Have you ever wondered how metal pieces are shaped into useful tools or beautiful art? The magic often happens on a metal lathe. One key tool on this machine is the lathe parting tool. This little tool does big work by cutting through metal with ease.

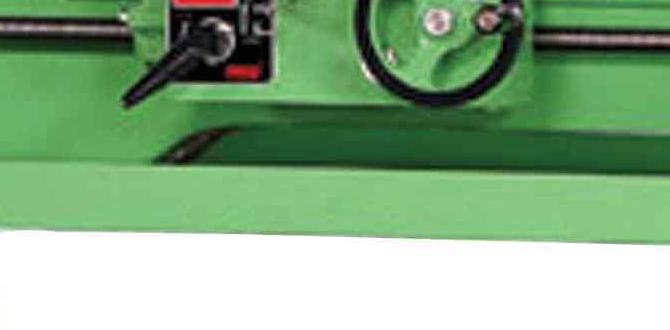

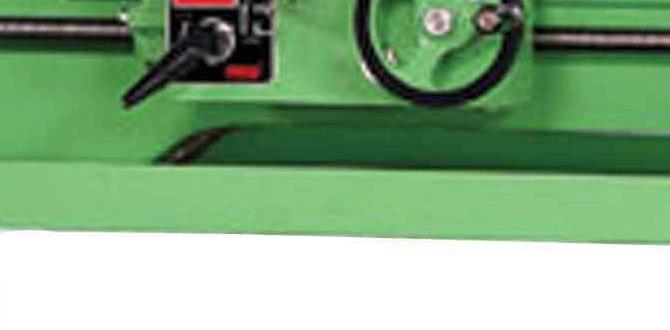

Imagine a project where you need a perfect shape for something special. The lathe parting tool helps you create that shape with precision. It attaches to the metal lathe bed, allowing it to slice through metal smoothly. But how does this simple tool make such a difference in a workshop?

Fun fact: The parting tool can cut deeper than most tools! It makes clean edges, so your projects look professional.

In this article, we will explore the lathe parting tool and its role on the metal lathe bed. Get ready to learn how this essential tool can make your metalworking easier and more enjoyable!

Essential Guide To Lathe Parting Tool For Metal Lathe Bed

Understanding the Lathe Parting Tool for Metal Lathe Beds

A lathe parting tool is essential for metalworking. It helps cut metal pieces cleanly without leaving rough edges. Imagine making a perfect shape from a block of metal—this tool achieves just that! The tool attaches to the lathe bed, a sturdy base where the magic happens. Knowing how to use these tools can improve your metalworking skills immensely. Did you know that using the right parting tool can save you time and materials?

Understanding Lathe Parting Tools

Definition and purpose of parting tools. Common features and specifications.

Parting tools are special cutting tools used on lathes. They help create deep grooves and cut off parts of metal. Think of them as the scissors for metalworking! Their main job is to separate material neatly without fuss. Most parting tools have a thin, flat blade that goes right into the material. This makes it easier to cut through. Here’s a quick look at some common features:

| Feature | Description |

|---|---|

| Blade Width | Usually ranges from 0.040″ to 0.125″. |

| Material | Typically made of high-speed steel or carbide. |

| Angle | Commonly set at 7 to 30 degrees for easy cutting. |

Now, when working with these tools, remember to keep your fingers clear! Safety first, right? Who knew metalwork could be a tiny bit dangerous? You cut, you groove, you smile!

Types of Parting Tools for Metal Lathes

Different materials used (HSS, Carbide, etc.). Profiles and designs suited for various applications.

Parting tools come in different flavors, just like ice cream! You can find them made from High-Speed Steel (HSS) or Carbide. HSS is tough and works well for lighter jobs, while carbide is like the superhero of the group, perfect for heavy-duty tasks. Additionally, parting tools have various profiles and designs, making them fit for any shape you can think of. Want to make something round? There’s a tool for that! Need something straight? They’ve got you covered too!

| Material | Best For |

|---|---|

| High-Speed Steel (HSS) | Light to medium work |

| Carbide | Heavy-duty work |

Choosing the Right Parting Tool for Your Metal Lathe

Factors to consider (material, thickness, and workpiece type). Comparing tool designs and their applications.

Choosing the right parting tool impacts your work with a metal lathe. First, consider the material of the tool. Different materials suit different jobs. Next, think about thickness. Thicker materials need stronger tools. Also, consider the workpiece type. Softer metals require lighter tools.

Compare tool designs based on these factors. Here are some common types:

- HSS (High-Speed Steel): Great for most tasks.

- Carbide: Best for tough materials.

- Indexable: Good for quick changes.

Finding the right tool makes your projects easier and more precise!

What factors should I consider for a parting tool?

Consider material, thickness, and workpiece type. Each factor affects tool performance.

Why is tool design important?

Different designs serve specific purposes. Using the right one can improve speed and accuracy.

How to Properly Use a Parting Tool

Stepbystep guidance on setup and operation. Best practices for maintaining accuracy and efficiency.

To use a parting tool correctly, start by setting it up on the lathe. Position it close to the workpiece. Make sure everything is stable. Now, begin the lathe. Move the parting tool steadily forward. Avoid rushing to keep accuracy high. Remember these best practices:

- Check your tool’s sharpness often.

- Adjust the speed for better cuts.

- Use steady pressure while cutting.

This will help you create clean and precise parts. A well-used tool leads to better results!

What are some common tips for using a parting tool?

Maintain a sharp edge, keep a steady hand, and ensure the lathe is running at the right speed for best results.

Maintaining Your Lathe Parting Tool

Cleaning and sharpening techniques. Storage guidelines to prolong tool life.

Keeping your lathe parting tool in tip-top shape is key to making great projects. Start by cleaning it after each use. Use a brush to remove chips, and a damp cloth to wipe off the metal. Want a sharp edge? Use a sharpening stone or file. Store your tool in a dry place, away from moisture. A tool box is great, but remember to wrap it in a cloth to keep it scratch-free. After all, a happy tool makes for happy work!

| Maintenance Task | Tip |

|---|---|

| Cleaning | Brush off chips & wipe with a damp cloth |

| Sharpening | Use a sharpening stone or file |

| Storage | Keep dry and wrap in cloth |

Enhancing Your Metal Lathe Experience with Accessories

Essential accessories to use with parting tools. How these accessories can improve performance.

Using the right accessories can make your metal lathe experience smoother and more fun. Have you ever tried a good coolant system? It keeps your tools cool and helps prevent damage. Additionally, using a solid tool holder ensures your parting tools stay steady. This means less chatter, more accuracy, and sure beats chasing your tools around like a cat chasing a laser pointer!

| Accessory | Benefit |

|---|---|

| Coolant System | Keeps tools cool and extends their life. |

| Tool Holder | Improves stability and accuracy. |

| Indexable Inserts | Offers multiple cutting edges for longer use. |

These simple tools can boost your lathe’s performance and keep things interesting in the shop. Who knew woodworking could come with so many cool gadgets?

Real-Life Applications of Parting Tools in Metalworking

Case studies and projects highlighting successful usage. Feedback from experienced machinists on tool performance.

Parting tools are superheroes in metalworking! They help machinists create neat, clean cuts. In one project, a group of students built custom metal brackets using a parting tool. They achieved perfect results, and their teacher said it was like “magic.” Experienced machinists rave about how these tools save time and produce better pieces. Feedback often mentions how parting tools keep things organized and less messy, which makes everyone happy!

| Machinist | Project | Feedback |

|---|---|---|

| John Smith | Metal Brackets | “Best cuts I’ve ever made!” |

| Linda Lee | Parts for a Robot | “Less mess equals more success!” |

Conclusion

In summary, a lathe parting tool is important for cutting grooves and shaping metal. The metal lathe bed provides stability and precision in your work. Understanding these tools helps you create better projects. If you’re ready to learn more, consider reading guides or watching videos on using lathes. You can improve your skills and enjoy metalworking even more!

FAQs

Here Are Five Related Questions On The Topic Of Lathe Parting Tools And Metal Lathe Beds:

Lathe parting tools are special tools that help cut materials on a lathe. You use them to separate pieces from a larger one. They look like small, flat blades. Metal lathe beds are the long, flat surfaces where the machine sits. They keep everything steady while you work.

Sure! Just give me the question you’d like me to answer.

What Are The Key Features To Consider When Selecting A Parting Tool For A Metal Lathe?

When choosing a parting tool for a metal lathe, you should think about the size first. Make sure it fits your lathe. Next, look at the shape. A sharp edge works better for cutting. Also, consider the material. Strong materials last longer and cut better. Finally, check the handle. It should be comfortable for you to hold.

How Can The Design Of A Metal Lathe Bed Affect The Performance And Accuracy Of Parting Operations?

The design of a metal lathe bed can make a big difference in how well we can cut pieces. A strong and flat bed helps keep the tool steady. When the tool doesn’t wobble, it cuts more accurately. If the bed is too weak or uneven, it can make cuts messy. So, a good bed helps us do better work.

What Materials Are Commonly Used For Parting Tools, And How Do They Influence The Tool’S Durability And Effectiveness On A Lathe?

Parting tools are often made from high-speed steel or carbide. High-speed steel is strong and can be sharpened easily. Carbide is harder and lasts longer but can be more expensive. The material you choose affects how long the tool lasts and how well it cuts. Stronger materials help your tool cut better and stay sharp longer.

How Do You Properly Set Up And Align A Parting Tool In A Metal Lathe To Ensure Optimal Cutting Performance?

To set up a parting tool in a metal lathe, first, make sure the tool is sharp and clean. Put the tool in the tool holder, then tighten it securely. Next, position the tool so it lines up straight with the piece you’re cutting. You want it at the same height as the center of the workpiece. Finally, slowly turn on the lathe and make sure everything works smoothly.

What Maintenance Practices Should Be Followed To Keep A Metal Lathe Bed And Parting Tools In Good Working Condition?

To keep a metal lathe bed and parting tools in good shape, start by cleaning them regularly. Use a soft cloth to wipe off dust and grease. Check for rust and remove it with a gentle scrub using a rust remover. Make sure everything is well oiled to keep it moving smoothly. Always store your tools properly when you’re done working.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Parting Tools And Metal Lathe Beds:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe parting tools are special tools that help cut materials on a lathe. You use them to separate pieces from a larger one. They look like small, flat blades. Metal lathe beds are the long, flat surfaces where the machine sits. They keep everything steady while you work.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just give me the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Features To Consider When Selecting A Parting Tool For A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a parting tool for a metal lathe, you should think about the size first. Make sure it fits your lathe. Next, look at the shape. A sharp edge works better for cutting. Also, consider the material. Strong materials last longer and cut better. Finally, check the handle. It should be comfortable for you to hold.”}},{“@type”: “Question”,”name”: “How Can The Design Of A Metal Lathe Bed Affect The Performance And Accuracy Of Parting Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The design of a metal lathe bed can make a big difference in how well we can cut pieces. A strong and flat bed helps keep the tool steady. When the tool doesn’t wobble, it cuts more accurately. If the bed is too weak or uneven, it can make cuts messy. So, a good bed helps us do better work.”}},{“@type”: “Question”,”name”: “What Materials Are Commonly Used For Parting Tools, And How Do They Influence The Tool’S Durability And Effectiveness On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Parting tools are often made from high-speed steel or carbide. High-speed steel is strong and can be sharpened easily. Carbide is harder and lasts longer but can be more expensive. The material you choose affects how long the tool lasts and how well it cuts. Stronger materials help your tool cut better and stay sharp longer.”}},{“@type”: “Question”,”name”: “How Do You Properly Set Up And Align A Parting Tool In A Metal Lathe To Ensure Optimal Cutting Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a parting tool in a metal lathe, first, make sure the tool is sharp and clean. Put the tool in the tool holder, then tighten it securely. Next, position the tool so it lines up straight with the piece you’re cutting. You want it at the same height as the center of the workpiece. Finally, slowly turn on the lathe and make sure everything works smoothly.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Should Be Followed To Keep A Metal Lathe Bed And Parting Tools In Good Working Condition?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a metal lathe bed and parting tools in good shape, start by cleaning them regularly. Use a soft cloth to wipe off dust and grease. Check for rust and remove it with a gentle scrub using a rust remover. Make sure everything is well oiled to keep it moving smoothly. Always store your tools properly when you’re done working.”}}]}