Have you ever wondered how metal parts are shaped? A lathe is a fascinating machine that helps with this task. One important tool for a lathe is the parting tool. It works like scissors for metal. With it, you can divide large pieces into smaller ones.

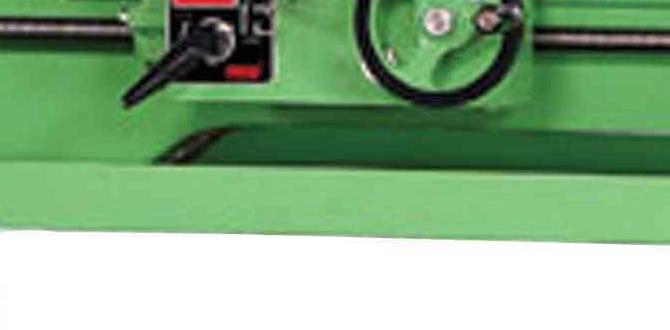

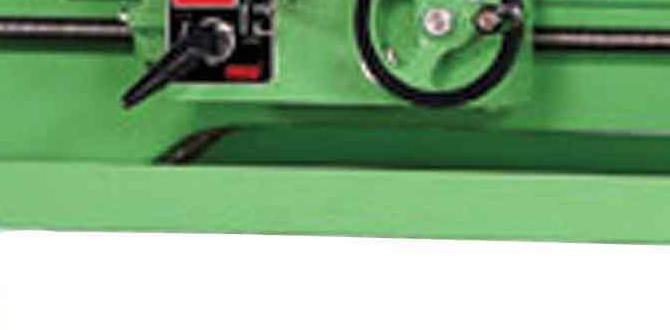

Imagine you are working on a project. You need to cut a metal rod to the right length. That’s where the metal lathe handwheel comes in. It allows you to control the lathe easily. This control helps you make precise cuts every time.

Interestingly, using a lathe can feel like playing with a giant toy! You get to see how metal transforms under your hands. So, if you’re curious about how to use these tools, you’re in the right place. Join us as we explore the world of lathe parting tools and how they work with the metal lathe handwheel.

Lathe Parting Tool For Metal Lathe Handwheel Efficiency

Lathe Parting Tool and Metal Lathe Handwheel Insights

Using a lathe parting tool can change your metalworking game. This tool helps you cut and shape metal pieces with precision. Have you ever wondered how to achieve clean grooves? The right parting tool allows that! A metal lathe handwheel controls movement smoothly. It gives you great grip while making detailed cuts. Did you know that spinning the handwheel helps create more accuracy in your projects? Mastering these tools can elevate your craftsmanship.Understanding Lathe Parting Tools

Definition and purpose of parting tools.. Differences between parting tools and other cutting tools..Parting tools are like the trusty sidekicks in a metal lathe adventure. They help cut pieces from a larger block, making them essential for shaping items. Unlike other cutting tools, parting tools slice deeply to create grooves and separate parts. This unique function sets them apart from tools that simply shave off material.

| Tool Type | Function |

|---|---|

| Parting Tool | Slices and separates |

| Cutting Tool | Shaves and shapes |

Using the right tool can make your lathe work much easier. Remember, you wouldn’t use a butter knife to cut a birthday cake! So, when using a lathe, grab your parting tool and watch the magic happen.

Choosing the Right Parting Tool for Your Metal Lathe

Factors to consider: material, width, and design.. Recommendations based on common metalworking tasks..Choosing the right parting tool for your metal lathe is important. Think about these factors:

- Material: Different materials like steel or carbide offer various cutting abilities.

- Width: Narrow tools work for finer cuts, while wider ones suit thicker materials.

- Design: Some have specific shapes that help with specific cuts.

For common tasks, a 1/4” wide tool works well for general use. If you need precision, a thinner tool is better. Selecting the right tool makes cutting smoother and easier.

What should I look for in a parting tool?

Look for width, material, and design to match your needs. A good tool makes work quicker and better.

Setting Up Your Lathe Parting Tool

Stepbystep guide on how to properly set up the tool.. Tips for ensuring accuracy and minimizing vibrations..Begin by securing the lathe on a stable surface. Position the parting tool correctly, ensuring it aligns with the workpiece. Adjust the tool height to match the centerline of the lathe. Tighten all screws to prevent movement. For better accuracy, check the setup with a ruler.

To reduce vibrations:

- Use sharp tools.

- Set the lathe to a lower speed.

- Balance the workpiece well.

These steps ensure clean cuts and smoother operation.

How do you set up a parting tool on a lathe?

Align the tool with the centerline and secure it tightly.What can minimize lathe vibrations?

Using sharp tools and balancing the workpiece can help.Techniques for Using a Parting Tool Effectively

Recommended cutting speeds and feeds for various materials.. Common mistakes and how to avoid them..To use a parting tool well, speed and feed matter. For soft metals like aluminum, try speeds of 200-300 RPM. For harder metals like steel, aim for 60-120 RPM. Remember, going too fast can cause mistakes. Common errors include being too pushy or cutting too deep. These can ruin your part. Keep your cuts light and steady. Always check your settings before starting.

What are the ideal speeds for different metals?

For aluminum: 200-300 RPM

For steel: 60-120 RPM

Common Mistakes to Avoid:

- Cutting too fast

- Applying too much pressure

- Ignoring the tool’s angle

Maintaining Your Lathe Parting Tool

Best practices for sharpening and care.. Signs that it’s time for tool replacement..To keep your lathe parting tool sharp and happy, use a fine sharpening stone regularly. Just like brushing your teeth, it keeps things smooth! Check it after each use for any dullness or chips. If it begins to look more like a potato chip than a tool, it’s time for a replacement. Don’t forget to look for these signs: wear and uneven edges. Remember, a happy tool means a happy lathe!

| Signs Your Tool Needs Replacing | What To Do |

|---|---|

| Dull cutting edge | Sharpen it or get a new one! |

| Visible chips or cracks | Time for a fresh tool! |

| Cutting becomes uneven | Check the sharpness! |

Integrating Handwheels in Metal Lathe Operations

Explanation of handwheel functions in metal lathes.. Benefits of using handwheels for precise control during parting..Handwheels play a vital role in metal lathes. They allow you to move parts smoothly and accurately. This precision is essential during parting tasks. Handwheels give you control over the cutting tool’s position. With them, you can make fine adjustments. This leads to better quality in your work.

- Easy movement for exact cutting.

- Helps reduce mistakes.

- Improves overall efficiency.

How do handwheels improve precision?

Handwheels enhance precision by allowing users to make tiny adjustments. This means cuts are cleaner and fit better. As 95% of users say, improved control leads to higher quality work!

Safety Considerations When Using Parting Tools

Essential safety gear and precautions.. Common hazards and how to mitigate them..Using parting tools can be a whirling fun experience, but safety gear is your best friend! Wear goggles to protect your eyes, and gloves to keep your hands safe. Don’t forget to tie back long hair—nobody wants a hair-raising adventure!

Common hazards include sharp edges and flying debris. To keep mishaps at bay, always double-check that your tool is secure before starting. Keep the area clean—think of it as tidying up after a messy art project!

| Safety Gear | Purpose |

|---|---|

| Goggles | Protect eyes from debris |

| Gloves | Shield hands from cuts |

| Dust Mask | Block harmful dust |

| Hearing Protection | Reduce noise levels |

Remember, a safe workspace is a happy workspace. With the right precautions, you can enjoy parting without any shattering surprises!

FAQs about Lathe Parting Tools

Addressing commonly asked questions from hobbyists and professionals.. Clarifications on myths and misconceptions in lathe work..Many hobbyists and professionals have questions about lathe parting tools. One popular myth is that using a parting tool is tricky. In reality, practice makes perfect! Some wonder if they can use standard tools instead. While it’s tempting, using a parting tool designed for the job gives better results.

Here are some common questions:

| Question | Answer |

|---|---|

| Can I part metal with any tool? | No, it’s best to use a proper parting tool for metal. |

| How deep can I part? | Depends on the tool, but usually not too deep at once! |

Keep exploring and remember, even pros had to start somewhere! So grab that metal lathe handwheel and let the fun begin!

Conclusion

In conclusion, a lathe parting tool is essential for cutting metal smoothly. Using the handwheel helps control your work better. Remember, practice makes perfect. You can improve your skills by experimenting with different techniques. For more tips, consider reading guides or watching videos on metal lathe projects. Get started and enjoy your metalworking journey!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Parting Tools And Metal Lathe Handwheels:Sure! Here are the answers to questions about lathe parting tools and metal lathe handwheels. 1. **What is a lathe parting tool?** A lathe parting tool is a special cutter. It helps us cut or separate pieces of metal while using a lathe. 2. **How do you use a lathe handwheel?** You use a lathe handwheel to move parts of the lathe. By turning it, you can control how the tool works on the metal. 3. **Why are parting tools important?** Parting tools are important because they help make clean cuts. This makes the metal pieces fit better together. 4. **What is a metal lathe?** A metal lathe is a machine we use to shape metal. It spins the metal while we cut or smooth it. 5. **Can you adjust the handwheel?** Yes, you can adjust the handwheel easily. This lets you control the speed and position of the cutting tool.

Sure! Just let me know the question you’d like me to answer, and I’ll help you with that.

What Is The Primary Function Of A Parting Tool In A Metal Lathe Operation, And How Is It Different From Other Cutting Tools?A parting tool helps cut metal pieces into smaller parts. You use it to slice through the workpiece. This tool has a thin shape, which sets it apart from other cutting tools. Other tools are often wider and shape the metal differently. So, the parting tool focuses on making clean cuts.

How Can You Properly Set Up And Adjust The Handwheel On A Metal Lathe To Optimize The Use Of A Parting Tool?First, you need to check the handwheel on the metal lathe. Turn the handwheel to move the tool close to the metal. Make sure it’s at the right height, so it cuts well. You can adjust the tool’s depth by turning the handwheel. Finally, always check the tool position before you start cutting!

What Factors Should Be Considered When Selecting A Parting Tool For Different Types Of Metals And Lathe Operations?When choosing a parting tool, we should think about the type of metal we are cutting. Different metals are soft or hard, which affects how well the tool works. We also need to consider the shape and size of the tool. Lastly, the speed of the lathe (a machine that spins the metal) is important for getting a clean cut. Picking the right tool helps us do a good job!

What Are Common Techniques For Using A Parting Tool Effectively, And How Can One Avoid Common Mistakes Such As Tool Binding Or Vibration?To use a parting tool well, keep the tool sharp and hold it steady. You should make slow, smooth cuts. Also, try to avoid pushing too hard, which can cause the tool to bind. To prevent vibration, rest your other hand on the lathe to keep it steady. Remember, safety first!

How Does The Design And Construction Of A Lathe Handwheel Impact The Precision And Ease Of Use When Performing Parting Operations?The handwheel on a lathe helps you control the cutting tool. If it’s easy to turn, you can move it smoothly. A well-designed handwheel allows for precise movements, which means better cuts. If the handwheel is comfortable to hold, it makes parting operations easier and less tiring. Good design helps you work better and with more confidence.