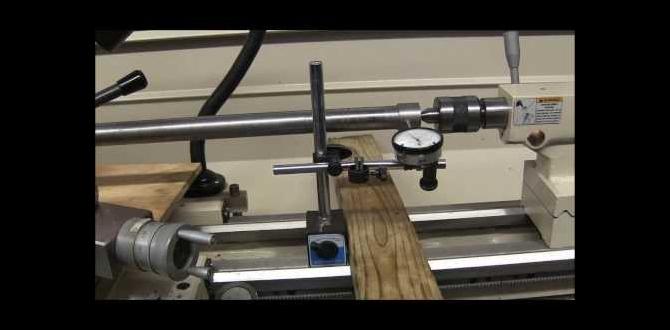

Have you ever wondered how a small machine can make big things? A mini metal lathe is like a superhero for metalworking. It helps you shape, cut, and finish metal with ease. But did you know that keeping it in top shape requires regular maintenance?

One important task is the lathe oil change. Just like your bicycle needs oil for smooth rides, your lathe also needs it to work well. Using fresh oil helps the machine run better and last longer. Brainstorming about how to keep your lathe healthy is key to great projects.

Imagine your lathe suddenly stops while you’re creating something amazing. Frustrating, right? Simple tasks like changing the oil can prevent that. A smooth-running lathe means more time for fun and less time fixing problems. So, let’s dive into how to do a lathe oil change on your mini metal lathe!

Lathe Oil Change For Mini Metal Lathe: Essential Guide

Lathe Oil Change for Mini Metal Lathes

Regularly changing lathe oil is essential for your mini metal lathe’s health. Did you know that fresh oil keeps the machine running smoothly? It reduces friction and wear, helping parts last longer. To change the oil, drain the old oil completely, clean the reservoir, and fill it with new oil. This simple task can save you from costly repairs. Keep your mini lathe in top shape with proper oil changes!Importance of Regular Oil Changes

Benefits of maintaining proper lubrication. Impact on machine longevity and performance.Changing oil regularly keeps your lathe running smoothly. Proper lubrication protects moving parts. This helps the machine last longer and work better. Think of oil as the lifeblood of your lathe. Without it, wear and tear can happen quickly. Here are some important benefits:

- Improved performance

- Less friction

- Longer machine life

Keep an eye on oil levels. A little attention goes a long way in keeping your tools effective.

Why is proper lubrication important?

Proper lubrication is crucial for reducing wear and tear on your machine. It helps all parts move smoothly, preventing damage and maintenance costs.

Tools and Materials Needed for an Oil Change

Essential tools for the oil change process. Recommended oil brands and types.Changing lathe oil is simple with the right tools. You need a few essentials to get started. Here’s a quick list:

- Oil change pump

- Drain pan

- Wrenches

- New oil

- Cloth or rag

For oil, look for high-quality brands. Some popular choices include:

- Mobil 1 Synthetic

- Clarity Synthetic

- Super Tech Oil

Choose oil based on your machine’s needs. Always check your lathe’s manual for the best type!

What tools are needed for an oil change?

You’ll need some simple tools. Wrenches, a pump, and a drain pan are essential for this task.

Step-by-Step Guide to Changing Oil in Mini Metal Lathes

Detailed instructions on preparing the lathe for oil change. Procedure for draining old oil and adding new oil.Changing the oil in your mini metal lathe is a breeze if you follow these steps. First, prepare by turning off the lathe and unplugging it. This way, it won’t spin like a whirlwind! Next, place a container under the oil pan. Drain the old oil carefully and watch it flow. It’s like feeding a giant metal baby! Once drained, add fresh oil through the fill port. Make sure it’s the right type—no extra spices, please!

| Steps | Actions |

|---|---|

| 1. Turn off and unplug | Safety first! |

| 2. Position the container | Catch the old oil like a pro! |

| 3. Drain the old oil | Let it flow! |

| 4. Add new oil | Fill it up, but don’t drown it! |

Common Mistakes to Avoid

Incorrect oil selection for specific lathe models. Neglecting oil levels and their impact on machine function.Choosing the wrong oil for your lathe can cause big problems. Different lathe models need specific oils. Always check your machine’s manual for the right choice.

Also, keeping an eye on the oil levels is crucial. When levels are low, the machine can get damaged or not work well. Regular checks can save you time and money in the long run.

What happens if I use the wrong oil?

Using the wrong oil can damage your lathe. It might not work properly and could even break down. Always pick the right oil for your lathe model!

Tips to remember:

- Check your lathe model’s manual.

- Inspect oil levels regularly.

- Refill oil before it runs low.

Signs Your Mini Metal Lathe Needs an Oil Change

Identifying performance issues related to lubrication. Recommended oil change frequency based on usage.Ever felt like your mini metal lathe is moving slower than a turtle in molasses? That could mean it’s time for an oil change! If you hear odd noises or notice rough movements, it’s a clear sign you need better lubrication. Experts suggest changing the oil every 50 hours of use, or sooner if you’re carving out masterpieces daily. Remember, a well-oiled lathe runs smoother, like butter on warm toast. Check out the table below for a simple guide:

| Usage | Oil Change Frequency |

|---|---|

| Light Use | Every 100 hours |

| Moderate Use | Every 50 hours |

| Heavy Use | Every 25 hours |

Maintaining Your Mini Metal Lathe Beyond Oil Changes

Additional maintenance tips for lathe care. Importance of periodic inspections and cleaning.Keeping your mini metal lathe happy means more than just changing the oil. Think of it like a pet; it needs love and attention! Regular cleaning is key to keeping dirt and shavings away. Check for wear and tear now and then. It’s like a health check-up for your lathe. Remember, a clean lathe runs smoother, just like a clean room helps you find your things faster! You wouldn’t want to lose your favorite toy in a mess, right?

| Maintenance Tips | Importance |

|---|---|

| Periodically clean the surface | Prevents rust and buildup |

| Inspect belts and bearings | Ensures smooth operation |

| Lubricate moving parts | Reduces wear and tear |

Your lathe deserves periodic pampering. This way, it’ll serve you longer and could even help you showcase your woodworking skills. After all, who wouldn’t want their workshop to be the talk of the town?

Conclusion

In summary, changing lathe oil in your mini metal lathe is essential for smooth operation. Regular oil changes keep your machine clean and efficient. It’s easy to do and improves the lifespan of your lathe. We encourage you to check your oil often and follow the manufacturer’s guidelines. For more tips, read up on lathe maintenance to enhance your skills!FAQs

Sure! Here Are Five Related Questions On The Topic Of Changing Lathe Oil In A Mini Metal Lathe:Sure! When you change lathe oil in a mini metal lathe, you need to turn off the machine first. Use a wrench to open the oil drain. Let the old oil flow out, then close the drain. Now, pour in fresh oil until it reaches the correct level. Don’t forget to clean up any spills!

Sure! Please provide the question you’d like me to answer.

What Type Of Oil Is Recommended For Lubricating A Mini Metal Lathe?You should use light machine oil to lubricate a mini metal lathe. This oil helps the parts move smoothly. You can also use a special oil designed for tool machines. Make sure to apply the oil to moving parts regularly. This keeps your lathe working well!

How Often Should I Change The Oil In My Mini Metal Lathe?You should change the oil in your mini metal lathe every 50 to 100 hours of use. If you use it a lot, change it more often. Old oil can get dirty and won’t protect the machine well. Checking the oil every month is a good idea too. Keeping it clean helps your lathe work better!

What Are The Steps Involved In Changing The Oil On A Mini Metal Lathe?To change the oil on a mini metal lathe, you first find the oil drain plug. Then, place a container under it to catch the old oil. Next, unscrew the plug and let the oil flow out. After the oil is empty, screw the plug back on. Finally, pour in new oil through the fill hole until it’s full.

Are There Specific Signs That Indicate It’S Time To Change The Lathe Oil?Yes, there are signs that show it’s time to change the lathe oil. First, if the oil looks dirty or has a dark color, it needs changing. Second, if you hear strange noises from the lathe, the oil may be old. Last, if the machine is running slower than usual, fresh oil can help it work better. Always check the oil regularly to keep your lathe healthy!

How Can Improper Oil Maintenance Affect The Performance And Longevity Of A Mini Metal Lathe?If you don’t take care of the oil in a mini metal lathe, it can get dirty or dry out. This makes the machine work harder and can cause parts to wear out faster. When that happens, the lathe may not cut metal well anymore. Keeping the oil clean and full helps the lathe last longer and work better.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Changing Lathe Oil In A Mini Metal Lathe:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! When you change lathe oil in a mini metal lathe, you need to turn off the machine first. Use a wrench to open the oil drain. Let the old oil flow out, then close the drain. Now, pour in fresh oil until it reaches the correct level. Don’t forget to clean up any spills!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Type Of Oil Is Recommended For Lubricating A Mini Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should use light machine oil to lubricate a mini metal lathe. This oil helps the parts move smoothly. You can also use a special oil designed for tool machines. Make sure to apply the oil to moving parts regularly. This keeps your lathe working well!”}},{“@type”: “Question”,”name”: “How Often Should I Change The Oil In My Mini Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should change the oil in your mini metal lathe every 50 to 100 hours of use. If you use it a lot, change it more often. Old oil can get dirty and won’t protect the machine well. Checking the oil every month is a good idea too. Keeping it clean helps your lathe work better!”}},{“@type”: “Question”,”name”: “What Are The Steps Involved In Changing The Oil On A Mini Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To change the oil on a mini metal lathe, you first find the oil drain plug. Then, place a container under it to catch the old oil. Next, unscrew the plug and let the oil flow out. After the oil is empty, screw the plug back on. Finally, pour in new oil through the fill hole until it’s full.”}},{“@type”: “Question”,”name”: “Are There Specific Signs That Indicate It’S Time To Change The Lathe Oil?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there are signs that show it’s time to change the lathe oil. First, if the oil looks dirty or has a dark color, it needs changing. Second, if you hear strange noises from the lathe, the oil may be old. Last, if the machine is running slower than usual, fresh oil can help it work better. Always check the oil regularly to keep your lathe healthy!”}},{“@type”: “Question”,”name”: “How Can Improper Oil Maintenance Affect The Performance And Longevity Of A Mini Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If you don’t take care of the oil in a mini metal lathe, it can get dirty or dry out. This makes the machine work harder and can cause parts to wear out faster. When that happens, the lathe may not cut metal well anymore. Keeping the oil clean and full helps the lathe last longer and work better.”}}]}