Have you ever wondered how to keep your metal lathe running smoothly? Changing the lathe oil is a simple yet important task. Just like changing oil in a car, it helps the lathe work better and last longer.

Imagine your lathe making strange noises or not cutting smoothly. That might be a sign it’s time for an oil change. But don’t worry! This article will walk you through the process, step by step.

Did you know that using the right oil can greatly affect your lathe’s performance? Just like a car, a metal lathe needs proper care. Learning how to change the lathe oil not only protects your investment but also boosts your confidence as a DIY enthusiast.

So, let’s dive in! By the end, you’ll see how easy it is to take care of your metal lathe stand and keep it in top shape.

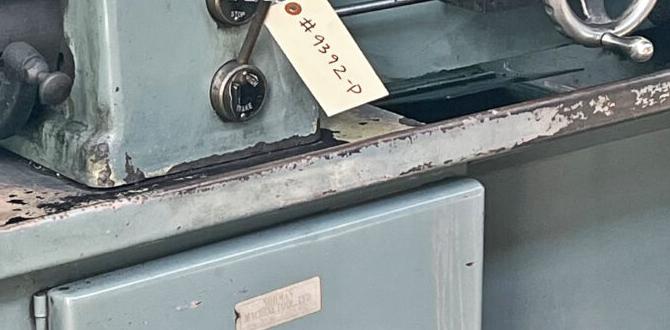

Essential Guide To Lathe Oil Change For Metal Lathe Stand

Lathe Oil Change for Metal Lathe Stand

Changing the oil in your metal lathe stand is crucial for smooth operation. It keeps the machine running quietly and efficiently. Regular oil changes can prevent rust and wear, saving you money on repairs. Did you know that dirty oil can create friction and heat? This can damage your lathe over time. Make a habit of checking oil levels and follow the manufacturer’s recommendations. Keeping your lathe happy means better projects for you!

Understanding Lathe Oil and Its Importance

Definition of lathe oil and its role in lubrication. Benefits of regular oil changes for metal lathes.

Lathe oil is a special type of oil designed to keep your metal lathe running smoothly. It helps reduce friction and wear between moving parts. When you change the oil regularly, you enjoy some important benefits:

- Improved performance of the lathe.

- Longer machine life.

- Less chance of breakdowns.

So, changing lathe oil is not just a chore. It helps ensure that your lathe works like new!

Why is changing lathe oil important?

It keeps machines healthy! Regular oil changes prevent parts from wearing out and help avoid costly repairs.

Signs Your Metal Lathe Needs an Oil Change

Common indicators of wornout oil. Consequences of neglecting oil changes.

Noticing some odd behavior from your metal lathe? It might be time for an oil change! Common signs include a gritty texture in the oil, a strange smell, or even an unexpected squeak. Ignoring these signs is like forgetting to feed your pet—bad things happen! Without fresh oil, your lathe could overheat or wear out faster. Keep your machine happy and running smoothly; it’s a small effort for big results!

| Signs of Worn-Out Oil | Consequences of Neglect |

|---|---|

| Gritty texture | Overheating |

| Strange odor | Increased wear |

| Unusual noises | Reduced efficiency |

Tools and Materials Needed for an Oil Change

Essential tools to have on hand. Required materials, including oil specifications and containers.

Changing oil in your metal lathe is important. You need the right tools and materials. Here are some essentials:

- Wrench set for removing bolts.

- Container to hold old oil.

- New lathe oil that meets specifications.

- Rags for cleaning spills.

- Funnel for easy pouring.

Having these items ready makes the job easier. Always check the oil type for your lathe. The right oil helps keep it running smoothly!

What tools are needed for an oil change?

You will need a wrench set, a container for old oil, and a funnel. These tools make the process simple and efficient.

Step-by-Step Guide to Changing Lathe Oil

Detailed instructions on draining old oil. How to properly clean and replace oil filters.

Changing your lathe oil is important for keeping it running smoothly. To drain the old oil, locate the drain plug under the machine. Unscrew it and let the oil flow into a container. It might take a few minutes. While it drains, clean the oil filter. A clean filter helps your lathe work better. Replace it after cleaning. Now, refill the lathe with new oil through the fill hole.

How do you know when to change lathe oil?

You can tell it’s time to change oil when it looks dark or dirty. Inspect it every few months for the best performance.

Quick Tips for a Successful Oil Change

- Always use the type of oil recommended by the manufacturer.

- Check for leaks after the oil change.

- Schedule regular maintenance to keep your lathe in top shape.

Best Practices for Maintenance After an Oil Change

Tips for ensuring optimal lathe performance. Recommended schedule for future oil changes.

Keeping your lathe in tip-top shape is crucial for smooth operations. After an oil change, check all moving parts to ensure everything is cleaned and lubricated properly. A little maintenance can prevent major headaches later! It’s best to change the oil every 100 hours of use to keep things running efficiently. Upgrade your routine by jotting down your oil change schedule in a handy table. It’s like giving your lathe a calendar for its spa days!

| Usage (Hours) | Oil Change Frequency |

|---|---|

| 0 – 100 | Change oil |

| 100 – 200 | Check oil level |

| 200+ | Change oil and inspect |

Common Mistakes to Avoid When Changing Lathe Oil

List of frequent errors and their implications. How to troubleshoot issues that may arise.

Changing lathe oil seems simple, but mistakes can happen. One common error is using the wrong type of oil. This can make your lathe feel like it’s running through molasses! Forgetting to clean the oil pan? That’s like baking cookies without washing the mixing bowl—yuck!

Another mistake is changing oil too rarely. If you wait too long, your lathe might just throw a temper tantrum. If issues pop up, check the oil level and look for leaks. Always consult your manual; it’s like a treasure map for your lathe!

| Error | Implications | Troubleshooting Tips |

|---|---|---|

| Wrong oil type | Sluggish performance | Check specifications |

| Neglecting to clean | Clogs and sludge | Clean the pan regularly |

| Infrequent changes | Higher wear and tear | Create a schedule |

Frequently Asked Questions About Lathe Oil Changes

Answers to common queries about oil change frequency and procedures. Suggestions for additional resources and support.

Wondering how often to change your lathe oil? Well, it’s usually good to do it every month or after around 50 hours of use. This helps keep your machine running smoothly and happy! As for how to change it, start by turning off the lathe and letting it cool down—no one wants a hot surprise! Then, drain the old oil and refill it with fresh stuff. Need more help? Check out online forums, manuals, or even YouTube tutorials. They can be a lifesaver when you’re unsure.

| Question | Answer |

|---|---|

| How often should I change lathe oil? | Every month or 50 hours of use. |

| What if I don’t have time? | Make time or risk a cranky lathe! |

| Where can I learn more? | Online resources and workshops are great! |

Conclusion

In conclusion, changing lathe oil is essential for your metal lathe’s performance. A clean lathe stand helps maintain stability and accuracy. You should check the oil regularly for the best results. Remember, a well-maintained lathe lasts longer and works better. Explore more on lathe care to keep your projects running smoothly. Happy turning!

FAQs

What Type Of Oil Is Recommended For Changing The Lathe Oil In A Metal Lathe Stand?

You should use machine oil or ISO grade 32 oil for your lathe. This oil helps the machine run smoothly. Make sure it’s clean and fresh when you change it. It keeps the parts from getting too hot or rusty. Always follow your lathe’s instructions for the best results.

How Often Should The Lathe Oil Be Changed To Ensure Optimal Performance Of A Metal Lathe?

You should change the lathe oil every few months. If you use the lathe a lot, change it more often. Check the oil regularly to see if it looks dirty or dark. Clean oil helps your lathe work better and last longer. Always follow the instructions in the lathe’s manual for best results.

What Are The Steps Involved In Changing The Lathe Oil In A Metal Lathe Stand?

To change the lathe oil, first, turn off the lathe and let it cool down. Next, find the drain plug and place a container under it. Open the drain plug to let the old oil flow out. When it’s empty, close the plug and fill the tank with new oil. Finally, check the oil level and clean up any spills.

Are There Any Specific Signs That Indicate It’S Time To Change The Lathe Oil?

Yes, there are signs that show it’s time to change the lathe oil. If the oil looks dark or dirty, it needs changing. You might also hear strange noises from the lathe. If the machine runs less smoothly, that’s another sign. Checking oil regularly helps keep your lathe working well.

Can Using The Wrong Type Of Oil Affect The Performance Or Lifespan Of A Metal Lathe?

Yes, using the wrong oil can hurt your metal lathe. It might not work well, and parts could wear out faster. This can lead to breaks and make your lathe last not as long. Always choose the right oil to keep it working great!