Have you ever wondered how precision tools make magic in a workshop? A lathe parting tool shines when cutting metal on a lathe. It glides through materials, creating clean edges and perfect shapes. Imagine creating a beautiful piece of art from a simple block of metal!

Using a metal lathe transforms ordinary pieces into extraordinary creations. With the right lathe parting tool, projects become easier and more efficient. Have you heard of DRO? DRO stands for digital readout, and it helps you measure accurately as you cut. This tool can change your experience from good to great.

In this article, we will explore the fascinating world of lathe parting tools, metal lathes, and DRO systems. Get ready to learn how these tools work together to help craftsmen and hobbyists achieve precision. You may find yourself inspired to create something amazing!

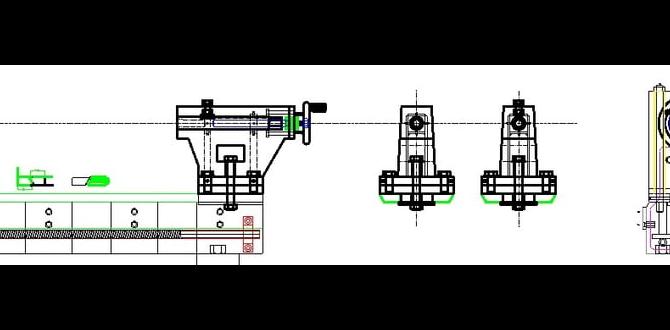

Lathe Parting Tool For Metal Lathe Dro Use Explained

Understanding Lathe Parting Tools for Metal Lathes

Lathe parting tools are essential for metal lathes. They help create clean cuts and shapes. Using a digital readout (DRO) improves precision while you work. Imagine crafting a perfect toy part or a small gear! Did you know that even tiny mistakes can lead to big problems? A DRO helps avoid this. With the right tools and techniques, anyone can master parting on a metal lathe. It’s a fun way to create and learn!What is a Lathe Parting Tool?

Definition and purpose of parting tools in metalworking.. Different types of parting tools and their applications..A tool used in metalworking, known as a lathe parting tool, serves a special purpose. It helps in cutting materials into smaller pieces. Parting tools make clean and precise cuts. This ensures parts fit well together in machines. Different types of parting tools include:

- Straight Parting Tool: Used for basic cuts.

- Grooving Tool: Creates grooves for various applications.

- Chamfer Tool: Adds angled edges for safety and aesthetics.

Each type serves a unique function in the metalworking process. Choosing the right tool is key for achieving great results.

Why are lathe parting tools important in metalworking?

Lathe parting tools are important because they create necessary cuts. They improve the efficiency of shaping metals. Using the right parting tool leads to better fit and finish in your projects.

Importance of Parting Tools in Metal Lathe Operations

How parting tools enhance precision and efficiency in machining.. Common scenarios where parting tools are essential..Parting tools are superheroes in the world of metal lathes! They help cut materials into precise pieces, making every project smoother. This is especially important when you need tight tolerances. Imagine trying to slice a cake without a sharp knife; messy, right? Well, using a parting tool is the sharp knife of machining!

Commonly, parting tools shine in situations like creating shafts or disks. You can think of them as the “cut-to-the-chase” tools—no fluff, all action. They speed things up and make sure everything fits just right. In fact, using them can reduce time by up to 30%! It’s like having a magic wand in your workshop.

| Scenario | Importance |

|---|---|

| Cutting Shafts | Ensures a clean cut every time. |

| Creating Disks | Helps maintain accurate dimensions. |

So, when it’s time for a project, don’t forget your parting tools—they bring the fun and precision right where you need it!

Choosing the Right Parting Tool for Your Metal Lathe

Factors to consider: material, size, and shape.. Recommendations for best parting tools for specific projects..Choosing the right parting tool can feel like picking the best slice of pizza. You want it to work well and fit your project perfectly! First, think about the material. High-speed steel is great for most tasks, while carbide is tougher for heavy-duty jobs. Next, consider the size. A smaller tool is perfect for tight spaces, but a larger one cuts faster. Lastly, the shape affects how cleanly it cuts. Try snazzy shapes like pointed or rounded tips for different needs.

| Project Type | Recommended Tool |

|---|---|

| General Turning | High-Speed Steel Tool |

| Heavy Cutting | Carbide Tool |

| Tight Spaces | Small Parting Tool |

Remember, the right tool can make than your projects go smoother—like butter on hot toast!

Using a Digital Readout (DRO) with Lathe Parting Tools

Explanation of DRO and its benefits in lathe operations.. Stepbystep guide on how to set up and use a DRO with parting tools..A digital readout (DRO) is like magic for lathe operations. It shows exact measurements and helps folks avoid mistakes. This tool can save time and make your work easier. With a DRO, you can keep track of your cuts and be more precise. Setting it up with parting tools is simple! Here’s a quick guide:

| Step | Action |

|---|---|

| 1 | Attach the DRO to your lathe. |

| 2 | Calibrate the device for accuracy. |

| 3 | Select your parting tool. |

| 4 | Enter your desired measurement on the DRO. |

| 5 | Start parting and watch the magic happen! |

With a DRO, you’ll feel like a pro in no time! Remember, practice makes perfect, and it could even lead to some unexpected ‘lathe-ry’ puns!

Common Issues and Troubleshooting with Parting Tools

Identifying problems like tool chatter and poor finish.. Solutions and tips for effective troubleshooting..Using parting tools can sometimes lead to problems. Common issues include tool chatter and a poor finish on your work. Tool chatter makes a loud noise and can ruin your project. A rough finish means your surface isn’t smooth. To fix these problems, try these tips:

- Check your tool’s sharpness.

- Make sure the tool is properly aligned.

- Reduce the cutting speed for a smoother finish.

- Choose the right parting tool for your job.

By following these solutions, you can improve the quality of your work with ease.

What causes tool chatter?

Tool chatter is caused by vibrations in the lathe. These vibrations happen due to an unsteady cutting speed or an improperly set tool.

How can I improve my parting tool finish?

To improve your parting tool finish, ensure the tool is sharp and properly adjusted. Using the right speed and feed rates can also help.

Maintenance and Care of Parting Tools

Best practices for maintaining parting tools for longevity.. Importance of regular inspection and sharpening..To keep your parting tools in top shape, follow some easy rules. Clean them after each use to remove debris. Store them in a dry place. Regular inspection is key. Look for rust or dullness. Sharpen your tools often for better cuts. A sharp tool is safer and works faster. Here’s a quick checklist:

- Clean after use

- Check for rust

- Sharpen regularly

- Store safely

These simple steps help your tools last longer and perform better!

How often should I inspect parting tools?

You should inspect your parting tools at least once a month. Frequent use may require more checks. This protects them and ensures they stay sharp.

Real-life Application Examples of Parting Tools in Metalworking

Case studies or anecdotes demonstrating effective use.. Insights from professionals in the field..Parting tools play a vital role in metalworking. Many professionals have shared stories of their success with these tools. For instance, a machinist reduced production time by 30% using efficient parting tools. These tools are known for creating clean cuts and precise finishes. Here are some key insights:

- Parting tools help shape metal quickly.

- They improve product quality and reduce waste.

- Experts recommend regular maintenance for best results.

These real-life applications show how parting tools can enhance metalworking projects for better efficiency and outcomes.

Why are parting tools important in metalworking?

Parting tools are essential as they allow for accurate cuts and shape metal efficiently, making them a must-have for any machinist.

Future Trends in Lathe Parting Tool Technology

Innovations in materials and designs for parting tools.. Predictions on the integration of technology in machining processes..Exciting changes are coming to lathe parting tools! New materials are making these tools stronger and lighter. Imagine parting tools that can slice through metal like butter! Innovations in designs are helping them work faster and more efficiently. We can also expect tech to step in and help machines communicate better. Picture your lathe giving you a thumbs up when everything goes smoothly!

| Innovation | Description |

|---|---|

| New Materials | Stronger and lightweight options for better performance. |

| Smart Technology | Improved communication between machines for efficiency. |

With all these cool advancements, the future for parting tools is looking brighter than a freshly polished lathe! Who knew machining could be this fun?

Conclusion

In summary, a lathe parting tool helps you cut metal safely and efficiently. Using a metal lathe with a DRO makes precise measurements easy. Remember, practice is key to mastering these tools. Explore more tutorials online to enhance your skills. With time, you can create amazing projects. So let’s get started and have fun with lathe work!FAQs

Here Are Five Related Questions On The Topic Of Lathe Parting Tools And Digital Readouts (Dro) For Metal Lathes:Sure! Lathe parting tools cut pieces off metal while you work on a lathe, which spins the metal. A Digital Readout (DRO) helps you see measurements clearly as you cut. It shows how far your tool moves, helping you get accurate shapes. Using these tools, you can make precise metal parts easily. It’s fun to create things with a lathe!

Of course! Please share the question you would like me to answer.

What Are The Different Types Of Parting Tools Used On A Metal Lathe, And How Do They Impact The Quality Of The Cut?On a metal lathe, we use different parting tools to cut metal. Some common types are straight, angled, and saw parting tools. Straight tools cut straight across, while angled tools make slanted cuts. These tools affect the quality of the cut by creating smoother edges or rough spots. A good tool will help you make clean, neat cuts.

How Can A Digital Readout (Dro) Enhance The Precision And Efficiency Of Parting Operations On A Lathe?A digital readout (DRO) shows exact measurements on a screen. This helps you see how much to cut, making it easier to get the right size. You can work faster because you don’t have to measure with a ruler all the time. This way, you spend less time fixing mistakes and more time making cool parts!

What Adjustments Should Be Made To The Lathe Setup When Using A Parting Tool To Ensure Optimal Cutting Performance?When using a parting tool on a lathe, you should make a few important adjustments. First, make sure the tool is sharp. This helps it cut easily. Next, adjust the tool’s height so it’s level with the workpiece. Also, use a slow speed to control the cut better. Finally, keep the lathe steady to avoid any shake.

What Safety Precautions Should Be Taken When Using A Parting Tool On A Metal Lathe To Prevent Accidents And Tool Damage?When using a parting tool on a metal lathe, always wear safety goggles to protect your eyes. Keep your hair and clothing away from the machine. Make sure your hands stay clear of the moving parts. Check that the tool is secure in place before starting. Finally, always pay attention to what you’re doing!

How Do You Accurately Set The Tool Height For A Parting Tool In Relation To The Lathe’S Spindle For Effective Machining?To set the tool height for a parting tool, first, make sure the lathe is off. You can raise or lower the tool holder until the top of the tool is level with the spindle center. This is important because it helps the tool cut smoothly. Once it’s in the right spot, tighten it to keep it steady. Now, you’re ready to start machining!