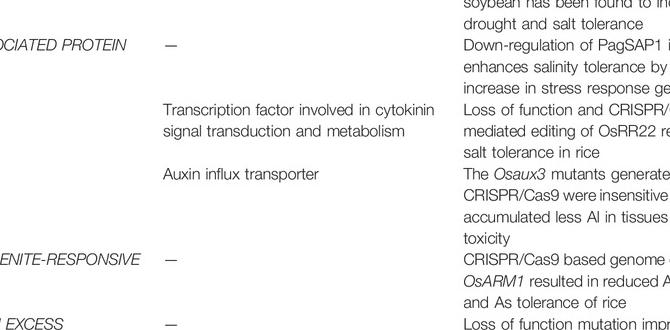

Have you ever wondered why some tools need oil changes? Imagine you have a metal lathe and a wood lathe. They both create amazing projects, but they have different needs. Just like cars need oil changes to run smoothly, these lathes need their own special care.

Today, we will explore the world of lathe oil changes. You might be surprised to learn how important oil is for your machines. Using the right oil keeps your projects safe and helps your lathes last longer. Are you curious about the differences between metal lathes and wood lathes? Let’s dive in!

Many makers don’t realize that the type of oil matters. For instance, metal lathes may need heavier oils compared to wood lathes. Why does this matter? Choosing the right oil can mean the difference between a smooth finish and a rough one!

Get ready to learn about lathe oil changes. Understanding these differences will help you care for your tools better. Your projects will thank you, and so will your lathes!

Lathe Oil Change: Metal Lathe Vs Wood Lathe Comparison

Lathe Oil Change: Metal Lathe vs. Wood Lathe

Lathe oil change is crucial for machine performance. Metal lathes need oil to prevent rust and wear, while wood lathes generally require lighter oil. Did you know that using the wrong oil can damage your equipment? It’s a common mistake! Regularly changing oil improves the lifespan of your lathe and helps it run smoothly. Understanding these differences can save you time and money in repairs. Always check your lathe’s manual for proper oil types and change intervals.Understanding Lathe Oil

Definition and purpose of lathe oil. Importance of lubrication in lathe performance.Lathe oil is a special liquid that helps machines work smoothly. Its main purpose is to reduce friction between moving parts. Good lubrication keeps your lathe in good shape. It helps parts move easily and stops them from getting too hot. This is important for both metal lathes and wood lathes, as it improves their performance.

- Reduces wear and tear

- Prevents rust and corrosion

- Improves accuracy of cuts

Why is lubrication important for lathe performance?

Lubrication is vital for long-lasting lathe equipment. It enhances performance by providing smooth movement and preventing damage.

When to Change Lathe Oil

Indicators for oil change in metal lathes. Indicators for oil change in wood lathes.Knowing when to change lathe oil is crucial for the machine’s health. For metal lathes, look for these signs:

- Strange noises during operation

- Oil color that is dark or murky

- Inconsistent movement or sticking parts

For wood lathes, keep an eye out for:

- A smoky smell while working

- Oil leaks from the machine

- Poor finish quality on wood pieces

Changing the oil at the right time can keep your lathe running smoothly!

How often should lathe oil be changed?

It’s best to change lathe oil every 50-100 hours of use. Regular checks can save you from bigger problems later.

Types of Lathe Oils

Recommended oils for metal lathes. Recommended oils for wood lathes.Choosing the right oil is important for a lathe’s performance. For metal lathes, oils like machine oil or motor oil work well. These oils reduce friction and keep the machine running smoothly. For wood lathes, using lighter oils like mineral oil or vegetable oil helps. These oils protect the wood and keep the lathe clean.

- Metal Lathes: Machine oil, motor oil

- Wood Lathes: Mineral oil, vegetable oil

What oils should be used for metal lathes?

Machine oil and motor oil are best for metal lathes. They help reduce wear and improve operation.

What oils are good for wood lathes?

Mineral oil and vegetable oil are great for wood lathes. They prevent damage and keep surfaces smooth.

Steps for Changing Oil in Metal Lathes

Tools required for oil change. Stepbystep process for changing oil.Ready to give your metal lathe a refreshing oil change? First, gather your tools. You’ll need an oil pump, a wrench, and some clean rags—don’t forget gloves; your hands aren’t fans of oil! Here’s a quick breakdown:

| Tool | Purpose |

|---|---|

| Oil Pump | To remove old oil |

| Wrench | To open the oil drain |

| Rags | To clean the mess |

| Gloves | To protect your hands |

Start by turning off the lathe and unplugging it. Next, use the wrench to open the drain plug and let the old oil flow out. Once it’s empty, replace the plug tightly. Now, grab that oil pump and inject fresh oil into the machine. Easy peasy! Clean up any spills, and voilà, your lathe is ready to spin again!

Steps for Changing Oil in Wood Lathes

Tools required for oil change. Stepbystep process for changing oil.Changing oil in your wood lathe keeps it running smoothly. To do this, you’ll need a few simple tools:

- Oil pan

- Wrenches

- New oil

- Rags

Follow these easy steps for a successful oil change:

- Turn off and unplug the lathe.

- Place an oil pan under the machine.

- Open the oil drain plug to let old oil flow out.

- Clean the drain plug and replace it.

- Pour in new oil until it reaches the right level.

- Seal everything up, and you’re done!

This simple process keeps your lathe happy and working well!

What tools do I need to change oil in a wood lathe?

You need a few basic items: an oil pan, wrenches, new oil, and rags. These tools help you change the oil easily and effectively.

Common Mistakes to Avoid

Misunderstanding oil types. Neglecting regular maintenance schedules.Avoiding some common mistakes can improve the life of your lathe. One mistake is misunderstanding oil types. Different lathes need specific oils. Using the wrong type can harm your machine. Also, neglecting regular maintenance is a big issue. Keeping a schedule helps catch problems early. Regular checks can save you time and money.

What are the common mistakes with lathe maintenance?

Common mistakes include using incorrect oil for your machine and skipping maintenance checks.

Benefits of Regular Oil Changes

Improved performance and longevity for metal lathes. Improved performance and longevity for wood lathes.Regular oil changes are like a superhero for lathes. They boost performance and help machines last longer. For metal lathes, good oil keeps parts smooth and running. This means fewer breaks and less downtime. It also makes work faster and easier.

Wood lathes benefit, too. Fresh oil helps blades cut cleanly. This means better-looking projects. It also reduces wear and tear on the machine.

- Metal lathes: Improved speed and reduced wear.

- Wood lathes: Sharper cuts and longer life.

Oil changes matter for all lathes. Treat your machine well, and it will treat you well!

Why are oil changes important for lathes?

Oil changes keep lathes running smoothly and help them last much longer.

FAQs about Lathe Oil Change

Common questions regarding oil types and change frequency. Clarifications on userspecific lathe requirements.Many people have questions about lathe oil changes. It’s important to know which oil to use and how often to change it. Here are some common inquiries:

What type of oil should I use for my lathe?

For most lathes, light machine oil works well. Metal lathes may need specific oils for better performance.

How often should I change the oil?

Many recommend changing oil every 50 hours of use. Check your lathe’s manual for exact advice.

Special considerations:

- Metal lathes need more frequent changes due to heavy wear.

- Wood lathes may run longer before needing oil changes.

Knowing the right oil and change frequency helps keep your lathe running smoothly. Regular maintenance is key to its lifespan.

Conclusion

In conclusion, changing lathe oil is essential for both metal and wood lathes. Metal lathes often use mineral oils, while wood lathes might benefit from lighter oils. Always check your manual for specific instructions. By maintaining your lathe, you’ll ensure it runs smoothly and lasts longer. For more tips, keep reading and explore related articles!FAQs

Here Are Five Related Questions On The Topic Of Lathe Oil Change For Metal Lathes Versus Wood Lathes:Metal lathes and wood lathes need oil to work well. You should change the oil based on how often you use them. Metal lathes usually need oil more often because they have metal parts that create friction. Wood lathes may require less oil since they mainly work with soft wood. Always follow the owner’s manual for the best advice.

Sure! Please provide the question you’d like me to answer.

What Type Of Oil Is Recommended For Maintaining A Metal Lathe Compared To A Wood Lathe?For a metal lathe, we should use machine oil or heavy-duty oil. This oil protects the metal parts and helps them move smoothly. For a wood lathe, you can use lighter oils or special wood lathe oil. These oils keep things running well but don’t need to be as thick. Always check the instructions for your lathe to see what it needs!

How Often Should The Oil Be Changed In A Metal Lathe Versus A Wood Lathe?You should change the oil in a metal lathe every 40 to 50 hours of use. For a wood lathe, you can change the oil less often, about every 100 hours. Metal lathes work harder and need more care. Always check the oil regularly to keep your lathe in good shape!

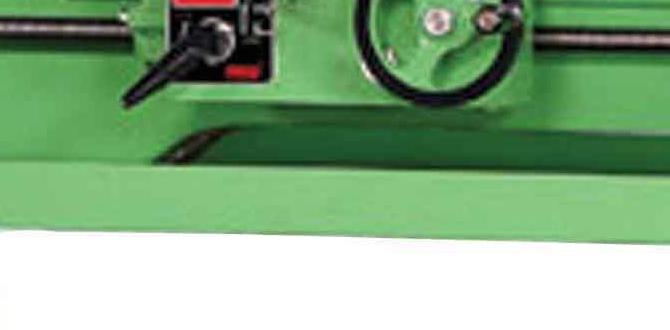

What Are The Specific Lubrication Points That Need Attention During An Oil Change For Each Type Of Lathe?When you change the oil in a lathe, you should pay attention to a few important spots. First, look at the spindle. This is where the chuck spins. Next, check the ways. These are the long, flat parts that help the lathe move smoothly. Don’t forget the carriage, which helps hold and move the tool. Lastly, add oil to the slideways, where parts slide against each other. This keeps everything running well!

Are There Any Differences In The Oil Change Process Or Tools Required For Metal Lathes Compared To Wood Lathes?Yes, there are some differences in changing oil for metal lathes and wood lathes. Metal lathes often need special oil for the machines to run smoothly. You usually use different tools to change the oil in each type. For wood lathes, you might not even need to change oil often. So, we should always follow the instructions specific to each lathe.

How Does The Operating Environment And Usage Patterns Of A Metal Lathe Differ From Those Of A Wood Lathe In Terms Of Lubrication Needs?A metal lathe works with heavy, strong materials, so it needs more lubrication. This helps keep it cool and reduces wear. We use oil for metal lathes, as it handles high heat. A wood lathe works with softer wood, needing less lubrication. Sometimes, a little wax can be enough for wood lathes.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Oil Change For Metal Lathes Versus Wood Lathes:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathes and wood lathes need oil to work well. You should change the oil based on how often you use them. Metal lathes usually need oil more often because they have metal parts that create friction. Wood lathes may require less oil since they mainly work with soft wood. Always follow the owner’s manual for the best advice.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Type Of Oil Is Recommended For Maintaining A Metal Lathe Compared To A Wood Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For a metal lathe, we should use machine oil or heavy-duty oil. This oil protects the metal parts and helps them move smoothly. For a wood lathe, you can use lighter oils or special wood lathe oil. These oils keep things running well but don’t need to be as thick. Always check the instructions for your lathe to see what it needs!”}},{“@type”: “Question”,”name”: “How Often Should The Oil Be Changed In A Metal Lathe Versus A Wood Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should change the oil in a metal lathe every 40 to 50 hours of use. For a wood lathe, you can change the oil less often, about every 100 hours. Metal lathes work harder and need more care. Always check the oil regularly to keep your lathe in good shape!”}},{“@type”: “Question”,”name”: “What Are The Specific Lubrication Points That Need Attention During An Oil Change For Each Type Of Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you change the oil in a lathe, you should pay attention to a few important spots. First, look at the spindle. This is where the chuck spins. Next, check the ways. These are the long, flat parts that help the lathe move smoothly. Don’t forget the carriage, which helps hold and move the tool. Lastly, add oil to the slideways, where parts slide against each other. This keeps everything running well!”}},{“@type”: “Question”,”name”: “Are There Any Differences In The Oil Change Process Or Tools Required For Metal Lathes Compared To Wood Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there are some differences in changing oil for metal lathes and wood lathes. Metal lathes often need special oil for the machines to run smoothly. You usually use different tools to change the oil in each type. For wood lathes, you might not even need to change oil often. So, we should always follow the instructions specific to each lathe.”}},{“@type”: “Question”,”name”: “How Does The Operating Environment And Usage Patterns Of A Metal Lathe Differ From Those Of A Wood Lathe In Terms Of Lubrication Needs?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe works with heavy, strong materials, so it needs more lubrication. This helps keep it cool and reduces wear. We use oil for metal lathes, as it handles high heat. A wood lathe works with softer wood, needing less lubrication. Sometimes, a little wax can be enough for wood lathes.”}}]}