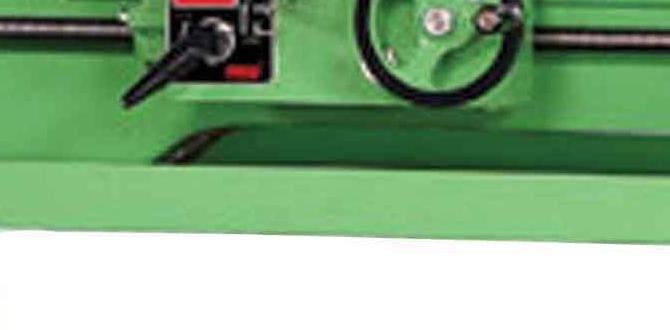

Have you ever wondered what keeps a metal lathe running smoothly? You might be surprised to learn that lathe oil plays a crucial role in its performance. Just like a car needs oil, a metal lathe needs regular oil changes to function well.

Imagine working on a project, honing the perfect piece of metal, when suddenly the handwheel becomes hard to turn. Frustrating, right? This often happens when the machine lacks proper lubrication. Regular lathe oil changes help avoid these problems and keep your lathe in top shape.

Did you know that machines can wear out faster without the right care? Just as we maintain our bikes or cars, we should care for our tools too. In this article, we will explore why lathe oil changes are important and how to do it effectively. So, let’s dive in and learn how to keep that lathe moving smoothly!

Lathe Oil Change: Essential Tips For Metal Lathe Handwheel Maintenance

Lathe Oil Change for Metal Lathe Handwheel

Changing the lathe oil is crucial for keeping your metal lathe running smoothly. Did you know that regular oil changes can extend the life of your machine? It’s not just about performance; it’s also about safety. By maintaining the handwheel’s lubrication, you prevent wear and tear. Imagine the hassle of a breakdown! A quick oil change can save you time and money. Discover tips for performing an effective oil change to ensure your lathe stays in top shape.Understanding Lathe Oil and Its Importance

Definition of lathe oil and its role in metal lathes. Benefits of regular oil changes for machine longevity and performance.Lathe oil is a special lubricant used in metal lathes. It keeps the machine parts moving smoothly. Regular oil changes help machines last longer and work better. Without enough oil, parts can wear out or get stuck. This can cause more repairs and costs.

- Prevents rust and corrosion.

- Ensures smooth operation.

- Improves overall performance.

What are the benefits of lathe oil changes?

Regular lathe oil changes help keep lathes in great shape. This leads to fewer breakdowns and better output. Over oiling can lead to a buildup of dirt, so the right amount is key.

Preparing for an Oil Change

Essential tools and materials needed for the oil change process. Safety precautions to take before starting the oil change.Getting ready for an oil change is like preparing for a fun game. First, gather your tools: a wrench, a container for old oil, and fresh lathe oil. Don’t forget a clean rag! Safety is key here; wear gloves and goggles to keep your hands clean and your eyes safe. No one wants oily fingers or surprise eye showers! And remember, don’t forget to turn off the machine and unplug it first. Safety first, oil later!

| Essential Tools | Safety Precautions |

|---|---|

| Wrench | Wear gloves |

| Old oil container | Use goggles |

| Fresh lathe oil | Unplug the machine |

Step-by-Step Process for Changing Lathe Oil

Detailed instructions on draining old oil effectively. How to clean the oil reservoir and components before refilling.To change lathe oil effectively, first drain the old oil. Locate the drain plug and remove it. Allow the oil to flow out completely. Next, clean the oil reservoir. You can use a soft cloth and a gentle cleaner. Wipe all parts inside the reservoir, removing any dirt or old oil residue. This ensures fresh oil works better. Once everything is clean, replace the drain plug securely before refilling.

How do you drain lathe oil?

Begin by finding the drain valve and letting the oil flow out completely. This keeps your lathe running smoothly.

Steps to Clean the Reservoir:

- Use a soft cloth.

- Apply a gentle cleaner.

- Wipe away dirt and residue.

- Ensure no old oil remains.

How to Refill Your Metal Lathe with Fresh Oil

Proper techniques for refilling the lathe without overfilling. Tips on checking oil levels postrefill for optimal performance.Refilling your metal lathe with oil is as easy as pie—well, almost! First, make sure to stop the lathe and let it cool down. Use a clean funnel to add fresh oil slowly; this keeps you from overfilling and causing a mess. Keep an eye on the oil window as you pour. Once you’re done, check the oil level again. Remember, a happy lathe means a happy you. If the oil has a funny face in the window, it’s time for a change!

| Steps | Tips |

|---|---|

| 1. Stop the lathe | Don’t burn your fingers! |

| 2. Use a funnel | No spills, no thrills! |

| 3. Check the level | Too high? You might have a fountain! |

Maintaining Your Lathe After Oil Change

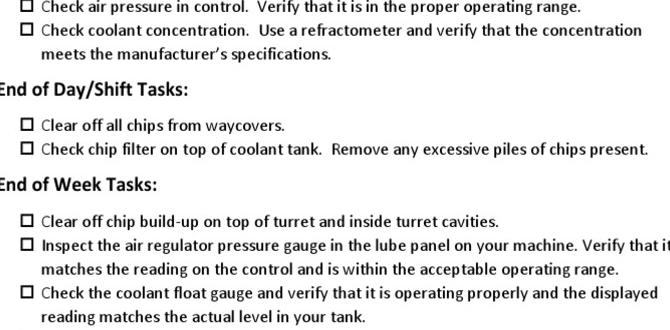

Best practices for ongoing lathe care following an oil change. Signs that indicate a need for future oil changes and maintenance.After changing the oil in your lathe, proper care is crucial. Regular maintenance helps your lathe work better and last longer. Always check for smooth movement of the handwheel. Listen for strange noises while it runs. Keep an eye on the oil level. Proper oil helps to prevent problems. Here are some tips:

- Check oil level monthly.

- Cleans parts to prevent dirt buildup.

- Look for leaks around the oil seal.

If you notice the lathe getting hotter than usual or squeaking, it’s time for another oil change. Proper maintenance keeps your lathe running smoothly!

How often should I change lathe oil?

Change lathe oil every 3 to 6 months, depending on usage. More use means more frequent changes!

Addressing Common Issues Related to Lathe Oil Usage

Troubleshooting oil leakage and contamination problems. Understanding how improper oil maintenance can affect operations.Oil issues on a lathe can be a real pain! Leaks can make your workshop look like a slip ‘n slide for bears. To fight this, check seals and hoses regularly. Contamination can sneak in too, like a ninja. Dust or dirty tools can mix with your oil, causing problems. Remember, bad oil can lead to a bad day! Proper oil care keeps things running smoothly and saves you from unexpected surprises.

| Common Issues | Solutions |

|---|---|

| Oil Leakage | Check seals and hoses. |

| Oil Contamination | Use clean tools and stay dust-free. |

When to Seek Professional Help

Indicators that your lathe may require expert servicing. Benefits of professional maintenance and inspection services.Sometimes a lathe needs a check-up. Look for these signs: strange noises, uneven cuts, or if the handwheel feels stiff. Regular checks help catch issues early. Professional help can keep your lathe running smoothly. Experts know how to spot problems that you might miss. They can extend the life of your machine and improve accuracy. It’s smart to get help when unsure.

How can professional maintenance help?

Professional maintenance ensures your lathe stays in top shape. It reduces downtime and can save money in the long run. Regular inspections lead to better quality work.

- Improved machine lifespan

- Enhanced safety

- Higher precision in work

Conclusion

In conclusion, changing lathe oil is crucial for keeping your metal lathe running smoothly. Always check the handwheel for easy adjustments. A clean lathe performs better and lasts longer. Now that you know the basics, take a moment to inspect your lathe and change its oil if needed. Happy machining, and don’t hesitate to learn more about lathe maintenance!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Oil Change For A Metal Lathe Handwheel:To change the oil in a lathe handwheel, you first need to turn off the machine and unplug it for safety. Next, find the oil reservoir, which is where the oil is stored. You can then remove any old oil by using a cloth or a pump. After that, refill the reservoir with new oil until it’s full. Finally, wipe any spills and plug the machine back in.

Sure! I can help you with that. Just let me know what question you need answered.

How Often Should I Change The Oil In My Metal Lathe Handwheel?You should change the oil in your metal lathe handwheel every six months. This keeps it working smoothly. If you use it more, change the oil more often. Always check the oil level too. A little care goes a long way!

What Type Of Oil Is Recommended For Lubrication Of The Handwheel In A Metal Lathe?You should use light machine oil to lubricate the handwheel on a metal lathe. This oil is smooth and helps the machine work better. You can find it in hardware stores. Make sure to apply just a little bit so it doesn’t make a mess.

What Are The Signs That Indicate It’S Time To Change The Oil In My Lathe?Look for a few signs to know when to change the oil in your lathe. First, check if the oil looks dirty or cloudy. If it smells bad or feels gritty, it’s time for new oil. Also, if your lathe makes strange noises when running, that could mean the oil needs changing. Regularly checking helps keep your lathe working well!

Can I Use Motor Oil For Lubricating The Handwheel Of A Metal Lathe, Or Should I Stick To Specialized Lathe Oil?You should use specialized lathe oil for your metal lathe. Motor oil is too thick and can cause problems. Lathe oil is made just for machines like yours. It helps keep everything running smoothly. Stick to the right oil for the best care!

What Steps Should I Follow To Properly Change The Oil In My Metal Lathe Handwheel?To change the oil in your metal lathe handwheel, first, make sure the lathe is off and cool. Then, find the oil fill hole on the handwheel. Use a clean cloth to wipe around the hole. Next, pour new oil into the hole until it’s full. Finally, clean up any spills and test the handwheel to see if it moves smoothly.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Oil Change For A Metal Lathe Handwheel:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To change the oil in a lathe handwheel, you first need to turn off the machine and unplug it for safety. Next, find the oil reservoir, which is where the oil is stored. You can then remove any old oil by using a cloth or a pump. After that, refill the reservoir with new oil until it’s full. Finally, wipe any spills and plug the machine back in.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! I can help you with that. Just let me know what question you need answered.”}},{“@type”: “Question”,”name”: “How Often Should I Change The Oil In My Metal Lathe Handwheel?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should change the oil in your metal lathe handwheel every six months. This keeps it working smoothly. If you use it more, change the oil more often. Always check the oil level too. A little care goes a long way!”}},{“@type”: “Question”,”name”: “What Type Of Oil Is Recommended For Lubrication Of The Handwheel In A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should use light machine oil to lubricate the handwheel on a metal lathe. This oil is smooth and helps the machine work better. You can find it in hardware stores. Make sure to apply just a little bit so it doesn’t make a mess.”}},{“@type”: “Question”,”name”: “What Are The Signs That Indicate It’S Time To Change The Oil In My Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Look for a few signs to know when to change the oil in your lathe. First, check if the oil looks dirty or cloudy. If it smells bad or feels gritty, it’s time for new oil. Also, if your lathe makes strange noises when running, that could mean the oil needs changing. Regularly checking helps keep your lathe working well!”}},{“@type”: “Question”,”name”: “Can I Use Motor Oil For Lubricating The Handwheel Of A Metal Lathe, Or Should I Stick To Specialized Lathe Oil?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should use specialized lathe oil for your metal lathe. Motor oil is too thick and can cause problems. Lathe oil is made just for machines like yours. It helps keep everything running smoothly. Stick to the right oil for the best care!”}},{“@type”: “Question”,”name”: “What Steps Should I Follow To Properly Change The Oil In My Metal Lathe Handwheel?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To change the oil in your metal lathe handwheel, first, make sure the lathe is off and cool. Then, find the oil fill hole on the handwheel. Use a clean cloth to wipe around the hole. Next, pour new oil into the hole until it’s full. Finally, clean up any spills and test the handwheel to see if it moves smoothly.”}}]}