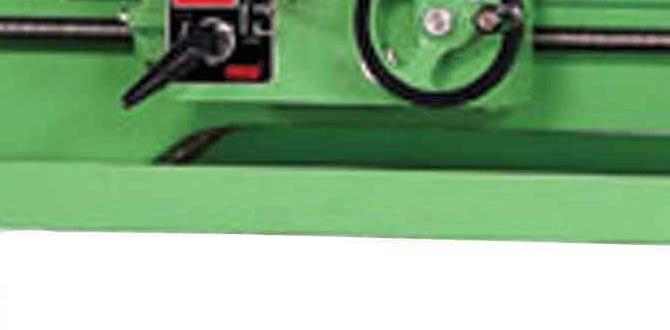

Have you ever watched a metal lathe spin and wondered how it runs so smoothly? The secret often lies in something simple: lathe oil. Just like a car needs regular oil changes, a metal lathe motor also needs care to keep it running well. But when should you change the oil? It can be hard to tell.

Imagine working on a project, feeling proud of your skills. Suddenly, your lathe starts to make strange noises. That’s no fun! Regular lathe oil changes can help prevent issues like this.

Did you know that using fresh oil can improve precision in your work? It helps reduce friction and enhances performance. It’s like giving your lathe a new pair of shoes!

In this article, we’ll explore everything you need to know about changing your lathe oil. You’ll learn step-by-step how to do it and why it matters. So, let’s dive in and keep that metal lathe motor humming smoothly!

Essential Lathe Oil Change For Metal Lathe Motor Efficiency

Key Points About Lathe Oil Change for Metal Lathe Motors

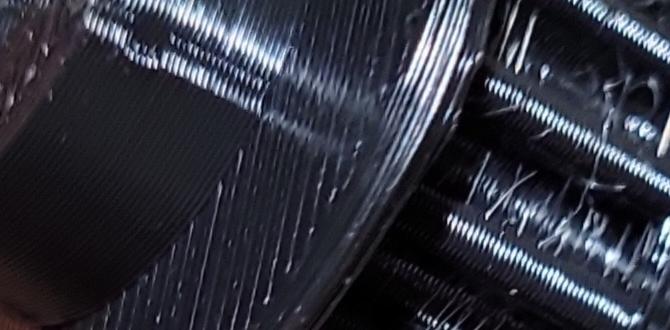

Changing lathe oil is essential for keeping your metal lathe motor running smoothly. Fresh oil helps reduce friction and extends the life of the machine. Did you know that using the right oil can prevent overheating? Regular maintenance not only improves performance but also ensures safety during operation. Keep an eye on oil levels and change it as needed to keep your lathe in top shape. It’s a small task that makes a big difference!Signs Your Metal Lathe Motor Needs an Oil Change

Common indicators of low or dirty oil. Consequences of neglecting oil changes.Every metal lathe motor whispers secrets about its health. Is it making strange noises? That’s a sign of low or dirty oil. You might also notice overheating. Don’t let that be you! Regularly check your oil levels. If you ignore this job, your motor might break down. That could cost time and money. Remember, happy lathe means happy you! Here’s a quick table of signs and what to watch for:

| Signs | Consequences |

|---|---|

| Strange noises | Motor wear-out |

| Overheating | Malfunction |

| Oil leaks | Loss of lubrication |

| Dark and dirty oil | Reduced efficiency |

Tools and Supplies Needed for an Oil Change

Essential tools for performing an oil change. Recommended types and brands of lathe oil.Changing oil is easy when you have the right tools. Here’s what you need:

- Wrench set

- Oil pan

- Funnel

- Clean rags

- Safety gloves

Choose good lathe oil for the best results. Popular brands include Mobil 1, Shell Tellus, and Pennzoil. Each one keeps your motor running smoothly. Make sure to always check your lathe’s manual for recommendations.

What is the best oil for a metal lathe?

The best oil for a metal lathe is a high-quality, non-detergent oil that lubricates well and prevents rust.Step-by-Step Guide to Changing Oil in Metal Lathe Motors

Detailed instructions for draining old oil. Procedures for adding new oil to the motor.Draining the old oil from your metal lathe motor is like getting rid of yesterday’s lunch—it’s necessary! First, turn off the motor and let it cool. Next, locate the oil drain plug and dump out the soggy oil into a container. Remember, oil can take a little splash! Then, it’s time to fill up that motor with shiny new oil. Use a fun funnel to aim perfectly and pour in the fresh oil. Don’t overflow it, or you’ll be doing the slip-and-slide dance!

| Step | Action |

|---|---|

| 1 | Turn off and cool the motor. |

| 2 | Find and drain the old oil. |

| 3 | Use a funnel to add new oil. |

It’s important to choose the right oil too! The smoothness of the motor matters. Always check your manual for the best type. Now you’re ready to spin and shine, just like a happy lathe motor!

Best Practices for Maintaining Lathe Oil Levels

Tips for regularly checking oil levels. Recommended oil change schedules for optimal performance.Keeping your lathe oil levels in check is crucial for smooth operation. First, always inspect the oil level before starting your work. Use a dipstick if available. Top it off if it’s low. Set a regular oil change schedule—every 50 hours of use is a good rule. This keeps everything running well.

- Check oil levels weekly.

- Change oil every 50 hours.

- Use the right type of oil recommended by the manufacturer.

Following these simple steps will help extend the life of your lathe. Remember, a well-maintained machine is a happy machine!

How often should lathe oil be changed?

Change lathe oil every 50 hours of use for the best performance.

Common Mistakes to Avoid During Oil Change

Mistakes that can lead to damage or inefficiency. How to properly dispose of used oil.Many people make mistakes during an oil change that can harm their metal lathe motor. One common blunder is rushing and forgetting to clean the oil filter. This could lead to dirty oil making its way back in. Also, pouring old oil down the drain is a crime against nature. Instead, take it to a recycling center. Remember, an oil change is like a spa day for your lathe—treat it well!

| Mistakes to Avoid | Why It Matters |

|---|---|

| Skipping Oil Filter Cleaning | Dirty oil can cause damage. |

| Poor Disposal of Used Oil | Environmental harm and legal issues. |

| Not Checking Levels | Oil levels can lead to motor failure. |

FAQs About Lathe Oil Changes

Answers to frequently asked questions. Clarifications on common misconceptions about lathe oil.Many people wonder about the right time to change lathe oil. The answer is simple: every six months, or after 100 hours of use! Some think any old oil will do, but that’s not true! Using the right oil helps your lathe run smoothly. Remember, dirty oil can lead to problems, like a grumpy machine. How often you use your lathe also matters—so keep an eye on that oil! Now, let’s dive into some fun FAQs!

| Question | Answer |

|---|---|

| Can I use regular motor oil? | No, it’s best to use oil made for lathes! |

| What happens if I forget to change the oil? | Your lathe might throw a tantrum! |

Additional Resources for Lathe Maintenance

Links to relevant guides and tutorials. Recommendations for further reading on lathe upkeep.Keeping your lathe in great shape is no small job! Thankfully, many helpful guides are just a click away. Think of them as your trusty sidekick on the journey to lathe maintenance. You can find expert tutorials that cover everything from changing lathe oil to keeping the motor purring like a kitten. Want to dive deeper? Check out these fantastic resources:

| Resource | Description |

|---|---|

| Lathe Oil Guide | Learn when and how to change lathe oil. |

| Maintenance Tutorial | Step-by-step methods for lathe upkeep. |

| Repair Tips | Quick fixes for common lathe problems. |

Reading these guides will make you a lathe maintenance expert. Remember, a happy lathe means happy projects!

Conclusion

In summary, changing lathe oil is essential for your metal lathe motor’s performance. Regular maintenance keeps your machine running smoothly and extends its life. Always check the oil level and replace it when needed. We encourage you to read your lathe’s manual for specific instructions. With good care, you’ll enjoy better results and a longer-lasting lathe!FAQs

Here Are Five Related Questions On The Topic Of Lathe Oil Change For A Metal Lathe Motor:Changing the oil in a metal lathe motor is important for keeping it running smoothly. First, you need to turn off the machine and unplug it. Then, locate the oil drain or plug and let the old oil run out. After that, pour in fresh oil, making sure to use the right type. Finally, check the oil level to be sure it’s just right.

Sure! Please provide the question you would like me to answer.

What Type Of Oil Is Recommended For Lubricating A Metal Lathe Motor, And How Often Should It Be Changed?For a metal lathe motor, you should use lightweight machine oil or a special motor oil. It helps the motor run smoothly. You should change the oil every few months or whenever it looks dirty. This keeps the lathe in good shape. Always check your machine’s guide for specific advice!

What Are The Key Signs That Indicate It’S Time To Change The Oil In A Metal Lathe Motor?You should change the oil in a metal lathe motor when you notice a few signs. If the oil looks dirty or dark, that’s a sign to replace it. Also, if the motor makes funny noises or runs hotter than usual, it might need new oil. Lastly, if the oil smells bad, it’s time for a change. Always check regularly to keep your motor happy!

How Do You Properly Drain And Refill The Oil In A Metal Lathe Motor?To drain the oil from a metal lathe motor, first, make sure the motor is off and cool. Then, find the oil drain plug and unscrew it carefully. Let the old oil flow into a container until it’s empty. Next, close the drain plug tightly. Finally, pour new oil into the fill hole until it reaches the right level.

Are There Specific Maintenance Tips For Ensuring Optimal Performance Of A Metal Lathe Motor During The Oil Change Process?Yes, there are some tips to keep your metal lathe motor running well during an oil change. First, make sure to turn off the machine and unplug it for safety. Second, use the right type of oil as told in the manual. Next, clean the area around the motor to keep dirt away. Finally, check for any loose parts or leaks before you finish.

What Are The Potential Consequences Of Neglecting To Change The Oil In A Metal Lathe Motor Regularly?If you don’t change the oil in a metal lathe motor, it can get dirty and thick. This can hurt the motor and make it overheat. Over time, the motor might break down completely. Then, you might have to spend a lot of money to fix it. Keeping the oil fresh helps the motor work well and last longer.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Oil Change For A Metal Lathe Motor:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Changing the oil in a metal lathe motor is important for keeping it running smoothly. First, you need to turn off the machine and unplug it. Then, locate the oil drain or plug and let the old oil run out. After that, pour in fresh oil, making sure to use the right type. Finally, check the oil level to be sure it’s just right.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Type Of Oil Is Recommended For Lubricating A Metal Lathe Motor, And How Often Should It Be Changed?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For a metal lathe motor, you should use lightweight machine oil or a special motor oil. It helps the motor run smoothly. You should change the oil every few months or whenever it looks dirty. This keeps the lathe in good shape. Always check your machine’s guide for specific advice!”}},{“@type”: “Question”,”name”: “What Are The Key Signs That Indicate It’S Time To Change The Oil In A Metal Lathe Motor?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should change the oil in a metal lathe motor when you notice a few signs. If the oil looks dirty or dark, that’s a sign to replace it. Also, if the motor makes funny noises or runs hotter than usual, it might need new oil. Lastly, if the oil smells bad, it’s time for a change. Always check regularly to keep your motor happy!”}},{“@type”: “Question”,”name”: “How Do You Properly Drain And Refill The Oil In A Metal Lathe Motor?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To drain the oil from a metal lathe motor, first, make sure the motor is off and cool. Then, find the oil drain plug and unscrew it carefully. Let the old oil flow into a container until it’s empty. Next, close the drain plug tightly. Finally, pour new oil into the fill hole until it reaches the right level.”}},{“@type”: “Question”,”name”: “Are There Specific Maintenance Tips For Ensuring Optimal Performance Of A Metal Lathe Motor During The Oil Change Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there are some tips to keep your metal lathe motor running well during an oil change. First, make sure to turn off the machine and unplug it for safety. Second, use the right type of oil as told in the manual. Next, clean the area around the motor to keep dirt away. Finally, check for any loose parts or leaks before you finish.”}},{“@type”: “Question”,”name”: “What Are The Potential Consequences Of Neglecting To Change The Oil In A Metal Lathe Motor Regularly?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If you don’t change the oil in a metal lathe motor, it can get dirty and thick. This can hurt the motor and make it overheat. Over time, the motor might break down completely. Then, you might have to spend a lot of money to fix it. Keeping the oil fresh helps the motor work well and last longer.”}}]}