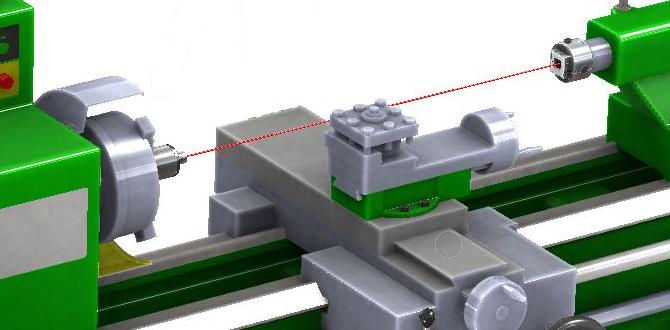

Have you ever watched a metal lathe in action? It’s fascinating to see how metal can be shaped with precision. At the heart of this process is the lathe parting tool. This tool plays a crucial role in cutting and shaping metal. But what makes it so special?

The lathe parting tool is designed to slice through metal smoothly. Imagine trying to cut a cake with a dull knife. It’s tough, right? Now picture using a sharp one. That’s the difference a good cutting tool makes!

In the world of metal lathes, having the right cutting tools is vital. They help create everything from intricate designs to simple shapes. Think about it: without these tools, many metal parts we use every day wouldn’t exist!

So, what exactly do you need to know about lathe parting tools? Get ready to dive deeper into the world of metal cutting. You might just discover your next favorite project!

Lathe Parting Tool: Essential Metal Lathe Cutting Tools

Understanding Lathe Parting Tools

Lathe parting tools are essential metal lathe cutting tools. They help create clean and precise cuts on metal pieces. Using these tools can save time and effort in machining projects. Ever tried cutting metal and ended up with rough edges? A good parting tool can solve that problem. Did you know the right parting tool can significantly improve your work quality? They come in various shapes and sizes, so you can find one that suits your needs. Happy machining!What is a Lathe Parting Tool?

Explanation of lathe parting tool and its function. Key components and design elements.A lathe parting tool is a special cutting tool used on a metal lathe. It helps to cut or “part” materials into smaller pieces. This tool has a sharp edge, usually shaped like a triangle. Key parts include:

- Blade: The sharp part that does the cutting.

- Shank: The handle that fits into the lathe.

- Point: The tip that guides the cut.

The design of this tool is simple yet effective. It allows for precise cuts, making it essential in metalworking. Without it, creating clean edges would be very difficult.

What is the main function of a lathe parting tool?

The main function of a lathe parting tool is to create a clean cut in metal pieces. This helps separate parts easily. Without this tool, making accurate cuts would be nearly impossible.

Choosing the Right Parting Tool for Your Metal Lathe

Factors to consider (material, width, and depth). How to match tools to specific projects.Selecting the best lathe parting tool is quite important. Several factors help in making the right choice. First, think about the material you need. Hard materials require tougher tools. Next, look at the width. A wider tool can make bigger cuts, while a narrow one is for detailed tasks. Finally, consider the depth of your cuts. Match your tool to your project for the best results. This careful selection leads to smoother work and better finished pieces.

What should I consider when choosing a parting tool?

Consider the material, width, and depth of your projects.Key Factors:

- Material: Match tool strength to material hardness.

- Width: Choose based on the cut size needed.

- Depth: Ensure the tool can manage the cut depth.

How to Use a Parting Tool Effectively

Stepbystep guide on operating a lathe parting tool. Common techniques for achieving precision cuts.Using a parting tool can be a fun challenge! First, securely mount your metal lathe parting tool. Next, adjust the tool rest to the right height. Remember, it should be level with the center of the lathe. Start slowly by engaging the tool into the workpiece. It’s like trying to fit into your favorite pair of jeans – go easy! For precision cuts, use a steady feed rate and let the tool do the work. Don’t rush; after all, good things come to those who wait!

| Step | Action |

|---|---|

| 1 | Mount the tool securely. |

| 2 | Adjust the tool rest to match center height. |

| 3 | Engage the tool slowly into the workpiece. |

| 4 | Maintain a steady feed rate. |

Precision is key! So, keep practicing for smooth and clean cuts. If at first, you don’t succeed, you’re probably just putting too much pressure on the tool. Just like a dog chasing its tail, sometimes it helps to step back and try again!

Maintenance and Care of Parting Tools

Best practices for cleaning and sharpening tools. How to extend the lifespan of your parting tool.Keeping your parting tools in good shape is key to great cuts and happy metalworking sessions. First, always clean your tools after use. A quick wipe-down removes chips and grime, giving your tools a longer life. For sharpening, use a fine stone; it’s like a spa day for your tools! To keep them healthy, store them in a dry place to avoid rust. Remember, a happy parting tool makes the job easier – no one likes a grumpy one!

| Best Practices | Benefits |

|---|---|

| Clean tools after each use | Prevents rust and buildup |

| Sharpen regularly | Improves cutting efficiency |

| Store in a dry place | Extends lifespan |

Common Challenges and Solutions in Parting

Identifying issues (e.g., tool chatter, overheating). Troubleshooting tips and solutions.Parting can be tricky, but with the right tips, you can avoid common headaches. One challenge is tool chatter, which makes your cuts uneven. If you notice this, check your tool speed and feed rate. Another issue is overheating, which can ruin your tools. To fix this, use cutting oil to keep things cool. Below is a handy table to help you troubleshoot these problems:

| Issue | Solution |

|---|---|

| Tool Chatter | Adjust speed and feed rate |

| Overheating | Apply cutting oil |

With these tips, you’ll be parting like a pro in no time. Just remember, if your lathe starts singing a sad tune, it’s time to give it a little TLC!

Comparative Analysis: Parting Tools vs. Other Cutting Tools

Advantages of using a parting tool over other cutting tools. Situations where alternative tools may be more effective.Parting tools are like the superheroes of cutting tools! They’re perfect for slicing off a piece of metal quickly. One big perk is their ability to create clean edges. Other tools, like saws, might leave a rough finish that looks like a dog chewed on it. However, a parting tool excels in narrow spaces, while a bandsaw could shine in larger cuts. Sometimes, less is more, but this is tool talk—so, it’s all about finding the right fit for your project!

| Tool Type | Advantage | Ideal Situation |

|---|---|---|

| Parting Tool | Clean edges | Narrow cuts |

| Bandsaw | Efficient for large sections | Big material pieces |

Innovations in Parting Tool Technology

Recent advancements in material and design. Future trends in lathe cutting tools.Technology is changing how we make lathe parting tools. New materials are stronger and last longer. Designers are creating tools that cut better and are easier to use. In the future, we might see:

- More tools using advanced materials, like carbide composites.

- Smart tools that track their usage and performance.

- Eco-friendly designs to reduce waste.

These innovations will help makers work faster and smarter.

What are the latest advancements in parting tool technology?

Recent advancements include better materials and innovative designs for improved efficiency and durability.

User Reviews and Experiences

Summary of feedback from metalworking professionals. Insights from hobbyists and DIY enthusiasts.Many metalworking pros share their thoughts on lathe parting tools. Reviews often highlight their sharpness and ease of use. Hobbyists praise these tools for making their projects smoother and quicker. They feel confident when using them.

- Pros: Great precision and powerful cutting.

- Cons: Some tools may chip with hard metals.

- Best for: Both beginners and seasoned makers.

Overall, users agree that investing in quality lathe parting tools can lead to better results in any metalworking task.

What do users say about lathe parting tools?

Users often express satisfaction due to their performance and reliability in projects.

Conclusion

In summary, lathe parting tools are essential for cutting and shaping metal. They help you create precise edges and grooves. Remember to choose the right tool for your project. Practice using these tools to improve your skills. We encourage you to explore more about metal lathe cutting tools for better understanding. Keep experimenting, and you’ll become a master in no time!FAQs

What Is The Purpose Of A Parting Tool In Metal Lathe Operations, And How Does It Differ From Other Cutting Tools?A parting tool is used in a metal lathe to cut pieces off a metal rod. It helps you separate one item from another, like cutting a cake. Unlike other tools that shape metal, the parting tool slices through it. It’s usually thinner and sharper than regular cutting tools. This lets it make a clean cut without damaging the rest of the metal.

What Materials Are Commonly Used For Manufacturing Lathe Parting Tools, And How Do These Materials Affect Tool Performance?Lathe parting tools are often made from high-speed steel (HSS) or carbide. HSS is strong and can handle heat well, making it last longer. Carbide is even harder and stays sharp for a long time but can break more easily. The choice of material affects how well the tool cuts and how long it lasts.

How Do You Properly Set Up And Adjust A Parting Tool For Optimal Results When Cutting Metal On A Lathe?To set up a parting tool on a lathe, first, make sure the tool is tight in the holder. Position the tool so the cutting edge is level with the center of the metal. Next, adjust the tool so it sticks out just a little bit from the holder. When you start cutting, go slowly and check the cut often to make sure it’s even. If needed, you can adjust the tool again for better results.

What Are The Common Techniques For Using A Parting Tool Efficiently And Safely In Lathe Operations?To use a parting tool safely on a lathe, always wear safety glasses. Make sure the tool is sharp and in good shape. Keep your hands clear of the cutting area and stay focused. Move the tool slowly and smoothly, taking small cuts. Finally, always check that the lathe is turned off before changing tools.

What Factors Should Be Considered When Selecting A Parting Tool Size And Shape For Specific Metalworking Projects?When choosing a parting tool, first think about the size of the metal you’re cutting. A bigger piece may need a wider tool. Next, consider how deep you need to cut. A longer tool can reach farther. Finally, check the shape; some shapes work better for tight spots while others are best for straight cuts.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Is The Purpose Of A Parting Tool In Metal Lathe Operations, And How Does It Differ From Other Cutting Tools? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A parting tool is used in a metal lathe to cut pieces off a metal rod. It helps you separate one item from another, like cutting a cake. Unlike other tools that shape metal, the parting tool slices through it. It’s usually thinner and sharper than regular cutting tools. This lets it make a clean cut without damaging the rest of the metal.”}},{“@type”: “Question”,”name”: “What Materials Are Commonly Used For Manufacturing Lathe Parting Tools, And How Do These Materials Affect Tool Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe parting tools are often made from high-speed steel (HSS) or carbide. HSS is strong and can handle heat well, making it last longer. Carbide is even harder and stays sharp for a long time but can break more easily. The choice of material affects how well the tool cuts and how long it lasts.”}},{“@type”: “Question”,”name”: “How Do You Properly Set Up And Adjust A Parting Tool For Optimal Results When Cutting Metal On A Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a parting tool on a lathe, first, make sure the tool is tight in the holder. Position the tool so the cutting edge is level with the center of the metal. Next, adjust the tool so it sticks out just a little bit from the holder. When you start cutting, go slowly and check the cut often to make sure it’s even. If needed, you can adjust the tool again for better results.”}},{“@type”: “Question”,”name”: “What Are The Common Techniques For Using A Parting Tool Efficiently And Safely In Lathe Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To use a parting tool safely on a lathe, always wear safety glasses. Make sure the tool is sharp and in good shape. Keep your hands clear of the cutting area and stay focused. Move the tool slowly and smoothly, taking small cuts. Finally, always check that the lathe is turned off before changing tools.”}},{“@type”: “Question”,”name”: “What Factors Should Be Considered When Selecting A Parting Tool Size And Shape For Specific Metalworking Projects? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a parting tool, first think about the size of the metal you’re cutting. A bigger piece may need a wider tool. Next, consider how deep you need to cut. A longer tool can reach farther. Finally, check the shape; some shapes work better for tight spots while others are best for straight cuts.”}}]}