answers to common questions regarding oil types, frequency of changes, and maintenance practices. Clarifying misconceptions about lathe lubrication.

Many people have questions about lathe oil change. Here are some common ones:

What type of oil should I use?

Use a high-quality machine oil. It will help your lathe run smoothly.

How often should I change the oil?

Change the oil every 50 hours of use. Regular changes keep your lathe in great shape.

What are common mistakes?

- Using the wrong oil type

- Not changing oil often enough

- Ignoring signs of wear

Always follow the manufacturer’s recommendations for best results!

Conclusion

In conclusion, changing the lathe oil in your metal lathe drive system is crucial for smooth operation. Regular oil changes help prevent wear and tear. Always check the manufacturer’s guidelines for the right type of oil. Now, you can keep your lathe running well and extend its life. For more tips, consider reading more about lathe maintenance!

FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Oil Change In A Metal Lathe Drive System:

Sure! When you change the oil in a metal lathe, you help it work better. First, you need to turn off the lathe and let it cool down. Then, you can find the oil drain plug and open it. Be careful to catch the old oil in a container. Finally, add new oil to the lathe and close everything up. Now, your lathe is ready to work smoothly!

Sure! Please share the question you’d like me to answer.

What Type Of Oil Is Recommended For Lubricating The Drive System Of A Metal Lathe?

You should use a light machine oil to lubricate the drive system of a metal lathe. This oil helps the parts move smoothly. It keeps the lathe working well and prevents rust. Always check the machine’s manual for the best oil type.

How Often Should The Oil In A Metal Lathe’S Drive System Be Changed To Ensure Optimal Performance?

You should change the oil in a metal lathe’s drive system every few months. The exact time depends on how much you use the lathe. If you use it often, change the oil every month. Always check the oil color; if it looks dirty, it’s time for a change! Regular oil changes keep the machine working well.

What Are The Signs That Indicate It’S Time To Change The Oil In A Metal Lathe’S Drive System?

You should change the oil in a metal lathe’s drive system when you see dark or dirty oil. If you notice strange noises while it runs, that’s another sign. If the machine feels hot to the touch, it might need new oil. Also, if you see metal shavings in the oil, it’s time for a change. Keeping oil fresh helps the machine work better!

What Is The Proper Procedure For Draining And Replacing The Oil In The Drive System Of A Metal Lathe?

First, make sure the lathe is turned off and cool. Then, find the oil drain plug and unscrew it to let the old oil flow out into a container. Once the oil stops dripping, screw the plug back in tightly. Next, find the fill hole and pour in new oil using a funnel. Finally, check the oil level and make sure it’s just right.

Are There Specific Precautions Or Maintenance Tips To Consider When Changing The Oil In A Metal Lathe’S Drive System?

When changing the oil in a metal lathe’s drive system, you should be careful. First, always turn off the machine and unplug it. Next, wear gloves to protect your hands. Make sure you use the right oil for your lathe. Finally, clean any spills right away to keep the area safe.