Have you ever watched a lathe in action? It spins, cuts, and shapes metal into beautiful parts. One important tool in the lathe’s toolbox is the parting tool. It helps the machine cut through materials efficiently, making it easier to create precise pieces. But what if you could make your old metal lathe even better?

With a CNC retrofit, you can! This upgrade turns your manual lathe into a smart machine. Imagine having the power to make complex cuts with just a few clicks. Sounds amazing, right? So, what is this CNC retrofit all about?

This article will explore how a lathe parting tool works and how a CNC retrofit can breathe new life into your metal lathe. You’ll discover fun facts and tips to help you understand the magic of these machines. Get ready to dive into the world of metalworking and uncover how these tools can unlock your creativity!

Lathe Parting Tool For Metal Lathe Cnc Retrofit Projects

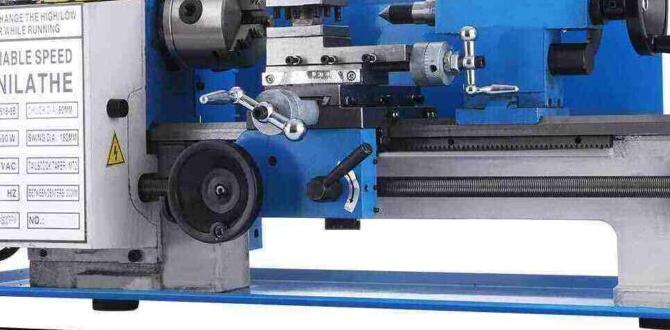

Lathe Parting Tool for Metal Lathe CNC Retrofit

Lathe parting tools are essential for cutting and shaping metal. They help in creating clean, precise edges. When retrofitting a CNC lathe, choosing the right parting tool can boost performance. Imagine using a tool that enhances your machine’s efficiency, making your projects smoother. Many hobbyists and professionals find these tools improve their craftsmanship. Did you know that using the right parting tool can save you time and reduce waste? Upgrade your lathe today for better results!Understanding Lathe Parting Tools

Definition and purpose of parting tools in metal lathes. Types of parting tools: standard vs. specialized.Lathe parting tools play a key role in shaping metal. They are used to cut materials into smaller pieces. Parting tools help create grooves or separate parts. There are two main types: standard and specialized. Standard tools work well for most jobs. Specialized tools serve unique needs or specific materials.

- Standard tools: Used for general cutting.

- Specialized tools: Designed for specific tasks, like cutting hard metals.

What are lathe parting tools used for?

Parting tools are used to cut through materials on a lathe, allowing for precise shaping and dividing of metal objects.

Importance of Parting Tools in CNC Retrofits

Role of parting tools in enhancing productivity. Benefits of integrating parting tools in CNC lathe systems.Parting tools are like superheroes for CNC retrofits! They carve out the shapes we need quickly and efficiently. This speeds up production, so you can make more parts in less time. Adding a parting tool to your CNC lathe can enhance both quality and speed. Need proof? Studies show that using these tools can increase productivity by up to 50%. That’s like finding an extra slice of pizza at a party! Integrating parting tools helps create clean cuts and reduces waste, making everyone happy in the workshop.

| Benefit | Description |

|---|---|

| Increased Efficiency | Speeds up production time significantly. |

| Improved Quality | Produces clean, precise cuts. |

| Less Waste | Minimizes material waste during production. |

Choosing the Right Parting Tool for Your CNC Lathe

Factors to consider: material, tool geometry, and application. Recommended brands and models for different projects.Selecting the right parting tool for your CNC lathe can be a bit like choosing ice cream flavors at a shop—there are so many tasty options! First, think about the material. Tools made from high-speed steel (HSS) are great for beginners, while carbide is tougher and lasts longer. Next, consider tool geometry. A sharp, angled tip can make cutting smoother. Lastly, think about your application. Different projects need different tools. You wouldn’t use a hammer to hang a picture, right?

| Brand | Model | Best For |

|---|---|---|

| Garr Tool | Parting Tool Set | General Use |

| Accu-Cut | CNC Parting Tool | Precision Cuts |

| Shars Tool | Carbide Insert Tool | Heavy Duty |

Whether you are a novice or a pro, picking the right parting tool is key. Remember, fun and learning can go hand in hand, so don’t forget to enjoy the process!

Setting Up Your Lathe for Parting Operations

Stepbystep guide to adjusting machine settings. Key adjustments for optimal performance and tool life.Getting your lathe ready for parting operations is important for good results. Start by checking the machine’s settings. Make sure the speed is correct. Adjust the feed rate for smooth cutting. Key changes include:

- Set the spindle speed between 200 – 600 RPM.

- Adjust the tool height so it’s level with the workpiece.

- Choose the right cutting tool for the material.

These adjustments help the tool last longer and improve your work’s quality.

Tips for Optimal Performance

Use proper lubrication to reduce friction and wear on your tools.- Check tool sharpness regularly.

- Keep the workspace clean.

These small steps can make a big difference!

Techniques for Effective Parting in CNC Machining

Best practices for parting operations. Common mistakes to avoid when using parting tools.Parting tools can be tricky little buddies in CNC machining. First, use the right speed. Too fast, and it’s like an angry blender—things can fly everywhere! Next, check your tool geometry. Make sure it’s sharp and happy. A dull tool is like a sleepy sloth; it just won’t get the job done. Watch out for common goofs too. Don’t push too hard or you might make your part go *poof*! Keep your coolant flowing; dry cuts are no fun. Remember, safety first!

| Error Type | Tip |

|---|---|

| Excessive Speed | Start slow; then find what works best. |

| Dull Tool | Keep it sharp for a smooth cut! |

| No Coolant | Always keep it cool and oiled. |

These simple tips will make your parting game better. Follow them and avoid those “uh-oh” moments!

Maintenance Tips for Longevity of Parting Tools

Regular maintenance routines and cleaning. Signs of wear and when to replace your parting tools.Keeping your parting tools in good shape is easy with some simple steps. Regularly cleaning tools can help them last longer. Wipe them with a soft cloth after use. Look for signs of wear like chips or dull edges. If your tools start to struggle, it may be time for a change. Remember these tips:

- Clean after each use.

- Check for chips or cracks.

- Replace if they are dull or damaged.

What are signs to replace parting tools?

Watch for dull cutting edges or visible damage. If your tool struggles to cut, it might be time for a new one. Keeping an eye on these signs helps you work better.

Case Studies: Successful CNC Retrofits Utilizing Parting Tools

Example projects showcasing improved efficiency and output. Lessons learned and strategies for successful implementation.Many companies have upgraded their machines, seeing great results. For example, a local shop improved production by using a lathe parting tool. They cut down setup time by 30%. Employees enjoyed the faster process too. Here are some lessons learned:

- Plan carefully before starting the retrofit.

- Train staff on new tools and methods.

- Monitor production closely after changes.

With these steps, businesses can boost efficiency and output. A smart strategy can turn any retrofitted lathe into a powerhouse.

What are the benefits of CNC retrofits?

CNC retrofits enhance precision and speed. They make machines more versatile and can significantly reduce waste. This often leads to higher profits for businesses.

Conclusion

In summary, a lathe parting tool is essential for metal lathes, especially during CNC retrofits. It helps you cut precise shapes easily. Understanding how to use this tool can improve your projects. We encourage you to explore more resources or tutorials to sharpen your skills. Practicing with a lathe will boost your confidence and creativity in metalworking.FAQs

What Are The Key Features To Look For In A Parting Tool For Use With A Cnc Retrofitted Metal Lathe?When choosing a parting tool for your CNC lathe, you should look for a few important features. First, the tool should be very sharp. This helps it cut through metal easily. Next, it should have a strong and sturdy design so it lasts longer. You also want a size that fits your lathe well. Lastly, the material should be tough, like high-speed steel or carbide, for better cutting.

How Can I Optimize The Settings Of A Cnc Retrofit To Improve The Performance Of My Lathe Parting Tool?To optimize your CNC retrofit for the lathe parting tool, start by adjusting the speed of the tool. Faster speeds can cut better, so try different speeds to see what works best. You should also check the tool’s feed rate, which is how fast the tool moves through the material. A good feed rate helps the tool cut smoothly. Lastly, make sure the tool is sharp and clean for the best performance.

What Material Properties Should I Consider When Selecting A Parting Tool For Machining Different Types Of Metal?When choosing a parting tool for cutting metal, you should think about hardness, toughness, and heat resistance. Hardness means how tough the tool is against wear. Toughness tells you if the tool can handle strong forces without breaking. Heat resistance helps the tool stay sharp when it gets hot from cutting. Each metal type might need a different tool based on these properties.

How Can Tooling Geometry And Cutting Angles Influence The Efficiency And Accuracy Of Parting Operations On A Cnc Lathe?Tooling geometry and cutting angles are like the shapes and angles of scissors. If we use the right shapes, the CNC lathe cuts better and faster. Good cutting angles let the tool slice through metal smoothly. This means we get accurate parts without mistakes. So, using the best tools helps us make things quickly and correctly!

What Are Common Challenges Faced During The Parting Process In Cnc Retrofitted Lathes, And How Can They Be Mitigated?During the parting process on CNC retrofitted lathes, you might face some challenges. One common problem is tool chatter, which makes a noisy vibration. You can fix this by using sharper tools and adjusting speeds. Another issue is tool wear, where the cutting tool gets dull quickly. You can change tools often and use the right type for your material.