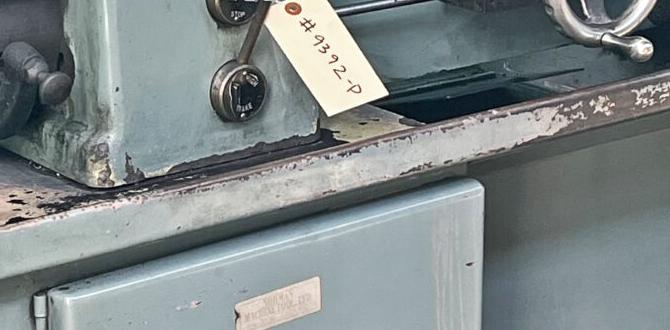

Essential Guide: Lathe Oil Change And Metal Lathe Foot Brake

Lathe Oil Change and Foot Brake Tips

Changing lathe oil is vital for keeping your metal lathe in top shape. Proper lubrication lowers friction and extends the tool’s life. Did you know that clean oil can enhance machining accuracy? When it comes to the foot brake, always ensure it functions well for safety. A sticky brake can lead to accidents. Remember, regular maintenance keeps your equipment running smoothly and your workspace safe. Why wait? Take care of your lathe today!

Understanding Lathe Oil: Importance and Types

Explain the role of lathe oil in maintaining metal lathes.. Discuss different types of lathe oils and their specific applications..

Lathe oil is essential for keeping metal lathes working well. It helps reduce friction and wear on the machine parts. When you use lathe oil, it protects the lathe from overheating and rust. There are different types of lathe oils available. Each type serves a specific purpose:

- Mineral oil: Good for general use.

- Synthetic oil: Offers better protection and lasts longer.

- Cutting oil: Used for cutting metal; it cools and lubricates.

Choosing the right oil keeps your lathe in top shape. This way, it can work efficiently for years.

What is the purpose of lathe oil?

The purpose of lathe oil is to lubricate and protect the machine parts from friction, heat, and corrosion.

When to Change Lathe Oil

Identify signs indicating the need for an oil change.. Recommend maintenance schedules based on usage frequency..

Noticing changes in your machine’s performance? It might be time for an oil change. Look out for these signs:

- Unusual noises from the lathe.

- Your workpiece looks rough or uneven.

- Oil appears dark and dirty.

Also, consider how often you use your lathe. If you use it daily, changing oil every month is best. For lighter use, every few months may suffice. Regular oil checks keep your machine running smoothly.

How often should lathe oil be changed?

Change lathe oil every 30 days for daily use and every 3-4 months for occasional use.

Tools and Materials Needed for Lathe Oil Change

List essential tools for changing lathe oil.. Describe the types of oil and additives required..

Before you change the oil in your lathe, gather some tools and materials. You will need:

- Wrenches

- Screwdrivers

- Oil catch pan

- Clean rags

- Funnel

For the oil itself, you might use:

- Lathe oil or machine oil

- Additives for better performance

Choose high-quality oil to help your lathe run smoothly.

What kind of oil should be used for a lathe?

The best choice is high-quality lathe or machine oil. It keeps the lathe working well and helps prevent rust.

Step-by-Step Guide to Changing Lathe Oil

Provide a detailed procedure for draining old oil and adding new oil.. Highlight safety precautions to consider during the process..

Changing lathe oil is simple. First, turn off the machine and let it cool. This is important for safety. Then, find the oil drain plug and place a container underneath. Open the plug and let the old oil drain out. Next, replace the plug and refill with fresh oil through the fill port. Make sure to use the right type of oil. Always clean any spills, and remember to wear gloves and goggles for protection.

How do I know when to change the oil?

Check the oil color and consistency regularly. If it looks dark or dirty, it’s time to change it. Also, follow the manufacturer’s guidelines for maintenance schedules.

Safety Tips:

- Always turn off power before starting.

- Let the machine cool down.

- Wear safety gloves and goggles.

- Have a first aid kit nearby.

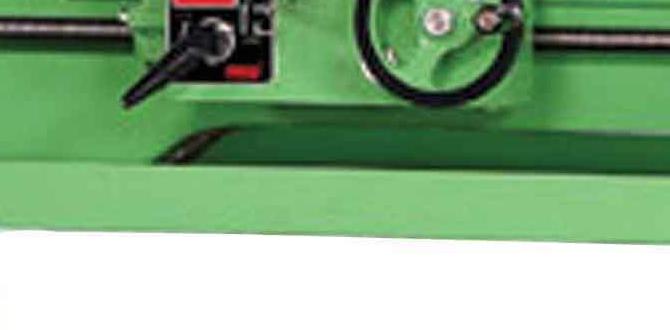

Maintaining the Foot Brake System on Metal Lathes

Outline the function of the foot brake and its significance for safety.. Discuss common issues with foot brakes and their impact on operations..

The foot brake on a metal lathe is very important. It helps stop the machine quickly. This feature keeps the operator safe. Without a working foot brake, serious accidents can happen. Common problems include:

- Brake not responding

- Worn-out parts

- Loose connections

These issues can slow down work and may damage the lathe. Regular checks and quick fixes ensure smooth operations.

What are the benefits of a foot brake?

The foot brake improves safety and control during machining. It enhances precision and reduces risk. Quick stopping can prevent injuries and machine damage.

Steps for Foot Brake Inspection and Maintenance

Provide stepbystep instructions for inspecting the foot brake system.. Recommend repair or replacement procedures for faulty components..

First, check the foot brake for any visible damage. Look for cracks or wear. Squat down and give it a gentle press. Does it feel sticky? It should move smoothly, like a well-oiled slide! If it feels funny, jot it down.

Next, inspect the springs and cables. If they look sad or stretched, it’s time for a change. Don’t let your foot brake end up like that old soda can in the back of your fridge!

If anything seems broken, consider repairing or replacing those parts. Keeping your foot brake in tip-top shape will help ensure your lathe works smoothly.

| Action | Recommendation |

|---|---|

| Check for damage | Replace if cracked |

| Inspect springs | Replace if stretched |

| Test movement | Repair or replace as needed |

Remember, a well-maintained brake can save you a lot of trouble later—like avoiding a runaway lathe situation! Not the thrill ride you want!

Best Practices for Lathe Maintenance

Share top tips for prolonging the life of a metal lathe.. Discuss the importance of regular inspections and maintenance schedules..

To keep your metal lathe running smoothly, a little love goes a long way! First, check it often. Regular inspections help catch problems before they start getting out of hand. Think of it as giving your lathe a health check-up. Next, stick to a maintenance schedule. If it sounds fancy, make it fun! Maybe mark your calendar with “Lathe Spa Day.” This way, you can clean the parts, change the oil, and even check that all the screws are tight. Trust us; a happy lathe makes for easier work.

| Tip | Action |

|---|---|

| Inspect Regularly | Check parts for wear and tear. |

| Change Oil | Keep it clean and lubricated. |

| Schedule Maintenance | Set regular days for checking. |

Remember, maintaining your lathe means it can work at its best. After all, nobody wants a grumpy machine, right?

Common Mistakes to Avoid During Oil Change and Brake Maintenance

List pitfalls often encountered during oil changes and brake maintenance.. Provide solutions and recommendations for best practices..

Many people make mistakes during oil changes and brake maintenance. Here are some common traps to avoid:

- Skipping the old oil removal.

- Not checking for leaks after maintenance.

- Using the wrong type of oil.

- Neglecting the foot brake adjustment.

To do it right, always:

- Follow the manufacturer’s guidelines.

- Use quality oil and parts.

- Inspect the brakes regularly.

These steps can help keep your metal lathe running smoothly.

What are the best practices for oil change and brake maintenance?

Always consult your machine manual, use the right tools, and work in a clean area. This makes a big difference in keeping everything working well.

Conclusion

In summary, changing lathe oil is essential for your metal lathe’s performance. A clean foot brake ensures safe operation. You should regularly check both to keep your lathe in great shape. Remember, regular maintenance helps your tools last longer and work better. For more tips, check out helpful guides or videos on lathe care. Let’s keep our machines running smoothly!

FAQs

What Type Of Oil Is Recommended For Changing The Lathe Oil In A Metal Lathe?

You should use a light machine oil for changing the oil in a metal lathe. This type of oil helps the machine run smoothly. Look for oils that are designed for metalworking or general machine use. Always check the label to make sure it’s right for your lathe.

How Often Should The Lathe Oil Be Changed To Ensure Optimal Performance Of The Metal Lathe?

You should change the lathe oil every 3 to 6 months. This helps keep your metal lathe running smoothly. If you use it a lot, change it more often. Always check for dirt or dust in the oil, too!

What Steps Should Be Taken To Safely Change The Lathe Oil In A Metal Lathe?

To change the lathe oil safely, first, turn off the machine and unplug it. Then, let the lathe cool down if it was used recently. Next, locate the oil drain plug and place a clean container under it. Open the plug to let the old oil drain out completely. Finally, refill with fresh lathe oil, close the plug, and clean any spills.

How Does The Functionality Of The Foot Brake In A Metal Lathe Affect The Oil Change Process?

The foot brake on a metal lathe stops the machine quickly. When you change the oil, you want the lathe to be completely still. If the foot brake works well, it helps stop the lathe fast and safely. This makes it easier to drain old oil and add new oil. So, a good foot brake helps keep everything running smoothly during the oil change.

Are There Specific Maintenance Tips For The Foot Brake System That Should Be Followed During A Lathe Oil Change?

Yes, there are tips for the foot brake system during a lathe oil change. First, make sure to clean any dust or dirt around the foot brake. Then, check the brake fluid level and add more if it looks low. You should also look for any leaks or wear on the parts. Lastly, test the brake after changing the oil to ensure it works well.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Type Of Oil Is Recommended For Changing The Lathe Oil In A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should use a light machine oil for changing the oil in a metal lathe. This type of oil helps the machine run smoothly. Look for oils that are designed for metalworking or general machine use. Always check the label to make sure it’s right for your lathe.”}},{“@type”: “Question”,”name”: “How Often Should The Lathe Oil Be Changed To Ensure Optimal Performance Of The Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should change the lathe oil every 3 to 6 months. This helps keep your metal lathe running smoothly. If you use it a lot, change it more often. Always check for dirt or dust in the oil, too!”}},{“@type”: “Question”,”name”: “What Steps Should Be Taken To Safely Change The Lathe Oil In A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To change the lathe oil safely, first, turn off the machine and unplug it. Then, let the lathe cool down if it was used recently. Next, locate the oil drain plug and place a clean container under it. Open the plug to let the old oil drain out completely. Finally, refill with fresh lathe oil, close the plug, and clean any spills.”}},{“@type”: “Question”,”name”: “How Does The Functionality Of The Foot Brake In A Metal Lathe Affect The Oil Change Process? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The foot brake on a metal lathe stops the machine quickly. When you change the oil, you want the lathe to be completely still. If the foot brake works well, it helps stop the lathe fast and safely. This makes it easier to drain old oil and add new oil. So, a good foot brake helps keep everything running smoothly during the oil change.”}},{“@type”: “Question”,”name”: “Are There Specific Maintenance Tips For The Foot Brake System That Should Be Followed During A Lathe Oil Change? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there are tips for the foot brake system during a lathe oil change. First, make sure to clean any dust or dirt around the foot brake. Then, check the brake fluid level and add more if it looks low. You should also look for any leaks or wear on the parts. Lastly, test the brake after changing the oil to ensure it works well.”}}]}