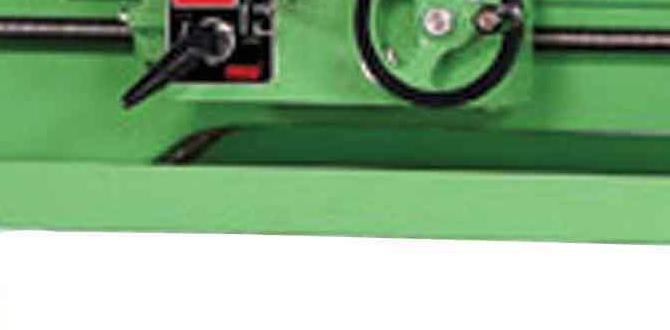

Have you ever wondered how the machines work in a metal shop? One important part of their care is the lathe oil change. Keeping your gear running smoothly needs regular attention. Neglecting this can lead to costly repairs.

Think about your bicycle chain. If it gets rusty and dry, it won’t pedal well. The same goes for the gear in a lathe. It needs oil to operate effectively. If you’re new to metalworking, this might sound tricky. But don’t worry! Learning about lathe oil is easier than it seems.

Did you know that oil helps reduce friction and wear? It keeps the gears happy and functioning. Performing a lathe oil change can boost the machine’s life. This simple task today keeps your tools in top shape for tomorrow’s projects.

Join us as we dive into how to change the oil in your metal lathe. You’ll learn tips and tricks to handle this vital task smoothly. Soon, you’ll be a pro at keeping your gear in perfect condition!

Lathe Oil Change: Essential For Metal Lathe Gear Performance

Lathe Oil Change: Boost Your Metal Lathe Gear Performance

Changing lathe oil is vital for keeping your metal lathe gear running smoothly. Regular oil changes reduce wear and tear on the machine, ensuring it stays in top shape. Did you know that dirty oil can cause unnecessary friction and damage? Keeping an eye on oil levels also helps maintain optimal performance. By choosing the right oil and following simple steps, you can extend the life of your lathe and achieve better results. Don’t let neglect slow you down!Understanding the Importance of Lathe Oil

Role of lubrication in metal lathe performance. Consequences of neglecting oil changes.Lubrication is key for your metal lathe. It keeps parts running smoothly. Without it, friction can wear down gears. Over time, this can lead to costly repairs or even complete breakdowns. It’s like oil for an engine; without it, nothing runs right. Regular oil changes are vital. Here’s why:

- Less wear and tear.

- Better performance.

- Longer machine life.

Don’t skip oil changes. It can save you time and money in the long run.

Why is lathe oil so important?

Lathe oil helps reduce friction and keeps your machine in top shape. Regular oil changes prevent damage and ensure smooth operation.

Signs That Your Lathe Needs an Oil Change

Common indicators of oil deterioration. Frequency guidelines for oil changes based on usage.Understanding when to change oil in your lathe is important. Look for these signs:

- Dark or thick oil: If the oil looks dirty or sticky, it’s time to change it.

- Unusual noises: Grinding or rattling sounds can mean low oil quality.

- Overheating: If your lathe gets too hot, the oil may be old.

For frequent use, change the oil every 40 to 50 hours. If you use it less often, aim for changes every 6 months. Regular maintenance keeps your machine running smoothly!

How often should I change the oil in my lathe?

It’s wise to change it every 40 to 50 hours of use. For light use, changing every 6 months can work well. Keep an eye on performance to know for sure!

Step-by-Step Guide to Changing Lathe Oil

Preparation: tools and materials needed. Detailed procedure for draining old oil and adding new oil.Changing lathe oil is pretty easy! First, grab the right tools: a wrench, a container for old oil, and fresh lathe oil. Don’t forget a funnel, or things might get a little slippery. Begin by draining the old oil into the container. Make sure to peek inside for any metal bits—it’s like a treasure hunt, but not the fun kind. Next, fill it up with new oil using the funnel, like filling a car with gas. Simple, right?

| Tools | Materials |

|---|---|

| Wrench | Fresh Lathe Oil |

| Oil Container | Funnel |

Best Practices for Maintaining Lathe Gears

Recommended routine maintenance schedules. Tips to enhance the longevity of lathe gear components.To keep your lathe gears happy, set up a regular maintenance routine. Check the oil at least once a month, and give those gears a good wipe down. Cleaning keeps dirt away, which is like armor for your gears. For a longer lifespan, use high-quality oil—think of it as a spa day for your lathe! Also, don’t forget to tighten loose screws; they tend to throw parties and invite rattling noises.

| Task | Frequency |

|---|---|

| Check oil level | Monthly |

| Clean gears | Monthly |

| Tighten screws | As needed |

By following these simple steps, you can keep your lathe gears running smoothly. Remember, a happy lathe makes for a productive workspace!

Common Mistakes to Avoid During Oil Change

Missteps that can lead to operational issues. How to ensure a thorough and effective oil change.Changing oil is important for keeping your metal lathe working well. However, small mistakes can cause big problems. Avoid these missteps:

- Not cleaning parts before adding new oil can trap dirt.

- Skipping the filter replacement lets old oil mix with new.

- Using the wrong type of oil can harm the gears.

To do a proper oil change, remember to:

- Always check your manual for the correct oil type.

- Clean the area and parts before starting.

- Run the lathe briefly after the change to circulate the oil.

Following these tips will keep your lathe gear running smoothly and extend its life.

Why is replacing gear oil essential?

Replacing gear oil keeps the lathe’s gears lubricated. This helps reduce wear and tear. Proper maintenance leads to better performance and fewer repairs.

FAQs About Lathe Oil Change

Answers to common queries about oil types and maintenance practices. Troubleshooting issues related to lubrication and performance.Worried about lathe oil? You’re not alone! Many people wonder about the right oil types and how often to change it. Remember to use high-quality lubricant for the best results. It’s like giving your lathe a refreshing drink on a hot day! If you notice any strange noises or reduced performance, it might be time for some troubleshooting. Check that the oil is clean and at the correct level. A good lathe feels like it could dance, so keep it happy!

| Common Issues | Solutions |

|---|---|

| Strange noises | Check oil levels and quality |

| Poor performance | Change the oil |

| Overheating | Ensure proper lubrication |

Conclusion

In summary, changing the lathe oil in your metal lathe is important for smooth operation. Regular maintenance helps to keep the gears running well. You should check the oil level often and replace it as needed. This simple step can extend your machine’s life. For more tips, explore guides on lathe care and maintenance to enhance your skills!FAQs

What Type Of Oil Is Recommended For Changing The Lathe Oil In A Metal Lathe Gear System?You should use a lightweight oil, like 10-weight or 20-weight. This oil helps the gears move smoothly. It’s important to choose oil made for machines. Always check the manual for your lathe to be sure. Regular oil changes keep your lathe working well!

How Often Should The Oil Be Changed In A Metal Lathe, And What Signs Indicate That It Needs Changing?You should change the oil in a metal lathe every 50 hours of use or once a month. Look for signs like a dirty or dark color, a smell, or strange noises from the machine. If you see any metal shavings in the oil, that’s a sign it needs changing, too. Keeping the oil fresh helps the lathe work well!

What Is The Proper Procedure For Draining And Replacing The Lathe Oil In A Gear Box?To drain and replace the lathe oil in a gear box, start by turning off the lathe. Next, find the drain plug and use a wrench to open it. Let the old oil pour out into a container. Once it’s empty, close the drain plug and fill the gear box with new oil through the fill plug. Finally, make sure everything is tight and clean up any spills!

Are There Specific Maintenance Tips For Ensuring Optimal Performance Of The Lathe Gears After An Oil Change?Yes! After changing the oil in the lathe gears, you should check for leaks. Make sure to clean the gear area to remove dirt. You can also run the lathe for a few minutes to help the new oil spread. Always listen for strange noises while it runs, as these can be signs of problems. Finally, remember to check the oil level regularly to keep everything working well.

How Do Temperature And Operating Conditions Affect The Choice And Frequency Of Lathe Oil Changes In Metal Lathes?Temperature and operating conditions can change how we use lathe oil in metal lathes. If it’s hot, oil can break down faster. This means we might need to change it more often. When the lathe works harder, like cutting tough metal, we should also change the oil more frequently. Keeping the oil clean helps the lathe run better and last longer.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Type Of Oil Is Recommended For Changing The Lathe Oil In A Metal Lathe Gear System? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should use a lightweight oil, like 10-weight or 20-weight. This oil helps the gears move smoothly. It’s important to choose oil made for machines. Always check the manual for your lathe to be sure. Regular oil changes keep your lathe working well!”}},{“@type”: “Question”,”name”: “How Often Should The Oil Be Changed In A Metal Lathe, And What Signs Indicate That It Needs Changing? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should change the oil in a metal lathe every 50 hours of use or once a month. Look for signs like a dirty or dark color, a smell, or strange noises from the machine. If you see any metal shavings in the oil, that’s a sign it needs changing, too. Keeping the oil fresh helps the lathe work well!”}},{“@type”: “Question”,”name”: “What Is The Proper Procedure For Draining And Replacing The Lathe Oil In A Gear Box? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To drain and replace the lathe oil in a gear box, start by turning off the lathe. Next, find the drain plug and use a wrench to open it. Let the old oil pour out into a container. Once it’s empty, close the drain plug and fill the gear box with new oil through the fill plug. Finally, make sure everything is tight and clean up any spills!”}},{“@type”: “Question”,”name”: “Are There Specific Maintenance Tips For Ensuring Optimal Performance Of The Lathe Gears After An Oil Change? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes! After changing the oil in the lathe gears, you should check for leaks. Make sure to clean the gear area to remove dirt. You can also run the lathe for a few minutes to help the new oil spread. Always listen for strange noises while it runs, as these can be signs of problems. Finally, remember to check the oil level regularly to keep everything working well.”}},{“@type”: “Question”,”name”: “How Do Temperature And Operating Conditions Affect The Choice And Frequency Of Lathe Oil Changes In Metal Lathes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Temperature and operating conditions can change how we use lathe oil in metal lathes. If it’s hot, oil can break down faster. This means we might need to change it more often. When the lathe works harder, like cutting tough metal, we should also change the oil more frequently. Keeping the oil clean helps the lathe run better and last longer.”}}]}