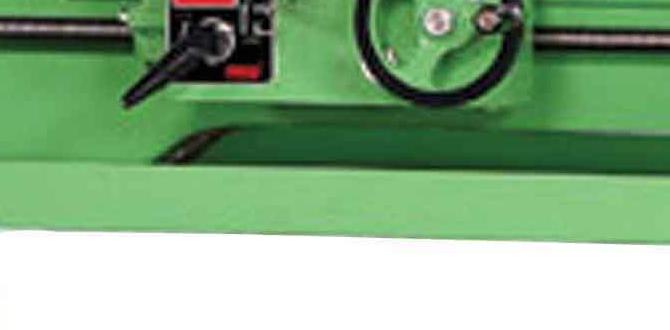

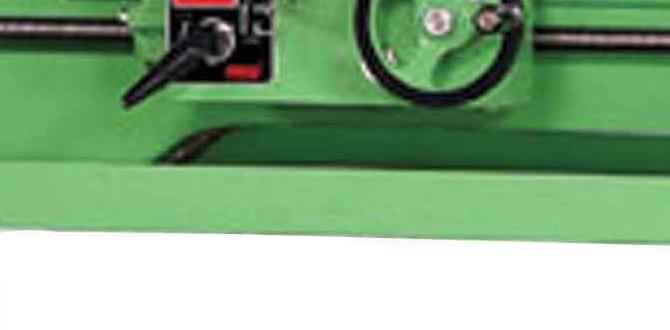

When was the last time you checked your lathe oil? Many people forget this important task. Keeping the oil fresh helps your metal lathe run smoothly and efficiently. Imagine being in the middle of a project when your lathe stops working. A simple oil change could have prevented that problem!

But how do you know when it’s time to change the oil? What if you’re unsure about your lathe’s wiring? Understanding these steps can make you a better metalworker. Everyone wants their tools to last longer and work better. That’s where a good lathe oil change and clear wiring diagram come into play.

Did you know that using the right oil can improve your lathe’s performance? Different machines need different oils. This means picking the right one can save you time and stress. In this article, we will dive into how to change your lathe oil and explore helpful wiring diagrams. By the end, you’ll be ready to tackle any lathe-related challenge!

Lathe Oil Change: Essential Metal Lathe Wiring Diagram Guide

Lathe Oil Change & Metal Lathe Wiring Diagram

Knowing when to change lathe oil is key for smooth operations. Regular oil changes can help your metal lathe last longer. Do you ever wonder how oil affects your machine’s performance? A well-maintained lathe runs better and cuts more accurately. Understanding wiring diagrams is essential for safety. They guide you in setting up your lathe correctly. Remember, good maintenance and clear diagrams protect your investment. Curious about how oil and wiring work together? You’ll find they are crucial for the best results!Importance of Regular Lathe Oil Changes

Benefits of lubrication in metal lathes. Effects of neglecting oil changes on lathe performance.Keeping your metal lathe well-oiled is like giving it a spa day! Regular oil changes help tools run smoothly. They prevent wear and tear, making your lathe last longer. If you skip oil changes, your lathe might act grumpy. It could start making funny noises or even stop working altogether. Remember, a happy lathe is a productive lathe!

| Oil Change Benefits | Neglect Effects |

|---|---|

| Reduces friction | Increased wear |

| Improves performance | Possible damage |

| Extends lifespan | Costly repairs |

So, keep that oil flowing and avoid turning your lathe into a museum piece!

Steps for Performing a Lathe Oil Change

Required tools and materials for oil change. Detailed stepbystep process for changing oil.Changing the oil in your lathe is crucial for keeping it running smoothly. First, gather your tools and materials. You’ll need an oil pan, a wrench, and, of course, some fresh lathe oil—because no one likes cranky machinery! Here’s a simple step-by-step guide:

| Step | Action |

|---|---|

| 1 | Switch off and unplug the lathe for safety. |

| 2 | Place the oil pan beneath the machine. |

| 3 | Use the wrench to drain old oil into the pan. |

| 4 | Pour in the new lathe oil. |

| 5 | Turn on the lathe for a quick check. |

Follow these steps, and you’ll have your lathe purring like a kitten in no time! Remember, a well-oiled lathe is a happy lathe!

Common Mistakes to Avoid During Oil Change

Typical errors made while changing lathe oil. Tips for ensuring effective oil maintenance.Changing lathe oil can be tricky. Many people make mistakes that lead to problems later. Here are some common errors:

- Not checking the oil type.

- Ignoring the oil level.

- Forgetting to clean the area before changing oil.

To keep your lathe running well, follow these tips:

- Use the right oil for your machine.

- Check levels regularly.

- Keep the work area tidy.

These steps help ensure effective oil maintenance. Remember, a little care goes a long way!

What is the right type of oil to use for my lathe?

The best oil depends on your lathe’s needs and specifications. Always refer to the manual for guidance.

Understanding Metal Lathe Wiring Diagrams

Explanation of key components in a lathe wiring diagram. Importance of proper wiring for safe operation.Metal lathe wiring diagrams are like treasure maps for your machine. They show you all the key parts, helping you understand what connects to what. Think of the main components: the motor, switch, and power supply. Each plays a big role in making sure everything runs smoothly and safely. Without proper wiring, your lathe can become a misbehaving metal monster! Remember, safe operation starts with correct wiring and perhaps a little less coffee!

| Component | Function |

|---|---|

| Motor | Powers the lathe |

| Switch | Controls power |

| Power Supply | Provides energy |

How to Read a Metal Lathe Wiring Diagram

Breakdown of symbols and notations used in wiring diagrams. Tips for tracing wires and diagnosing issues.Understanding a wiring diagram for a metal lathe is important. Symbols on these diagrams show different parts, like motors and switches. Here’s a simple breakdown:

- Circles: represent connection points.

- Lines: show how wires connect.

- Arrows: indicate power flow direction.

To trace wires, follow them from start to finish. If something isn’t working, look for breaks or loose connections. This helps you find issues faster and keep your lathe running smoothly.

What are common symbols in metal lathe wiring diagrams?

Common symbols include circles for junction points, lines for wire paths, and arrows showing electricity flow.

Troubleshooting Wiring Issues in Metal Lathes

Common electrical problems in lathes. How to approach troubleshooting wiring failures.Metal lathes can face many common electrical problems. You might see issues like:

- Poor connections.

- Broken wires.

- Faulty switches.

Troubleshooting these wiring failures starts with checking the basics. First, look for loose wires. Make sure everything is securely connected. Next, see if any wires are damaged. If they are, replace them carefully. If problems persist, inspect switches and circuits. Using a wiring diagram can help you understand where issues may lie.

What are some common electrical problems in metal lathes?

Common electrical problems include faulty circuits, damaged wires, and poor connections.

How to approach troubleshooting wiring failures?

Start by checking for loose connections and damaged wires. Use a wiring diagram for guidance.

Best Practices for Lathe Maintenance

Routine checks and maintenance tasks beyond oil changes. Importance of keeping wiring in good condition.Keeping your lathe in top shape means doing more than changing oil. Regular routine checks are important. Make sure to inspect belts, gears, and any moving parts. This helps prevent sudden breakdowns. Also, keeping wiring in good condition is crucial. Frayed wires can cause shorts or fires. Check for any damage often to stay safe.

- Inspect belts for wear

- Verify gears are lubricated

- Check wiring for any damage

- Keep components clean

How often should I check my lathe?

Check your lathe at least once a month. Regular checks keep everything working smoothly and safely.

Resources for Further Learning

Recommended manuals and guides for lathe maintenance. Online forums and communities for lathe enthusiasts.Learning about lathe maintenance can be fun! There are many fantastic manuals that will help you understand lathe oil changes and wiring diagrams. Grab a guide, and you’ll feel like a pro. Don’t forget online forums where fellow lathe lovers share tips and tricks. You can ask questions or even share your funny stories about your lathe adventures! Here’s a quick look at some helpful resources:

| Type | Resource |

|---|---|

| Manuals | Machinery’s Handbook |

| Online Forum | Lathe Lovers Community |

| Guide | The Complete Guide to Metalworking |

Conclusion

In conclusion, understanding lathe oil changes and metal lathe wiring diagrams is essential for maintaining your lathe. Regular oil changes keep your machine running smoothly. Meanwhile, knowing the wiring diagram helps you troubleshoot issues effectively. We encourage you to explore more about these topics. You can also read manuals or watch videos to enhance your skills further. Happy machining!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Oil Change And Metal Lathe Wiring Diagrams:Sure! Here are five questions about changing lathe oil and wiring diagrams for a metal lathe: 1. **Why do we change lathe oil?** We change lathe oil to keep the machine working well. Fresh oil helps it run smoothly. 2. **How often should you change the oil?** You should change the oil regularly, like every few months or when the lathe feels rough. 3. **What is a wiring diagram?** A wiring diagram shows how the wires connect inside the lathe. It helps us fix or set up the machine. 4. **Can I read a wiring diagram alone?** Yes! You can learn to read a wiring diagram with practice. Just take your time to understand it. 5. **What tools do I need for an oil change?** You need a wrench, a container for old oil, and fresh lathe oil. These tools help you do the job right.

Sure! Just let me know what question you’d like me to answer.

What Type Of Oil Is Recommended For Changing The Oil In A Metal Lathe, And How Often Should It Be Changed?For a metal lathe, you should use a good-quality machine oil. This helps the lathe run smoothly. You should change the oil every 6 months or more often if you use the lathe a lot. Always check the oil level and color. If it looks dirty, it’s time to change it!

How Do You Properly Locate And Access The Oil Reservoir On A Typical Metal Lathe During An Oil Change?To find the oil reservoir on a metal lathe, look for a small tank or opening usually near the bottom. You might see a cap or a plug there. Use a wrench to carefully remove the cap or plug. Once it’s open, you can drain the old oil. Remember to put everything back neatly after you finish!

Can You Provide A Step-By-Step Guide On How To Execute An Oil Change For A Metal Lathe, Including Any Safety Precautions?Sure! Here’s how to change the oil on a metal lathe. 1. First, unplug the lathe for safety. 2. Put on safety glasses and gloves. 3. Find the oil drain plug under the lathe. 4. Use a container to catch the old oil when you remove the plug. 5. Let all the old oil drain out. 6. Replace the drain plug securely. 7. Open the oil fill cap and pour in new oil. 8. Close the fill cap tightly. Remember to clean up any spills!

What Are The Common Electrical Components In A Metal Lathe Wiring Diagram, And How Do They Interact With The Oil Lubrication System?In a metal lathe wiring diagram, we usually see parts like the motor, switches, and sensors. The motor helps the lathe move and cut metal. The switches let you turn the machine on and off. Some sensors check if there’s enough oil in the lubrication system to keep parts running smoothly. If there isn’t enough oil, the sensors can warn you, helping to prevent damage.

How Can I Troubleshoot Electrical Issues In A Metal Lathe If The Wiring Diagram Indicates A Problem With The Oil Pump Or Related Components?To troubleshoot the electrical problem in your metal lathe, first, turn off the power. Next, check the oil pump for any loose wires or damage. Make sure it’s connected firmly to the power supply. You can also test the pump with a multimeter to see if it’s working. If you find a broken part, you may need to replace it to fix the issue.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Oil Change And Metal Lathe Wiring Diagrams:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about changing lathe oil and wiring diagrams for a metal lathe: 1. **Why do we change lathe oil?** We change lathe oil to keep the machine working well. Fresh oil helps it run smoothly. 2. **How often should you change the oil?** You should change the oil regularly, like every few months or when the lathe feels rough. 3. **What is a wiring diagram?** A wiring diagram shows how the wires connect inside the lathe. It helps us fix or set up the machine. 4. **Can I read a wiring diagram alone?** Yes! You can learn to read a wiring diagram with practice. Just take your time to understand it. 5. **What tools do I need for an oil change?** You need a wrench, a container for old oil, and fresh lathe oil. These tools help you do the job right.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just let me know what question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Type Of Oil Is Recommended For Changing The Oil In A Metal Lathe, And How Often Should It Be Changed?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For a metal lathe, you should use a good-quality machine oil. This helps the lathe run smoothly. You should change the oil every 6 months or more often if you use the lathe a lot. Always check the oil level and color. If it looks dirty, it’s time to change it!”}},{“@type”: “Question”,”name”: “How Do You Properly Locate And Access The Oil Reservoir On A Typical Metal Lathe During An Oil Change?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the oil reservoir on a metal lathe, look for a small tank or opening usually near the bottom. You might see a cap or a plug there. Use a wrench to carefully remove the cap or plug. Once it’s open, you can drain the old oil. Remember to put everything back neatly after you finish!”}},{“@type”: “Question”,”name”: “Can You Provide A Step-By-Step Guide On How To Execute An Oil Change For A Metal Lathe, Including Any Safety Precautions?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here’s how to change the oil on a metal lathe. 1. First, unplug the lathe for safety. 2. Put on safety glasses and gloves. 3. Find the oil drain plug under the lathe. 4. Use a container to catch the old oil when you remove the plug. 5. Let all the old oil drain out. 6. Replace the drain plug securely. 7. Open the oil fill cap and pour in new oil. 8. Close the fill cap tightly. Remember to clean up any spills!”}},{“@type”: “Question”,”name”: “What Are The Common Electrical Components In A Metal Lathe Wiring Diagram, And How Do They Interact With The Oil Lubrication System?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In a metal lathe wiring diagram, we usually see parts like the motor, switches, and sensors. The motor helps the lathe move and cut metal. The switches let you turn the machine on and off. Some sensors check if there’s enough oil in the lubrication system to keep parts running smoothly. If there isn’t enough oil, the sensors can warn you, helping to prevent damage.”}},{“@type”: “Question”,”name”: “How Can I Troubleshoot Electrical Issues In A Metal Lathe If The Wiring Diagram Indicates A Problem With The Oil Pump Or Related Components?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To troubleshoot the electrical problem in your metal lathe, first, turn off the power. Next, check the oil pump for any loose wires or damage. Make sure it’s connected firmly to the power supply. You can also test the pump with a multimeter to see if it’s working. If you find a broken part, you may need to replace it to fix the issue.”}}]}