Have you ever wondered how a small amount of oil can keep big machines running smoothly? In the world of metal lathes, lathe oil is crucial. It doesn’t just help the lead screw glide; it keeps everything in perfect shape.

Changing lathe oil might sound boring, but it is exciting! Imagine being the person who ensures your machine works flawlessly. Not many know that a simple oil change can make a big difference in tool performance.

When the lead screw gets dirty, it can slow down the machine. Think of it like your bike chain needing oil. Without it, pedaling becomes tough! That’s why knowing when and how to change lathe oil is important.

In this article, you’ll discover tips and tricks for a smooth lathe oil change. Let’s dive into the world of lathes and explore how a little oil can go a long way!

Lathe Oil Change: Essential For Metal Lathe Lead Screw Maintenance

Lathe Oil Change for Metal Lathe Lead Screw

Changing lathe oil is crucial for keeping a metal lathe running smoothly. Over time, oil gets dirty and can cause wear and tear. Regular oil changes can extend the life of your lead screw and improve performance. Did you know that poor lubrication can lead to costly repairs? Checking oil levels is an easy task that can save you headaches later. Remember, fresh lathe oil helps your machine work better and last longer!Understanding the Importance of Lathe Oil

Role of lubrication in metal lathes. Consequences of neglecting oil changes.Lubrication is like the magic potion for metal lathes! It helps the machine run smoothly and protects it from wear and tear. Without enough oil, parts can grind against each other, leading to damage. Imagine your favorite toy getting stuck—nobody wants that! Neglecting regular oil changes can mean big problems, like uneven cuts and breakdowns. Keep your lathe happy with fresh oil, and it will love you back!

| Consequence of Neglecting Oil Changes | What Happens? |

|---|---|

| Increased wear | Parts wear out faster, leading to costly repairs. |

| Overheating | Machines can get too hot and stop working! |

Signs that It’s Time for an Oil Change

Indicators of degraded oil quality. Performance issues related to oil condition.It’s crucial to notice when your oil is losing its quality. Look for signs like dark, thick, or gritty oil. Performances may drop if the oil is worn out. You could feel lag during operations or hear strange noises. Be alert to any unusual vibrations, too. Here are some signs to check:

- Oil appears dark or smells burnt.

- Machine runs unevenly or makes odd sounds.

- Motions feel sluggish or have delays.

What are common signs of degraded oil?

Common signs include dark color, strange noises, and slow movements. Keep a close watch on your metal lathe. Regular checks can save you time and money later.

Tools and Materials Needed for Oil Change

Essential tools for the oil change process. Recommended oil types for different lathe models.Changing oil in your lathe is important. You need the right tools and materials to do it well. Here are the essential items for the job:

- Wrenches: To loosen and tighten bolts.

- Screwdrivers: For any screws that need to be removed.

- Oil Catch Pan: To collect old oil safely.

- New Oil: Always use recommended oil types based on your lathe model.

Different lathe models may need specific oils. Using the correct oil ensures smooth operation and longer tool life. Check your manual for the best choices.

What oil should you use for my lathe?

It depends on your lathe model. Each model has its recommendations. Always refer to the manual for the best oil type. This helps keep your lathe running smoothly and efficiently.

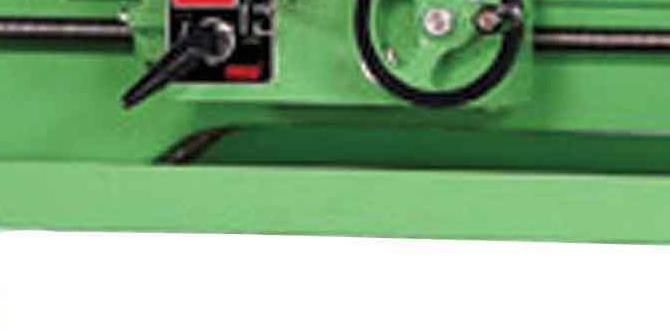

Step-by-Step Process for Changing Lathe Oil

Preparing the lathe for oil change. Detailed steps to drain old oil and refill.Before you change the lathe oil, make sure your workspace is clean and your lathe is off. Safety first! Next, gather your tools: a container for old oil, a wrench, and fresh lathe oil. Now, let’s get to the fun part. To drain the old oil, take off the plug and let it flow into your container. It’s like a mini waterfall! Once it’s empty, don’t forget to put the plug back. Then, refill with the new oil until it’s just right. Not too full, or it will spill like your coffee on a Monday morning!

| Step | Action |

|---|---|

| 1 | Turn off the lathe and clean the area. |

| 2 | Gather tools: container, wrench, and oil. |

| 3 | Drain the old oil into a container. |

| 4 | Replace the plug. |

| 5 | Fill with new lathe oil. |

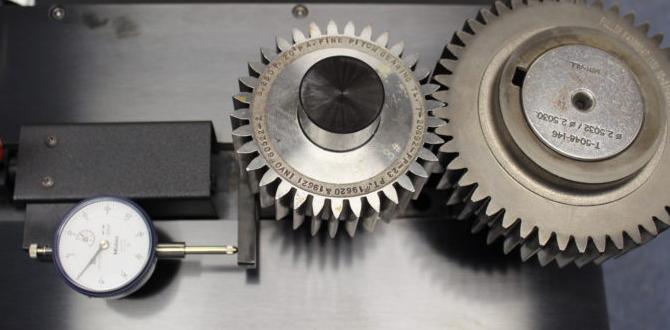

Maintaining Your Lead Screw: Best Practices

Cleaning and inspecting the lead screw. Tips for ensuring a long lifespan for lead screws.Keeping your lead screw clean is key to its health. Dust and gunk can sneak in and ruin everything. Grab a soft cloth and give it a good wipe down. Inspect for any wear and tear, like a detective on a mission! For a long lifespan, remember to lubricate often. Think of it as giving your lead screw a spa day—it deserves a little pampering!

| Best Practices | Description |

|---|---|

| Clean Regularly | Wipe down the lead screw to remove dust and debris. |

| Inspect Often | Look for wear and damage; catch problems early! |

| Lubricate | Use quality lathe oil for smooth operation. |

Stay on top of these tips, and your lead screw will be happy. A happy lead screw makes for a happy metal lathe! And remember, “An ounce of prevention is worth a pound of cure,” or in lathe terms, one clean screw is worth its weight in shiny metal parts!

Common Mistakes to Avoid During Oil Change

Frequent errors made by beginners. How to prevent oil change pitfalls.Many beginners make mistakes during oil changes. Skipping steps can lead to problems. Here are some common errors to avoid:

- Not cleaning the parts before adding new oil.

- Using the wrong type of oil.

- Failing to check oil levels after the change.

- Rushing the process instead of taking time.

To prevent these pitfalls, always follow the instructions carefully. Make sure to have the right tools and supplies ready. Taking your time will help ensure a smooth oil change.

What should I check during an oil change?

Check oil levels, the cleanliness of parts, and confirm you’re using the correct oil type.

Frequency of Oil Changes: How Often Should You Change Lathe Oil?

Factors influencing oil change frequency. General guidelines for different usage scenarios.Changing lathe oil can feel like a mystery, but fear not! The frequency of oil changes depends on how much you use your lathe and the materials you work with. For light usage, changing the oil every few months is usually enough. However, if you’re a hobbyist who loves to tinker, consider changing it every month. Fun fact: Too old oil is like stale bread – it just doesn’t work well! Always check for noise or roughness; these are signs your lathe needs some TLC. Here’s a simple guide:

| Usage | Recommended Oil Change Frequency |

|---|---|

| Light usage | Every 3-6 months |

| Moderate usage | Every 1-3 months |

| Heavy usage | Every month |

Understanding Oil Specifications and Ratings

Explanation of oil ratings. How to choose the right oil for specific lathe models.Oil specifications matter for your lathe’s health. Ratings tell you how thick or thin the oil is. Thicker oil can protect better, while thinner oil works well in colder temps. Make sure to check the manufacturer’s guide for your specific lathe model. This way, your lathe stays smooth and happy.

How do I choose the right oil for my lathe?

Choosing the right oil is easy. Look for these points:

- Check the machine’s manual.

- Use oil with the right viscosity.

- Consider the climate. Cold oil works best in cold weather.

FAQs About Lathe Oil Change and Maintenance

Common questions from lathe users. Expert answers to enhance user knowledge.Many users wonder about the best ways to maintain their lathe machines. It’s important to keep your tools running smoothly. Here are some common questions and expert answers that can help you:

What is the right oil for my lathe?

Use specially made lathe oil. This oil helps to protect and lubricate the machine parts.

How often should I change the lathe oil?

Change the oil every 50 hours of use. This keeps your lathe in top shape.

Can I clean the lead screw?

Yes, clean it carefully with a soft cloth. Remove dirt and old oil to keep it moving well.

- Regular maintenance prolongs the lathe’s life.

- Always follow the manual for specific care tips.

- Ask experts if you’re unsure about any step.

Conclusion

In summary, changing lathe oil is crucial for keeping your metal lathe running smoothly. Regular oil changes protect your lead screw from wear and tear. It’s simple to do and improves your machine’s lifespan. Remember to check your oil often. You can find more tips online to help you maintain your lathe. Let’s keep your projects running perfectly!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Oil Change For A Metal Lathe Lead Screw:To change the oil on a metal lathe’s lead screw, first, you need to turn off the machine. Then, find the oil pan and drain out the old oil. Be careful to not spill it! Next, fill the pan with fresh lathe oil until it reaches the right level. Finally, run the lathe for a few minutes to make sure the oil spreads everywhere. That’s it!

Sure! I can help with that. Please type your question, and I will answer it in a simple way.

What Type Of Oil Is Recommended For Lubricating The Lead Screw Of A Metal Lathe?To lubricate the lead screw of a metal lathe, you should use machine oil or ways oil. These oils are good because they help the parts move smoothly. You can find them at hardware stores. Remember to check your lathe’s manual for specific recommendations. Keeping the lead screw oiled will help your lathe work better!

How Often Should The Oil Be Changed For The Lead Screw Of A Metal Lathe To Ensure Optimal Performance?You should change the oil for the lead screw of a metal lathe every three to six months. This helps keep the lathe running smoothly. It’s also good to check the oil regularly. If it looks dirty or thick, change it sooner. Keeping it clean helps your lathe work better and last longer!

What Are The Steps Involved In Performing An Oil Change For The Lead Screw On A Metal Lathe?To change the oil in the lead screw of a metal lathe, you start by turning off the lathe and unplugging it. Next, find the oil fill hole. Use a clean cloth to wipe around it. Then, remove the old oil by draining it into a container. Finally, fill the lead screw with fresh oil, making sure not to overfill. Remember to clean up any spills!

What Signs Indicate That The Lead Screw Of A Metal Lathe Needs Lubrication Or An Oil Change?You can tell the lead screw needs oil when it starts to feel sticky or hard to move. If you hear squeaking or grinding noises, that’s another sign. You might also see dust or dirt around it. If the oil looks dirty or brown, it’s time for a change. Keeping it well-lubricated helps it run smoothly!

Are There Specific Safety Precautions To Take When Changing The Oil On A Metal Lathe’S Lead Screw?Yes, there are safety precautions when changing oil on a metal lathe’s lead screw. First, turn off the machine and unplug it. Always wear safety glasses to protect your eyes. Make sure your hands are clean and dry to avoid slipping. Finally, check that you have the right tools and oil before you start.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Oil Change For A Metal Lathe Lead Screw:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To change the oil on a metal lathe’s lead screw, first, you need to turn off the machine. Then, find the oil pan and drain out the old oil. Be careful to not spill it! Next, fill the pan with fresh lathe oil until it reaches the right level. Finally, run the lathe for a few minutes to make sure the oil spreads everywhere. That’s it!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! I can help with that. Please type your question, and I will answer it in a simple way.”}},{“@type”: “Question”,”name”: “What Type Of Oil Is Recommended For Lubricating The Lead Screw Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To lubricate the lead screw of a metal lathe, you should use machine oil or ways oil. These oils are good because they help the parts move smoothly. You can find them at hardware stores. Remember to check your lathe’s manual for specific recommendations. Keeping the lead screw oiled will help your lathe work better!”}},{“@type”: “Question”,”name”: “How Often Should The Oil Be Changed For The Lead Screw Of A Metal Lathe To Ensure Optimal Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should change the oil for the lead screw of a metal lathe every three to six months. This helps keep the lathe running smoothly. It’s also good to check the oil regularly. If it looks dirty or thick, change it sooner. Keeping it clean helps your lathe work better and last longer!”}},{“@type”: “Question”,”name”: “What Are The Steps Involved In Performing An Oil Change For The Lead Screw On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To change the oil in the lead screw of a metal lathe, you start by turning off the lathe and unplugging it. Next, find the oil fill hole. Use a clean cloth to wipe around it. Then, remove the old oil by draining it into a container. Finally, fill the lead screw with fresh oil, making sure not to overfill. Remember to clean up any spills!”}},{“@type”: “Question”,”name”: “What Signs Indicate That The Lead Screw Of A Metal Lathe Needs Lubrication Or An Oil Change?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can tell the lead screw needs oil when it starts to feel sticky or hard to move. If you hear squeaking or grinding noises, that’s another sign. You might also see dust or dirt around it. If the oil looks dirty or brown, it’s time for a change. Keeping it well-lubricated helps it run smoothly!”}},{“@type”: “Question”,”name”: “Are There Specific Safety Precautions To Take When Changing The Oil On A Metal Lathe’S Lead Screw?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there are safety precautions when changing oil on a metal lathe’s lead screw. First, turn off the machine and unplug it. Always wear safety glasses to protect your eyes. Make sure your hands are clean and dry to avoid slipping. Finally, check that you have the right tools and oil before you start.”}}]}