Have you ever wondered how metal lathe machines stay in top shape? One key part of that is the lathe oil change. Just like your bike needs oil for smooth rides, these machines need it too. When you keep the oil fresh, your lathe runs better and lasts longer.

Imagine working on an exciting project. Suddenly, your lathe starts to make strange noises. This could mean it needs a good oil change! Taking care of your machine can save you time and money in the long run. Did you know that regular maintenance can keep it running for years? It’s true!

In this article, we’ll explore the importance of lathe oil changes. We will break down the process, share tips, and answer any questions you may have. Ready to learn how to take care of your metal lathe machine? Let’s get started!

Lathe Oil Change: Essential Maintenance For Metal Lathe Machine

Lathe Oil Change in Metal Lathe Machines

Regularly changing the lathe oil keeps your metal lathe machine running smoothly. Clean oil can reduce friction and wear on parts, ensuring your machine lasts longer. Did you know that dirty oil can cause overheating? To avoid breakdowns, check the oil level and quality often. When you notice dark or gritty oil, it’s time for a change. Taking care of your lathe is like caring for a pet; it requires attention and maintenance to work its best.

Understanding the Importance of Lathe Oil

Role of lathe oil in machine performance. Consequences of neglecting regular oil changes.

Lathe oil plays a crucial role in keeping machines happy and running smoothly. It helps reduce friction, which is like giving your metal lathe a warm hug! Regular oil changes are essential, though. Skip them, and you risk wear and tear on your machine. Think of it this way: neglecting oil changes is like asking a car to run without gas! Make sure to keep that oil fresh for great performance.

| Consequence of Neglect | Result |

|---|---|

| Overheating | Machine Breakdowns |

| Increased Wear | Shortened Lifespan |

| Poor Performance | Inaccurate Cuts |

Signs It’s Time to Change Your Lathe Oil

Indicators of old or contaminated oil. Recommended oil change intervals based on usage.

Old or contaminated lathe oil can cause problems for your metal lathe machine. Here are signs you need to watch for:

- Oil looks dirty or dark.

- There are strange smells coming from the oil.

- Strange noises from the machine.

As for changing the oil, if you use your lathe often, aim for an oil change every 30-60 days. If it’s less frequent, check it every few months. Regular checks keep your machine running smoothly.

How often should I change lathe oil?

Change lathe oil every 30-60 days for heavy use. For light users, check every few months.

Step-by-Step Guide to Changing Lathe Oil

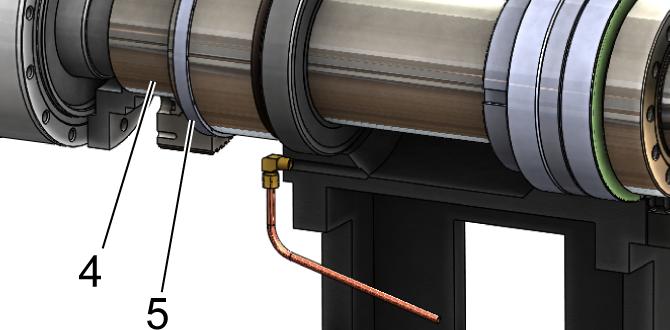

Tools and materials needed for the oil change. Detailed procedure for draining old oil and applying new oil.

To change lathe oil, gather a few tools and materials. You’ll need:

- New lathe oil

- Oil drain pan

- Wrenches

- Cloth or rag

First, turn off the machine. Place the oil drain pan under the drain plug. Unscrew the drain plug and let the old oil flow out. Clean the plug before closing it again. Finally, pour in the new oil. Make sure it reaches the right level.

What are the steps to change lathe oil?

The steps include gathering tools, draining old oil, cleaning parts, and adding new oil. Always remember to check the oil level after adding new oil.

Maintenance Tips for Longevity of Lathe Machines

Additional maintenance practices alongside oil changes. Importance of regular inspection and cleaning.

To keep your lathe machine happy and running smoothly, it needs more than just an oil change. Regular inspections are your best friend! Check for loose parts or weird noises—think of it as a wellness check-up for your machine. Don’t forget to clean it regularly; a clean lathe is a happy lathe! Dirt can cause big problems, like a bad hair day but for machines. Here’s a quick table for your maintenance checklist:

| Maintenance Task | Frequency |

|---|---|

| Oil Change | Every 50 hours |

| Inspection | Weekly |

| Cleaning | After Each Use |

Remember, a little effort goes a long way. Keep it clean, keep it checked, and your lathe will thank you with smooth operations—no one likes a cranky lathe!

Common Mistakes to Avoid During Oil Change

Pitfalls in the oil changing process. How to mitigate risks of damage to the lathe machine.

Changing oil in a lathe machine can be tricky. Many mistakes can lead to problems. One common pitfall is using the wrong oil type. Always check the manufacturer’s guidelines. Also, not cleaning the area properly can cause dirt and debris to enter the machine.

- Check oil color and viscosity.

- Replace oil filters regularly.

- Prevent spills by using a funnel.

To protect your lathe, always follow these steps. Take your time and double-check everything. It can save you from costly repairs.

What is the importance of regular oil changes?

Regular oil changes keep your lathe machine running smoothly. They prevent wear and tear, extending the machine’s life. It’s crucial for maintaining performance and efficiency.

FAQs about Lathe Oil Changes

Addressing common queries and misconceptions. Expert advice and best practices for users.

People often wonder about changing oil in their metal lathe machines. It’s important to understand the basics and avoid confusion. Here are some common questions answered:

How often should I change lathe oil?

Change lathe oil every 50 hours of use to keep your machine running smoothly.

What type of oil should I use?

Use high-quality machine oil designed for metal lathes.

Can I mix different oils?

Avoid mixing oils. Stick to one type for best results.

Expert Tips:

- Check oil levels regularly.

- Look for signs of contamination.

- Follow your machine’s manual for specific needs.

By following these tips, you can keep your lathe in top shape and help it last longer!

Conclusion

In summary, changing lathe oil is essential for keeping your metal lathe machine running smoothly. It helps reduce friction and prevents wear. Remember to check the oil regularly and replace it when needed. You can improve your machine’s performance with this simple task. For more tips, explore guides on maintenance or watch instructional videos to learn more about lathe care!

FAQs

What Are The Signs That Indicate It’S Time To Change The Lathe Oil In A Metal Lathe Machine?

You should change the lathe oil when it looks dirty or dark. If you hear strange noises while the machine runs, that’s another sign. Also, if the oil smells bad or is thick, it’s time for a change. Keeping the oil fresh helps the machine work better. Always check the oil regularly to keep everything running smoothly!

What Type Of Oil Is Recommended For Lubrication In A Metal Lathe Machine?

For a metal lathe machine, we recommend using machine oil. This oil helps keep the moving parts running smoothly. You can also use cutting oil for specific jobs when cutting metal. Always check your machine’s manual to see what oil it needs!

How Frequently Should Lathe Oil Be Changed To Ensure Optimal Performance Of A Metal Lathe?

You should change lathe oil every few months. If you use the lathe a lot, you might need to change it more often. Check the oil regularly. If it looks dirty, it’s time for a change. Keeping the oil fresh helps your lathe work better.

What Is The Proper Procedure For Draining And Replacing The Lathe Oil In A Metal Lathe Machine?

To drain and replace the lathe oil, first, turn off the machine and let it cool down. Next, find the oil drain plug, usually at the bottom of the machine. Open the plug and let the old oil flow into a container. Once it’s empty, close the plug and pour in new oil through the fill hole. Make sure to check the oil level and enjoy your working lathe!

Are There Any Specific Maintenance Tips To Follow When Changing Lathe Oil To Avoid Damage To The Machine?

When changing lathe oil, make sure to turn off the machine first. Always clean the area before you start. Use the right type of oil that your lathe needs. Don’t mix old oil with new oil. Finally, check for any leaks after you change the oil. This way, your lathe will stay in good shape!