If you own a metal lathe, you know it needs care. One crucial task is changing the lathe oil. But why is this important? Keeping the lathe oil fresh ensures that your machine runs smoothly and lasts longer.

Have you ever watched a lathe in action? The way it spins and shapes metal is fascinating! Yet, without proper lubrication, it can struggle and wear out quickly. Imagine trying to ride a bike with flat tires; it just doesn’t work well!

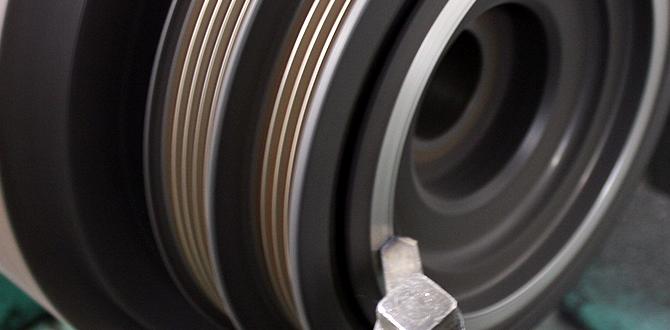

Changing the oil isn’t just about keeping things tidy; it’s about protecting your investment. A #lathe oil change can help maintain the pulley’s efficiency too. Did you know that regular oil changes can prevent costly repairs later? It’s true!

In this article, we will explore how to change your lathe oil. We’ll cover important tips and tricks to make the process easy. Let’s jump in and learn how to keep that metal lathe in top shape!

Essential Guide To Lathe Oil Change For Metal Lathe Pulley

Lathe Oil Change for Metal Lathe Pulley

Changing oil in a metal lathe pulley keeps your machine running smoothly. Regular oil changes minimize wear and tear, helping you avoid costly repairs. Do you know that clean oil improves performance and accuracy? It’s true! A simple oil check can make a big difference. Look for signs like discoloration or strange smells. These can signal it’s time for a change. Keeping your lathe in top shape means better projects and more success in your workshop.

Understanding the Role of Lathe Oil

Importance of lubrication in metal lathes. Types of lathe oil commonly used.

Lubrication is like a superhero for metal lathes, keeping them running smoothly. It helps parts move without getting stuck, like a slippery slide on a sunny day. Without proper oil, machines can wear out quickly. There are different types of lathe oil, and each has a special job. Here’s a handy table showing common oils:

| Type of Oil | Purpose |

|---|---|

| Mineral Oil | Basic lubrication for beginners. |

| Synthetic Oil | High performance for tough tasks. |

| Cutting Oil | Helps make clean cuts while machining. |

Using the right oil can make your lathe as happy as a pig in mud! Remember, a well-oiled lathe is a happy lathe!

Signs That It’s Time for an Oil Change

Indicators of oil degradation. Performance issues related to old oil.

Is your lathe showing some funky signs? Oil changes can be tricky, but don’t fret! Look for these clues. First, if the oil looks murky or smells funny, it’s time to say goodbye to that old stuff. Also, check for any odd noises from your machine. Performance issues, like slow operation, often mean the oil is past its prime. Don’t let old oil make your lathe sad; a happy lathe is a productive lathe!

| Sign | Action |

|---|---|

| Cloudy oil | Change it! |

| Strange sounds | Time for a refresh! |

| Slow performance | Oil change needed! |

Preparation for an Oil Change

Tools and materials needed for the process. Safety precautions to take before starting.

Getting ready for an oil change is like prepping for a school project—gather your tools and remember your safety gear! First, you’ll need some basic items. Don’t forget the lathe oil and a clean container for the old oil. A wrench and a funnel are helpful too. Safety goggles protect your eyes, and gloves keep your hands safe from slick stuff.

| Tools | Safety Gear |

|---|---|

| Lathe oil | Safety goggles |

| Wrench | Gloves |

| Container | |

| Funnel |

Make sure to work in a well-lit area. And, if your lathe starts whispering secrets, it’s time to pay attention! Safety first, because nobody wants an oil slip ‘n slide in the workshop!

Step-by-Step Guide to Changing Lathe Oil

Identifying the oil reservoir and drain locations. Detailed steps for draining old oil and refilling with new oil.

First, find the oil reservoir. This is usually near the machine’s motor. Then locate the drain plug, which sits at the bottom of the oil tank.

To change the oil, follow these steps:

- Turn off the lathe and allow it to cool.

- Place a container below the drain plug.

- Unscrew the drain plug and let old oil flow into the container.

- Once empty, close the drain plug tightly.

- Pour new oil into the reservoir until it’s full. Make sure to use the type recommended for your lathe.

Now, you’re good to go!

How often should I change lathe oil?

It’s best to change lathe oil every 3 to 6 months or after about 100 hours of use. Regular changes keep your lathe running smoothly and extend its life.

Maintaining Your Metal Lathe Pulley System

Recommended oil change frequency. Tips for prolonging oil life and maintaining lathe health.

To keep your metal lathe pulley system running smoothly, regular oil changes are key. Aim to change the oil every 30 to 50 hours of use. This helps keep the parts lubricated and prevents wear and tear. To prolong oil life and maintain the lathe’s health, follow these tips:

- Check oil levels weekly.

- Use clean containers for oil storage.

- Keep the lathe clean to prevent dust buildup.

- Inspect seals for leaks.

These simple steps can help your lathe last longer and work better!

How often should you change lathe oil?

The oil should be changed every 30 to 50 hours of operation. This keeps your lathe working fine!

Common Mistakes to Avoid During Oil Changes

Incorrect oil types that can harm your lathe. Overfilling and underfilling: consequences and solutions.

Changing oil in your lathe can be tricky. Using the wrong oil type is like trying to bake cookies with salt instead of sugar. It can ruin your machine. Stick to the manufacturer’s recommendations. Next, be careful with how much oil you add. Overfilling is like pouring too much soda into a glass—it spills everywhere! Underfilling? That’s like running on fumes! Both lead to trouble. So, check the level and avoid these common blunders!

| Error | Effect | Solution |

|---|---|---|

| Using Incorrect Oil | Can damage the lathe. | Follow the manual. |

| Overfilling | Causes leaks and mess. | Check the oil level. |

| Underfilling | May lead to poor performance. | Top it up properly. |

Final Checks After Changing Oil

Verifying proper lubrication. Testing the lathe functionality postmaintenance.

After changing the oil, it’s time for some fun checks. First, make sure the lathe is properly lubed. You don’t want it squeaking like a rusty door! Next, test the lathe to ensure it works smoothly. If it runs like a well-oiled machine, you’ve succeeded! Here’s a quick checklist:

| Check | Status |

|---|---|

| Lubrication | Verified |

| Functionality | Passed |

Remember, a happy lathe means a happy woodworker! If it squeaks, something might need another look. Don’t ignore the sounds; they can tell you secrets!

Conclusion

In conclusion, changing lathe oil is important for maintaining your metal lathe’s pulley. Fresh oil helps keep everything running smoothly. Remember to check the oil level regularly and replace it when needed. This simple step can save you time and improve your projects. You can learn more about lathe maintenance online or in books. Start taking care of your tools today!

FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Oil Change For A Metal Lathe Pulley:

Changing the lathe oil is important for keeping your metal lathe running smoothly. First, turn off the lathe and unplug it for safety. Next, find the drain plug and let the old oil drain out into a container. After that, refill the lathe with new oil until it’s at the right level. Finally, clean up any spills and check the oil level again after a few days of use.

Sure! Please let me know what question you would like me to answer.

What Type Of Oil Is Recommended For Lubricating The Pulleys On A Metal Lathe?

You should use light machine oil or 3-in-1 oil for the pulleys on a metal lathe. These oils are good for keeping moving parts smooth. Make sure to check the oil often and add more if needed. It’s important to keep everything well-lubricated to help the lathe work better.

How Often Should The Oil Be Changed In The Lathe’S Pulley System To Ensure Optimal Performance?

You should change the oil in the lathe’s pulley system every six months. If you use the lathe a lot, change it every three months. Fresh oil keeps everything running smoothly. Always check the oil level too. When in doubt, it’s better to change it more often!

What Steps Should Be Followed To Properly Change The Oil In A Metal Lathe Pulley?

To change the oil in a metal lathe pulley, first, turn off the lathe and unplug it for safety. Next, find the oil drain plug and place a container underneath it to catch the old oil. Unscrew the plug and let the oil drain out completely. Then, replace the plug and fill the pulley with new oil using the correct kind. Finally, clean any spills and plug the lathe back in to use it again.

Can Using The Wrong Type Of Lubricant Affect The Performance Of The Lathe Pulley?

Yes, using the wrong lubricant can cause problems with the lathe pulley. If the lubricant is too thick or too thin, it can make the pulley stick or move poorly. This can slow down your work and even damage the lathe. Always choose the right lubricant for the best results!

What Are The Signs That Indicate It’S Time To Change The Oil In A Metal Lathe Pulley?

You can tell it’s time to change the oil in a metal lathe pulley if you notice strange noises. If the pulley feels really hot to touch, that’s another sign. You might also see a lot of dirt or sludge in the oil. Finally, if the oil looks really dark or thick, it’s time for a change.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Oil Change For A Metal Lathe Pulley:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Changing the lathe oil is important for keeping your metal lathe running smoothly. First, turn off the lathe and unplug it for safety. Next, find the drain plug and let the old oil drain out into a container. After that, refill the lathe with new oil until it’s at the right level. Finally, clean up any spills and check the oil level again after a few days of use.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please let me know what question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Type Of Oil Is Recommended For Lubricating The Pulleys On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should use light machine oil or 3-in-1 oil for the pulleys on a metal lathe. These oils are good for keeping moving parts smooth. Make sure to check the oil often and add more if needed. It’s important to keep everything well-lubricated to help the lathe work better.”}},{“@type”: “Question”,”name”: “How Often Should The Oil Be Changed In The Lathe’S Pulley System To Ensure Optimal Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should change the oil in the lathe’s pulley system every six months. If you use the lathe a lot, change it every three months. Fresh oil keeps everything running smoothly. Always check the oil level too. When in doubt, it’s better to change it more often!”}},{“@type”: “Question”,”name”: “What Steps Should Be Followed To Properly Change The Oil In A Metal Lathe Pulley? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To change the oil in a metal lathe pulley, first, turn off the lathe and unplug it for safety. Next, find the oil drain plug and place a container underneath it to catch the old oil. Unscrew the plug and let the oil drain out completely. Then, replace the plug and fill the pulley with new oil using the correct kind. Finally, clean any spills and plug the lathe back in to use it again.”}},{“@type”: “Question”,”name”: “Can Using The Wrong Type Of Lubricant Affect The Performance Of The Lathe Pulley? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, using the wrong lubricant can cause problems with the lathe pulley. If the lubricant is too thick or too thin, it can make the pulley stick or move poorly. This can slow down your work and even damage the lathe. Always choose the right lubricant for the best results!”}},{“@type”: “Question”,”name”: “What Are The Signs That Indicate It’S Time To Change The Oil In A Metal Lathe Pulley? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can tell it’s time to change the oil in a metal lathe pulley if you notice strange noises. If the pulley feels really hot to touch, that’s another sign. You might also see a lot of dirt or sludge in the oil. Finally, if the oil looks really dark or thick, it’s time for a change.”}}]}