Have you ever wondered how metal parts get perfectly shaped? Amazing tools called lathe parting tools make that happen. These tools cut and shape metal on a machine called a lathe. But that’s not all! What really makes them work well is a metal lathe controller. This device helps in controlling the process precisely.

Picture this: you are in a workshop, surrounded by different tools. Suddenly, you see someone using a lathe. Sparks fly as the parting tool slices through metal effortlessly. Isn’t that cool? With the right controller, anyone can create impressive metal designs.

Did you know that mastering these tools can lead to incredible creations? From tiny screws to big machine parts, lathe parting tools and controllers play key roles. They help makers and inventors bring their ideas to life.

Let’s dive into the world of lathe parting tools and discover how a metal lathe controller can change your metalworking game!

Lathe Parting Tool: Mastering Metal Lathe Controller Techniques

Understanding Lathe Parting Tools and Metal Lathe Controllers

Did you know a lathe parting tool can make precise cuts in metal? This tool helps separate material from a lathe efficiently and cleanly. Learning about metal lathe controllers is important too. They manage the speed and movements of the lathe. With good control, you can create smooth finishes and great shapes. Whether you are a hobbyist or a pro, mastering these tools makes your projects easier and more enjoyable.Understanding Lathe Parting Tools

Definition and purpose of parting tools in metalworking. Different types of parting tools available for metal lathes.Parting tools are important in metalworking. They help separate or cut materials into smaller pieces. This makes them useful for creating different shapes or sizes. There are various types of parting tools designed for metal lathes, including:

- Thin blade parting tools

- Grooving tools

- Heavy-duty parting tools

Each type serves a specific purpose. Choosing the right one is key for efficient metalwork.

What are common uses for parting tools?

Parting tools are often used for cutting metal pieces and creating grooves. These tasks are essential in many projects, from making machine parts to crafting jewelry.

Selecting the Right Parting Tool for Your Metal Lathe

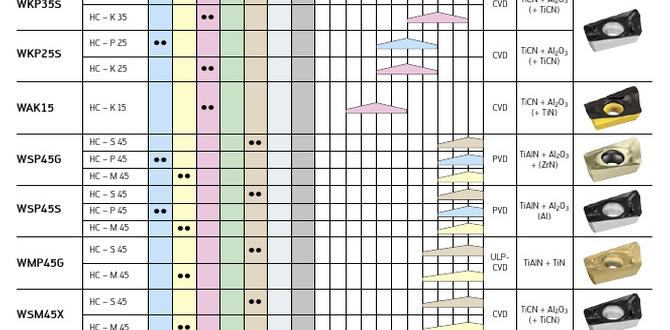

Key factors to consider when choosing a parting tool. Material compatibility and cutting edge geometry.Choosing the right parting tool for your metal lathe can feel like finding a needle in a haystack, but it doesn’t have to be a headache! Start by checking material compatibility. Make sure your tool matches the metal you’re working with. Next, look at the cutting edge geometry. A sharper edge can make a world of difference! Here’s a quick table to guide your selection:

| Material Type | Recommended Cutting Edge |

|---|---|

| Steel | High-speed steel (HSS) |

| Aluminum | Carbide |

| Copper | HSS with a sharper edge |

So, check your materials and pick a tool with a geometry that cuts smoothly. Happy lathing!

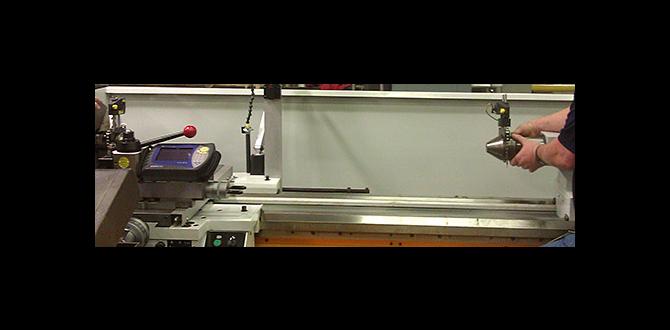

Setting Up Your Metal Lathe Controller for Parting Operations

Stepbystep guide to configuring your metal lathe controller. Important settings and adjustments for optimal parting performance.Getting your metal lathe controller ready for parting work is simpler than it sounds! First, check the speed setting—too fast and you’ll have more shavings than you can handle. Next, look at the feed rate; aim for a steady pace to avoid a wobbly cut. Adjust the depth of cut carefully—it’s better to go slow than to end up with a lopsided part. Stick to these steps, and you’ll part like a pro!

| Step | Action |

|---|---|

| 1 | Set the speed |

| 2 | Adjust the feed rate |

| 3 | Modify the depth of cut |

Techniques for Effective Parting with a Metal Lathe

Best practices for achieving clean cuts and minimizing tool wear. Troubleshooting common issues encountered during parting.To get nice, neat cuts with a metal lathe, you need to keep a few tricks up your sleeve. First, keep your tool sharp! Dull tools can make your cuts messy and can make you feel like you’re wrestling an octopus. Adjust your speed and feed rate to find the sweet spot—too fast could mean trouble, too slow may lead to a dull blade. If you notice chatter or vibrations, lower the speed and increase the feed. It’s like dancing; you want a smooth groove! Here’s a handy table for quick tips:

| Issue | Solution |

|---|---|

| Chatter | Lower speed, increase feed |

| Dull Tool | Sharpen regularly |

| Rough Cut | Check alignment and tool angle |

Following these tips will make your parting process smoother and keep your tools happy! Remember, a happy lathe is a productive lathe!

Maintenance Tips for Longevity of Parting Tools

Recommended cleaning and storage practices. Signs that indicate when to sharpen or replace your parting tool.To keep your parting tools in great shape, clean them regularly. Use a soft cloth to remove grime after each use. Store them in a dry place to prevent rust. Look out for signs to sharpen or replace your tool. If it feels dull or leaves rough edges, it’s time to sharpen. A chipped edge means it’s best to replace the tool altogether. Taking these steps can ensure your tools last longer.

How do I know when to sharpen my parting tool?

If your tool stops cutting smoothly or makes rough edges, it’s time to sharpen it.

Signs your parting tool needs attention:

- Feeling dull while working

- Visible chips on the edge

- Producing poor cut quality

Advanced Parting Strategies for Precision Machining

Utilizing CNC controls for enhanced accuracy in parting. Exploring custom parting tool designs for unique applications.Using CNC controls makes parting smoother than a butter slide. These advanced tools help create precise cuts by carefully guiding each tool movement. Imagine having a superpower that makes your cuts as sharp as your uncle’s one-liners at family gatherings! Custom parting tools add extra fun to the mix. Each design can tackle unique tasks, almost like superheroes in the machining world. Check out the nifty table below for a glimpse of these amazing parts:

| Tool Type | Application |

|---|---|

| Standard Parting Tool | General use for most metals |

| Grooving Tool | Creating grooves for better fits |

| Custom Tool | Special tasks tailored just for you |

With all these options, precision machining levels up like a video game character! So grab your lathe and start slicing with style!

Common Mistakes to Avoid When Using Parting Tools

Identifying common errors and their impacts on workpieces. Preventative measures to ensure successful parting operations.Using parting tools can be tricky. Many people make mistakes that hurt their work. Here are some common errors to watch for:

- Not aligning the tool correctly. This can lead to uneven cuts.

- Using too much pressure. This may cause tool breakage.

- Ignoring tool wear. A dull tool makes poor cuts.

To avoid these issues, follow these tips:

- Always check your tool alignment.

- Use steady, gentle pressure.

- Regularly inspect and replace worn tools.

Good practices make successful parting easier. Protect your work and tools by staying aware of these mistakes.

What should I consider when choosing a parting tool?

Choosing a parting tool involves checking the width, material, and cutting angle. These factors affect how well the tool performs. Consider the type of metal you are working with for better results.

Conclusion

In conclusion, a lathe parting tool is essential for cutting metal accurately. A metal lathe controller helps you operate the machine efficiently. Together, they make creating precise parts easier and faster. If you’re interested in metalworking, try using these tools in your projects. Read more about how to use them, and watch your skills grow!FAQs

Here Are Five Related Questions On The Topic Of Lathe Parting Tools And Metal Lathe Controllers:Lathe parting tools are special tools used on a machine called a lathe. They help cut materials into smaller pieces. We use them when we want to create shapes like disks or rings. Metal lathe controllers make it easier to control how the lathe works. They help us set the speed and direction for cutting safely and accurately.

Sure! Please provide the question you’d like me to answer.

What Are The Key Features To Look For In A Lathe Controller When Setting Up For Parting Operations?When setting up a lathe for parting operations, you want a controller that is easy to use. Look for a simple display that shows your settings clearly. You should also find options for speed control so you can adjust how fast the tool spins. A good controller lets you save your settings to use them again later. Lastly, check for safety features that will help prevent accidents while you work.

How Do Different Materials Used In Parting Tools Affect The Performance And Longevity Of The Tool During Metal Lathe Operations?The materials used in parting tools can change how well they work. Harder materials last longer and cut better. Softer materials can wear out quickly but are easier to shape. Choosing the right material helps you get clean cuts and makes the tool last. It’s like using a strong pair of scissors versus weak ones—you want the best to get good results!

What Techniques Can Be Utilized To Achieve A Clean And Accurate Cut When Using A Parting Tool On A Metal Lathe?To get a clean cut with a parting tool on a metal lathe, you should keep the tool sharp. Make sure to set the tool at the right angle against the metal. Go slowly and steady while cutting. It’s also a good idea to use some cutting oil to make the cut smoother. Finally, always wear safety gear, like goggles, to protect your eyes.

How Can Programmable Features In Modern Lathe Controllers Enhance The Efficiency Of Parting Operations?Programmable features in modern lathe controllers help you make parts faster and easier. You can set the machine to do the same steps over and over, so you don’t have to do it by hand. This saves time and helps make parts more accurate. You can also change settings quickly for different tasks. Overall, it makes parting operations smoother and helps you work better.

What Safety Precautions Should Be Observed When Using A Parting Tool On A Metal Lathe To Prevent Accidents And Tool Damage?When using a parting tool on a metal lathe, make sure to wear safety glasses to protect your eyes. Keep your hands away from the spinning part and never wear loose clothing that can get caught. Always check that the tool is secured before starting the lathe. Listen carefully for any strange sounds, and stop the machine if you hear them. Finally, never leave the lathe running unattended.