Have you ever wondered how metal parts are shaped in a workshop? It’s like magic, but it’s really just great tools at work. One important tool is the lathe parting tool, which helps cut metal pieces into precise shapes.

Imagine a conveyor belt of cool gadgets being made. Each gadget starts as a block of metal. The lathe, a spinning machine, uses the parting tool to slice this block into smaller, usable parts. Pretty neat, right?

Now, let’s not forget about the gear train inside the metal lathe. This gear train makes everything run smoothly. It helps control the speed and movement of the lathe, making sure the parting tool does its job perfectly. Without it, the lathe would be much less effective.

By learning about these tools, you’ll see how they transform raw metal into amazing creations. Are you ready to dive deeper into the world of metalworking? Let’s explore!

Lathe Parting Tool: Essential For Metal Lathe Gear Train

Lathe Parting Tool Metal Lathe Gear Train

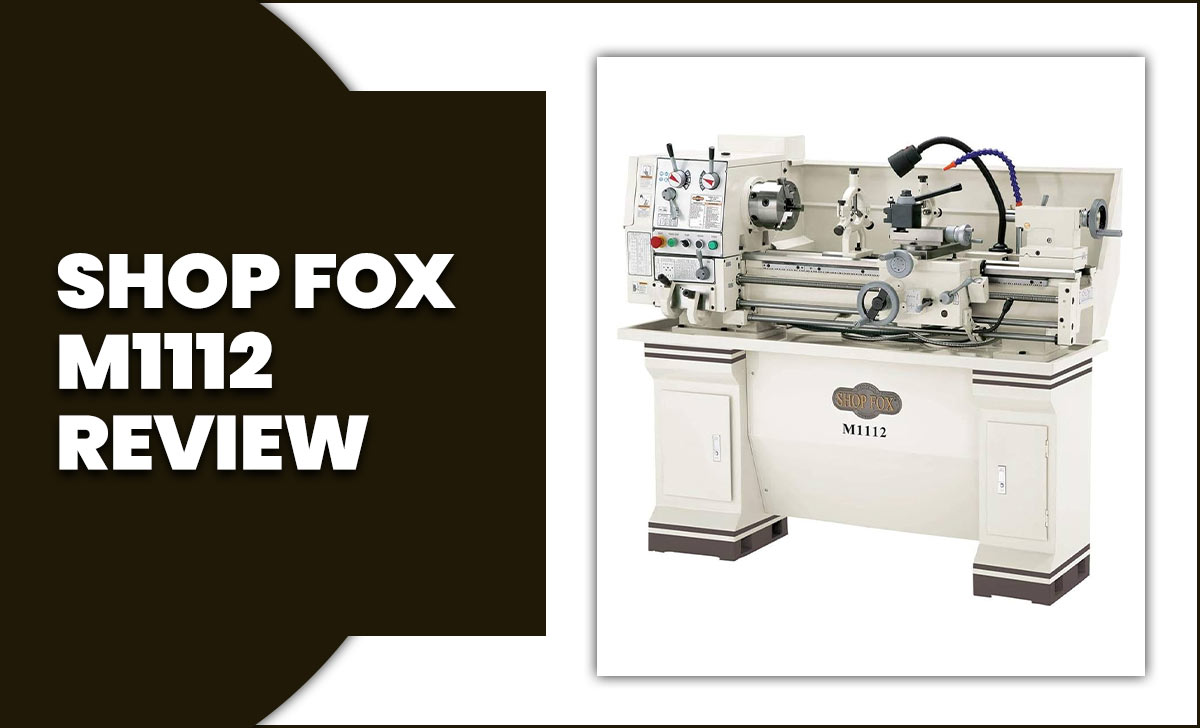

Lathe parting tools are essential for cutting metal quickly and accurately. They help machinists create precise shapes and designs. A metal lathe gear train powers the lathe, making it more efficient. Have you ever seen a lathe in action? It’s fascinating how a simple tool can shape metal into beautiful forms! Understanding how lathe parting tools and gear trains work can enhance your skills and projects. Want to learn more about creating intricate designs?Understanding Lathe Parting Tools

Definition and purpose of parting tools in metalworking. Types of parting tools and their applications.Parting tools play a key role in metalworking. They help separate pieces of metal cleanly and quickly. Imagine trying to divide a cookie with a dull knife—messy, right? That’s why we use sharp parting tools! There are several types, each for different jobs. For instance, some are used for thin cuts, while others are for thicker materials. Here’s a quick look at types of parting tools:

| Type | Application |

|---|---|

| Standard Parting Tool | Good for basic cuts in various metals. |

| Grooving Tool | Creates small grooves for fittings. |

| Heavy-Duty Parting Tool | Designed for tough materials. |

So, having the right tool makes all the difference! Fill your toolbox wisely, and you’ll be cutting through your projects like a pro.

Key Features of Quality Parting Tools

Material composition and its impact on performance. Design considerations for effective parting operations.Quality parting tools are crucial for precision work. They depend on strong materials like steel or carbide. These materials improve durability and performance, making tasks easier. A well-designed tool helps in smooth cutting. Consider these features:

- Material Composition: Steel lasts longer than other metals.

- Design: Simple shapes improve cutting efficiency.

Choosing the right tool can speed up your project and make it more enjoyable.

What are the key features of quality parting tools?

Key features include strong materials like high-speed steel and effective designs for smooth cuts. A good parting tool can make a big difference in metalworking tasks.

Selecting the Right Parting Tool for Your Lathe

Factors to consider when choosing a parting tool. Matching parting tools with different lathe types.Selecting the right parting tool for your lathe is important. Various factors can affect your choice. You need to think about:

- Material type: Make sure the tool matches the metal you’re cutting.

- Lathe compatibility: Check if the tool works well with your lathe model.

- Width and shape: Choose a size that fits your project.

Different lathes require specific tools. For example, a mini lathe needs a smaller parting tool. A larger lathe can handle wider tools. Understanding these details helps you get the best results when parting metal.

What should I look for in a parting tool?

Look for tool material, shape, and compatibility with your lathe. These factors ensure smooth cutting and great results.

Key Points:

- Right tool material.

- Tool width for your lathe.

- Shape for clean cuts.

Setting Up Your Metal Lathe for Parting Operations

Stepbystep guide to proper tool setup. Common mistakes to avoid during setup.Properly setting up your lathe is key for successful parting operations. Here’s a step-by-step guide:

- Secure your workpiece in the chuck.

- Attach the lathe parting tool in the tool holder.

- Adjust the cutting depth to 0.025 inches.

- Align the tool with the workpiece edge.

Common mistakes to avoid include:

- Using dull tools, which can damage your work.

- Incorrect tool alignment, leading to uneven cuts.

- Skipping safety checks before starting.

Following these steps will help you achieve smooth, clean cuts every time.

What should I know before setting up my metal lathe?

Check your equipment for functionality. Make sure all parts are in good condition. Read the manual carefully to understand each feature. This helps avoid mistakes and enhances safety during use.

Understanding Metal Lathe Gear Trains

Explanation of gear train components and functions. Importance of gear ratios in metal lathe operations.Gear trains are like little teams of gears working together! They help the metal lathe spin at just the right speed. Each gear connects to another and can change how fast or slow the lathe turns. This is called gear ratio. Think of it like a bicycle; if you switch gears, you go faster or slower. Good gear ratios make sure the lathe cuts neatly. It’s all about teamwork! Here’s a simple breakdown of the parts:

| Component | Function |

|---|---|

| Drive Gear | Starts the movement |

| Idler Gear | Changes direction |

| Driven Gear | Turns the lathe |

Remember, without the right gears, you might end up with a lumpy cut! Yikes!

Optimizing Gear Train Performance

Techniques for maintaining and adjusting gear trains. Troubleshooting common gear train issues.To keep your gear train running smoothly, check and tighten all connections regularly. A loose connection is like your favorite shoelace coming undone—super annoying! Use oil on moving parts for lubrication; it helps reduce wear and tear. If gears misalign, adjust them carefully so they mesh well. Always look for odd noises; they may signal trouble. Lastly, keep an eye out for wear signs, so your lathe stays happy and healthy!

| Common Issues | Solutions |

|---|---|

| Loose Gears | Tighten connections |

| Noisy Operation | Check for misalignment |

| Excess Wear | Use proper lubrication |

Advanced Techniques in Parting Operations

Tips for achieving precision and quality in parting. Innovative methods to speed up the parting process.To improve parting operations, focus on precision and quality. Here are some useful tips:

- Use sharp cutting tools for clean cuts.

- Keep your workpiece steady and well-supported.

- Adjust the speed of the lathe for better control.

Innovative methods can help speed up the process:

- Use a quick-change tool holder.

- Apply cutting fluids to reduce friction.

- Plan cuts to minimize tool changes.

These practices can lead to smoother operations and save time!

What are the best tools for parting operations?

For parting operations, use a lathe parting tool for accuracy. Look for quality tools made of durable materials. Good choices include high-speed steel or carbide-tipped options.

How can I improve my parting speed?

To improve speed, use sharp tools, adjust lathe speed, and apply cutting fluids. These methods reduce friction and allow for faster parting.

Safety Considerations when Using Parting Tools

Essential safety practices for metal lathe operations. Personal protective equipment (PPE) for lathe users.Using parting tools safely is very important. Always wear the right safety gear. This includes goggles to protect your eyes and gloves to keep your hands safe. Here are some essential safety practices:

- Keep your workspace clean.

- Check tools for damage.

- Don’t rush; take your time.

- Follow machine instructions carefully.

Remember, safety first! Following these simple tips can help prevent accidents and keep you safe while using metal lathes.

What personal protective equipment should I use?

Always use proper safety gear for lathe work. Essential equipment includes safety goggles, gloves, and ear protection. This gear helps protect you from flying debris and loud noises.

Conclusion

In conclusion, a lathe parting tool is essential for cutting metal on a lathe. The gear train helps control the lathe’s movement. Understanding how these parts work improves your skills. You can create precise designs and shapes with practice. We encourage you to explore more about lathes or try using one yourself. Start experimenting today!FAQs

What Is The Primary Function Of A Parting Tool In A Metal Lathe, And How Does It Differ From Other Cutting Tools?A parting tool in a metal lathe helps cut pieces of metal apart. You use it to create a gap or separate one part from another. This tool is different from others because it cuts straight down instead of twisting or shaping. Other cutting tools can shape or smooth metal, while the parting tool is just for cutting.

How Does The Gear Train Function In A Metal Lathe, And What Role Does It Play In Controlling Spindle Speed?In a metal lathe, the gear train is a set of gears that works together. It helps change how fast the spindle turns. The spindle is the part that holds the tool to shape metal. By switching gears, we can make the spindle spin faster or slower for different jobs. This control lets us make precise cuts on the metal.

What Materials Are Commonly Used To Make Lathe Parting Tools, And What Properties Make Them Suitable For Metal Cutting?Lathe parting tools are often made from high-speed steel or carbide. High-speed steel is tough and can handle heat well. Carbide is very hard and stays sharp for a long time. Both materials help us cut metal easily and accurately. They are great for making clean cuts and last a long time.

How Can Improper Use Of A Parting Tool Affect The Performance Of A Metal Lathe And The Quality Of The Workpiece?If you use a parting tool wrong, it can cause problems. The metal lathe might shake or slow down. This makes your cuts uneven or rough. As a result, the finished piece won’t look nice or work well. Always use the tool properly for the best results!

What Adjustments Can Be Made To The Gear Train Of A Metal Lathe To Optimize The Cutting Speed When Using A Parting Tool?To optimize cutting speed on a metal lathe with a parting tool, you can change the gear ratio. This makes the lathe spin faster. You can also adjust the belts to give you more speed. Lastly, make sure the tool is at the right angle to cut smoothly. These changes help you cut better and quicker!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Is The Primary Function Of A Parting Tool In A Metal Lathe, And How Does It Differ From Other Cutting Tools? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A parting tool in a metal lathe helps cut pieces of metal apart. You use it to create a gap or separate one part from another. This tool is different from others because it cuts straight down instead of twisting or shaping. Other cutting tools can shape or smooth metal, while the parting tool is just for cutting.”}},{“@type”: “Question”,”name”: “How Does The Gear Train Function In A Metal Lathe, And What Role Does It Play In Controlling Spindle Speed? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In a metal lathe, the gear train is a set of gears that works together. It helps change how fast the spindle turns. The spindle is the part that holds the tool to shape metal. By switching gears, we can make the spindle spin faster or slower for different jobs. This control lets us make precise cuts on the metal.”}},{“@type”: “Question”,”name”: “What Materials Are Commonly Used To Make Lathe Parting Tools, And What Properties Make Them Suitable For Metal Cutting? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe parting tools are often made from high-speed steel or carbide. High-speed steel is tough and can handle heat well. Carbide is very hard and stays sharp for a long time. Both materials help us cut metal easily and accurately. They are great for making clean cuts and last a long time.”}},{“@type”: “Question”,”name”: “How Can Improper Use Of A Parting Tool Affect The Performance Of A Metal Lathe And The Quality Of The Workpiece? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If you use a parting tool wrong, it can cause problems. The metal lathe might shake or slow down. This makes your cuts uneven or rough. As a result, the finished piece won’t look nice or work well. Always use the tool properly for the best results!”}},{“@type”: “Question”,”name”: “What Adjustments Can Be Made To The Gear Train Of A Metal Lathe To Optimize The Cutting Speed When Using A Parting Tool? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To optimize cutting speed on a metal lathe with a parting tool, you can change the gear ratio. This makes the lathe spin faster. You can also adjust the belts to give you more speed. Lastly, make sure the tool is at the right angle to cut smoothly. These changes help you cut better and quicker!”}}]}