Have you ever felt the excitement of making something with your own hands? Many hobbyists love working with metal lathes. But do you know how important lathe oil is for these machines? Just like cars need oil changes for smooth rides, metal lathes need regular oil changes too.

Imagine your metal lathe running smoothly, creating perfect shapes every time. That’s the magic of keeping it well-oiled! An upgrade can make all the difference in performance.

So, why should we pay attention to lathe oil changes? Regularly changing the oil keeps your machine happy and healthy. It reduces wear and tear, extending its life. Plus, it ensures your projects turn out just right.

Think of your lathe as a friend. Would you let a friend run on empty? No! You’d fill them up with what they need. Let’s dive deeper into the world of lathe oil changes and see how they help you make the best of your metal lathe upgrades!

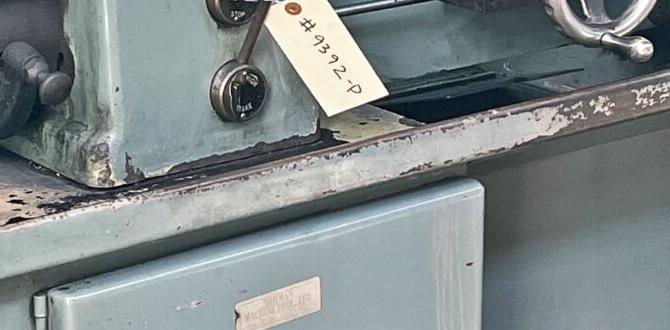

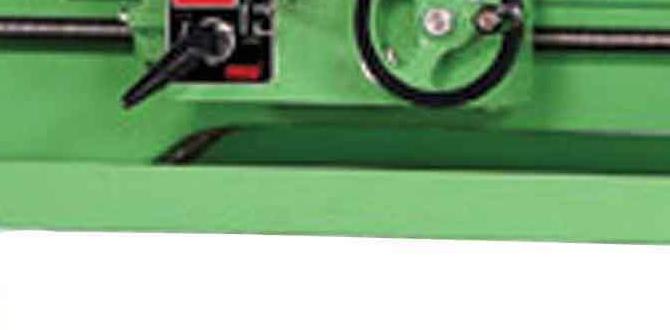

Essential Lathe Oil Change For Your Metal Lathe Upgrade

Lathe Oil Change Metal Lathe Upgrade

Changing lathe oil is crucial for smooth operation. Regular oil changes keep your machine healthy. Did you know that old oil can lead to wear and tear? Upgrading to a better oil makes a difference. It can improve performance and extend the lathe’s life. Proper maintenance encourages precision in your work. Imagine crafting a perfect piece every time. Investing time in oil changes is truly worthwhile for any metal lathe user. Keep your machine running like new!Understanding Lathe Oil and Its Importance

Definition and types of lathe oil. Role of lathe oil in machine performance and longevity.Lathe oil is a special lubricating oil used in metal lathes. It comes in various types, like sawing oil and cutting oil, each made for different tasks. This oil helps machines run smoothly by reducing friction and wear. Imagine trying to ride a rusty bike – not fun! With good lathe oil, machines stay healthy, which means they last longer. So, keep that oil topped up! It’s like giving your machine a refreshing drink after a long day of work.

| Type of Lathe Oil | Best For |

|---|---|

| Cutting Oil | Metal cutting processes |

| Sawing Oil | Sawing operations |

| General Purpose Oil | Lubrication for light tasks |

With the right lathe oil, you’ll keep your machine running like a well-oiled machine – literally!

Signs Your Lathe Needs an Oil Change

Common indicators of old or contaminated oil. Effects of neglecting timely oil changes on metal lathe functionality.It’s important to check your lathe oil regularly. Look for these signs that tell you it’s time for an oil change:

- Dark or cloudy oil

- Metal shavings mixed in

- Strange noises from the machine

If you ignore these signs, your metal lathe can face big problems. Old oil can lead to wear and tear. It affects precision and can even break parts. Regular oil changes keep your lathe running smoothly.

What are the signs your lathe needs an oil change?

Signs include dark oil, metal shavings, and strange noises from the lathe. Regular checks help catch problems early.

Choosing the Right Lathe Oil for Your Machine

Factors to consider when selecting lathe oil. Comparison of mineralbased and synthetic oils.Picking the right lathe oil isn’t as hard as it seems. Start by checking your lathe’s manual; it offers guidance for your machine’s needs. Another key point is viscosity – that’s a fancy word for thickness! You want oil that flows easily but isn’t too thin. Now, let’s talk options: mineral-based oils are good for basic tasks, while synthetic oils provide better performance and longer life. Think of it like choosing between a cozy blanket versus a space-age sleeping bag!

| Type of Oil | Pros | Cons |

|---|---|---|

| Mineral-based | Affordable, easy to find | Needs frequent changes |

| Synthetic | Lasts longer, resists heat | Costs more upfront |

So, whether you go with the classic or the cutting-edge, make sure it matches your lathe’s style and routine. It’s like giving your machine a snack—it needs the right fuel to keep running smoothly!

Step-by-Step Guide to Changing Lathe Oil

Tools and materials required for an oil change. Detailed procedure for draining and refilling oil.Before changing lathe oil, gather your tools and materials. You’ll need a wrench, a clean cloth, and your new oil. Don’t forget a proper container to catch the old oil! First, turn off the machine and let it cool down. Then, use the wrench to remove the drain plug and let the old oil flow out. While that’s draining, grab a snack—just not the oil! Finally, refill with fresh oil and replace the drain plug. Easy peasy!

| Tools | Materials |

|---|---|

| Wrench | New lathe oil |

| Clean cloth | Oil container |

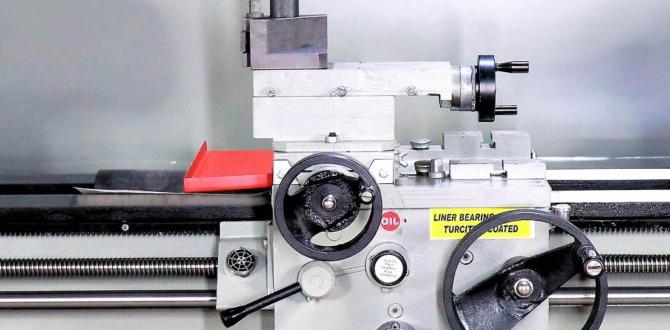

Upgrading Your Metal Lathe: Oil Change Considerations

How upgraded lathe components affect oil requirements. Tips for ensuring compatibility with new upgrades.Upgrading your metal lathe can be exciting! However, new parts can change how much oil you need. Upgraded components may need a different type of oil for best performance. Thick oil might slow things down, while thin oil could leak. Before you change your oil, check the manual to ensure compatibility with your new parts. Here are some tips to keep everything running smoothly:

| Tip | Description |

|---|---|

| Check Compatibility | Look up the right oil for your new parts. |

| Viscosity Matters | Choose oil that matches your lathe’s needs. |

| Stay Clean | Keep everything free of dust and debris! |

Remember, the right oil will keep your lathe happy. A happy lathe makes happy projects! Who knew oil could be so exciting?

Maintenance Tips for Optimal Lathe Performance

Regular oil change schedules and monitoring. Best practices for general lathe maintenance to prevent issues.Keeping your lathe in top shape is like giving it a cozy blanket! Start with regular oil changes every few months. Fresh oil keeps your metal lathe happy and running smoothly. Check the oil level often, too; it’s a bit like checking if your pet needs food. For general maintenance, make sure to clean the lathe regularly and tighten any loose parts. Remember, a little care goes a long way in preventing big problems. Here’s a handy table to help you keep track:

| Maintenance Task | Frequency |

|---|---|

| Oil Change | Every 3-6 months |

| Check Oil Level | Monthly |

| Clean Lathe | Weekly |

| Tighten Loose Parts | Monthly |

Happy lathing for a long time! Remember, a well-maintained lathe is a joyful lathe.

Frequently Asked Questions about Lathe Oil Changes

Common misconceptions about lathe oil. Clarifications on oil change frequency and procedures for different lathe models.Many folks believe that all lathe oils are the same. That’s as true as thinking all superheroes wear capes! Different lathe models require different oil types and change schedules. The general rule is to check your manual, as some lathes need oil changes every month while others can go for several months. Most importantly, don’t forget the oil filter! Keeping it clean helps your lathe run like a champ. Below is a quick guide:

| Lathe Model | Oil Change Frequency | Notes |

|---|---|---|

| Model A | Every month | Check filter too! |

| Model B | Every 3 months | Keep an eye on performance. |

| Model C | Every 6 months | Great for light usage. |

Confused? No need! Just remember: regular checks keep your lathe humming smoothly and can spare you from future headaches.

Conclusion

In conclusion, upgrading your metal lathe and changing its oil are key steps for better performance. Regular oil changes keep your machine running smoothly and extend its life. When you upgrade, consider features that will improve your work. So, dive into your lathe maintenance today! Explore more resources to enhance your skills and keep your tools in top shape.FAQs

Here Are Five Related Questions On The Topic Of Lathe Oil Changes And Metal Lathe Upgrades:Changing the oil in a lathe is important. It keeps the machine running smoothly and helps it last longer. You should check the oil regularly and change it if it looks dirty or thick. Upgrading your metal lathe can improve its power and precision, making your projects better. Always follow the manufacturer’s instructions for both oil changes and upgrades!

Sure! Just let me know what question you would like me to answer.

What Type Of Oil Is Recommended For Maintenance And Lubrication In Metal Lathes?For metal lathes, we usually use a special oil called way oil. It is thick and sticks to the parts. This oil helps the machine move smoothly. You can also use light machine oil for some parts. Always check the manual to be sure!

How Often Should Oil Changes Be Performed On A Metal Lathe To Ensure Optimal Performance?You should change the oil in a metal lathe every 50 to 100 hours of use. This helps keep the machine running smoothly. If you use it a lot, check the oil more often. Always look at the oil level and color too. Keeping it clean helps your lathe work better!

What Upgrades Can Be Made To A Metal Lathe To Improve Its Efficiency And Longevity?You can make several upgrades to your metal lathe. First, adding a better motor can make it faster. Next, using high-quality bearings helps parts move smoothly. You can also put on a digital readout for precise measurements. Lastly, keep it clean and lubricated to make it last longer.

Are There Specific Signs That Indicate It’S Time To Change The Oil In A Metal Lathe?Yes, there are signs that tell you it’s time to change the oil in a metal lathe. If the oil looks dirty or dark, it’s time for new oil. You might also notice strange noises when the lathe is running. If the machine feels hot or doesn’t work smoothly, that’s another sign. Always check the oil regularly to keep everything running well!

How Can Upgrading The Lubrication System In A Metal Lathe Impact Its Operational Efficiency?Upgrading the lubrication system in a metal lathe helps it work better. Better oil or grease keeps moving parts running smoothly. When parts don’t stick or wear out fast, we can make things faster and easier. This means less time fixing problems and more time creating things. Overall, it makes our work more efficient!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Oil Changes And Metal Lathe Upgrades:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Changing the oil in a lathe is important. It keeps the machine running smoothly and helps it last longer. You should check the oil regularly and change it if it looks dirty or thick. Upgrading your metal lathe can improve its power and precision, making your projects better. Always follow the manufacturer’s instructions for both oil changes and upgrades!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just let me know what question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Type Of Oil Is Recommended For Maintenance And Lubrication In Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For metal lathes, we usually use a special oil called way oil. It is thick and sticks to the parts. This oil helps the machine move smoothly. You can also use light machine oil for some parts. Always check the manual to be sure!”}},{“@type”: “Question”,”name”: “How Often Should Oil Changes Be Performed On A Metal Lathe To Ensure Optimal Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should change the oil in a metal lathe every 50 to 100 hours of use. This helps keep the machine running smoothly. If you use it a lot, check the oil more often. Always look at the oil level and color too. Keeping it clean helps your lathe work better!”}},{“@type”: “Question”,”name”: “What Upgrades Can Be Made To A Metal Lathe To Improve Its Efficiency And Longevity?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can make several upgrades to your metal lathe. First, adding a better motor can make it faster. Next, using high-quality bearings helps parts move smoothly. You can also put on a digital readout for precise measurements. Lastly, keep it clean and lubricated to make it last longer.”}},{“@type”: “Question”,”name”: “Are There Specific Signs That Indicate It’S Time To Change The Oil In A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there are signs that tell you it’s time to change the oil in a metal lathe. If the oil looks dirty or dark, it’s time for new oil. You might also notice strange noises when the lathe is running. If the machine feels hot or doesn’t work smoothly, that’s another sign. Always check the oil regularly to keep everything running well!”}},{“@type”: “Question”,”name”: “How Can Upgrading The Lubrication System In A Metal Lathe Impact Its Operational Efficiency?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Upgrading the lubrication system in a metal lathe helps it work better. Better oil or grease keeps moving parts running smoothly. When parts don’t stick or wear out fast, we can make things faster and easier. This means less time fixing problems and more time creating things. Overall, it makes our work more efficient!”}}]}