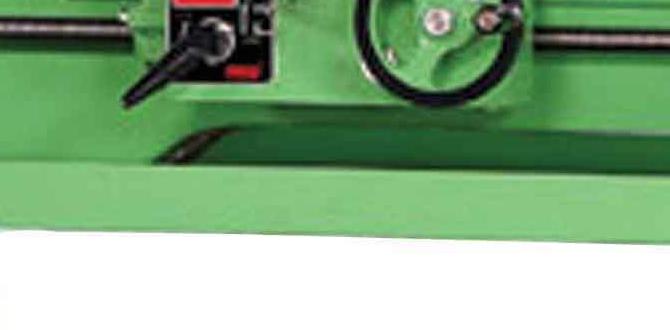

Have you ever wondered how a lathe works? It’s a fascinating machine that shapes metal. One of the essential tools in a lathe is the parting tool. This tool helps cut metal pieces into smaller parts. But what happens when your metal lathe needs maintenance?

Many people don’t realize how important it is to take care of these machines. Proper maintenance can keep your lathe running smoothly for years. Imagine trying to create a perfect part but facing problems because of a dull tool or a dirty machine. Frustrating, right?

Surprisingly, a little care goes a long way. Simple tasks like cleaning and checking parts can make a big difference. Joining us in exploring metal lathe maintenance will help you learn how to use a lathe parting tool effectively and ensure your machine is always in top shape.

Lathe Parting Tool: Essential Metal Lathe Maintenance Tips

Lathe Parting Tool Metal Lathe Maintenance

Maintaining your lathe parting tool is essential for smooth operation. A clean tool provides better performance and extends its life. Regular checks for wear and tear can prevent accidents. Did you know that dull blades can cause more harm than good? Keeping them sharp ensures clean cuts and reduces effort. Simple cleaning and lubrication can make a big difference. Invest time in your tools; they deserve it! Happy turning!Understanding Lathe Parting Tools

Definition and function of parting tools in metal lathes. Common types of parting tools and their applications.Parting tools are special tools used on metal lathes. They help cut materials into smaller pieces. These tools work like scissors for metal. Common types include:

- **Straight Parting Tool**: Used for simple cuts.

- **Notched Parting Tool**: Helps create grooves.

- **T-Shaped Parting Tool**: Good for larger cuts and deeper grooves.

Each tool has its own purpose. Choosing the right one is key for successful metalworking.

What are common types of lathe parting tools?

Common types include straight, notched, and T-shaped parting tools. Each serves different functions in metal cutting.

Importance of Proper Maintenance

Impact of maintenance on tool performance and longevity. Cost implications of neglecting maintenance.Keeping tools in shape is like giving your pet a bath—it’s essential! Proper maintenance can lead to better tool performance. A well-maintained lathe parting tool smooths cuts like butter. On the flip side, neglect can be costly. You might face repairs or replacements that can break the bank. A little TLC goes a long way, saving you time and money. Remember, “A happy tool is a sharp tool!”

| Maintenance Aspect | Impact on Performance | Cost Implications |

|---|---|---|

| Regular Cleaning | Prevents rust and improves cuts | Reduces need for replacements |

| Lubrication | Enhances movement and accuracy | Minimizes wear and tear costs |

| Inspection | Detects issues early | Saves on major repairs |

Daily Maintenance Routines for Lathe Parting Tools

Steps for cleaning and lubricating parting tools. Checking for wear and damage.To keep your lathe parting tools in top shape, follow some simple steps. First, give them a good cleaning. Wipe off any debris with a cloth. Next, add a drop of oil for lubrication. This keeps the tools smooth and happy. Regularly check for wear and damage. Look for cracks or chips. A worn out tool isn’t fun to use! Remember, an ounce of prevention is worth a pound of cure—so don’t skip this step!

| Maintenance Steps | Description |

|---|---|

| Cleaning | Wipe off debris with a soft cloth. |

| Lubrication | Apply a drop of oil to keep things smooth. |

| Check for Wear | Inspect for cracks or chips. |

Periodic Maintenance Checks

Schedule and frequency for indepth inspections. Evaluating tool sharpness and replacing dull blades.Regular check-ups are important to keep your lathe working well. Plan inspections every month. During these checks, look closely at all parts. Make sure to check the sharpness of your tools. Sharp tools are safer and do a better job. If any blades are dull, replace them with new ones. Replace dull blades immediately to avoid accidents or poor cuts.

How often should maintenance be done?

Monthly checks are ideal for maintenance. This ensures tools work properly and stay safe.

- Inspect all lathe parts.

- Evaluate tool sharpness.

- Replace any dull blades right away.

Common Issues and Troubleshooting

Identifying signs of tool wear and malfunction. Solutions for common maintenance problems.To keep your lathe tools in top shape, watch for signs of wear. If your cuts are rough or uneven, it’s time to act. You might see chips or a shiny blade. These are signs your tool needs help. Regular maintenance can fix common issues:

- Check for rust and clean it.

- Sharpen blades regularly.

- Adjust tool height for better performance.

- Keep the lathe well-lubricated.

Doing these tasks will extend your tool’s life and ensure smooth operation.

What are the signs of tool wear?

Signs include rough cuts, shiny blades, and visible chips.Best Practices for Longevity of Parting Tools

Proper usage techniques to minimize wear. Importance of calibration and settings in tool performance.Using your parting tool correctly can help it last longer. Make sure to hold it firmly but gently. Too much pressure can cause wear. Also, check the tool’s settings. Finding the right speed and depth is crucial. This will improve your cuts and keep the tool sharp. Here are some tips:

- Use it at the right speed.

- Don’t push too hard.

- Regularly check the tool for wear.

- Adjust your settings as needed.

How to keep parting tools effective?

Proper maintenance and correct usage guarantee efficiency and stamina. Calibration ensures smooth performance. Always remember to check often for signs of wear and adjust as needed.

Upgrading Your Parting Tool for Enhanced Performance

When to consider upgrading your tool. Features to look for in modern parting tools.Thinking about a new parting tool? A good time to upgrade is when your current tool feels like it’s stuck in the Stone Age. Look for features like better materials and precision design. Modern tools often have coatings to reduce wear and tear, making them last longer. Remember, a sharper tool can save frustrating hours at the lathe!

| Feature | Benefit |

|---|---|

| Material Quality | Increased durability and performance |

| Coating Technology | Less friction and longer life |

| Precision Design | Better accuracy in cutting |

Upgrading can turn your time at the lathe from “meh” to “wow!” So don’t wait. Your projects deserve the best tools!

Resources and Tools for Maintenance

Recommended products for tool care. Where to find reliable maintenance guides and tutorials.Keeping your tools happy is key! For maintaining your lathe, start with proper products. Look for oil and cleaning solutions that keep everything running smoothly. Check out your local hardware store or online markets for trusted brands.

Need help? Websites like YouTube and specialized forums are treasure troves of guides. They have videos showing neat ways to care for your tools. You can almost say that these sites are like your tool’s best friends!

| Recommended Products | Where to Find Guides |

|---|---|

| Quality Cutting Oil | YouTube Tutorials |

| Rust Remover | Tool Maintenance Blogs |

Remember, a well-maintained lathe is a happy lathe. Happy tools make for happy projects—no grumpy machines allowed!

Conclusion

In conclusion, taking care of your lathe parting tool is essential for smooth metal lathe operations. Regular maintenance keeps your tools sharp and effective. You can check for wear, clean them often, and store them properly. Explore more resources to learn about lathe care. By doing this, you ensure your projects are easier and more enjoyable. Happy machining!FAQs

What Are The Best Practices For Sharpening A Lathe Parting Tool To Ensure Clean And Accurate Cuts In Metalworking?To sharpen a lathe parting tool, first, use a sharpening stone or grinder. Hold the tool at a steady angle while sharpening. Make sure to create a thin, sharp edge for clean cuts. Check your work often to see if it’s getting sharper. Finally, be careful and keep your fingers away from the blade!

How Often Should Lathe Parting Tools Be Inspected And Maintained To Prevent Wear And Damage During Use?You should check your lathe parting tools before each use. Look for any damage or dull edges. If they are worn out, sharpen or replace them. Regular maintenance helps keep them safe and working well. Taking care of your tools makes your work easier!

What Types Of Lubricants Or Coolant Should Be Used When Operating A Metal Lathe With A Parting Tool To Extend Tool Life?When using a metal lathe with a parting tool, you can use cutting oil or water-soluble coolant. Cutting oil helps keep the tool cool and reduces friction. Water-soluble coolant mixes with water for easy cleaning and cooling. Both options will help the tool last longer and work better. Always apply them while cutting to get the best results.

What Signs Indicate That A Lathe Parting Tool Needs To Be Replaced Rather Than Just Re-Sharpened?You should think about replacing a lathe parting tool if it has deep chips or cracks. If the tool is worn down to a thin edge, that’s another sign. You can also notice if it takes a lot of effort to cut. If the tool isn’t making smooth cuts anymore, it might be time for a new one. Keeping an eye on these signs helps us work better!

How Can The Setup And Alignment Of The Parting Tool In A Metal Lathe Affect The Overall Maintenance And Performance Of The Tool?When you set up the parting tool in a metal lathe, it needs to be just right. If it’s not aligned properly, the tool can wear out quickly or break. This can make your work messy and might need more repairs. By taking time to align it, you help it last longer and work better. This means you can finish your project smoothly without many issues.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Best Practices For Sharpening A Lathe Parting Tool To Ensure Clean And Accurate Cuts In Metalworking? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To sharpen a lathe parting tool, first, use a sharpening stone or grinder. Hold the tool at a steady angle while sharpening. Make sure to create a thin, sharp edge for clean cuts. Check your work often to see if it’s getting sharper. Finally, be careful and keep your fingers away from the blade!”}},{“@type”: “Question”,”name”: “How Often Should Lathe Parting Tools Be Inspected And Maintained To Prevent Wear And Damage During Use? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should check your lathe parting tools before each use. Look for any damage or dull edges. If they are worn out, sharpen or replace them. Regular maintenance helps keep them safe and working well. Taking care of your tools makes your work easier!”}},{“@type”: “Question”,”name”: “What Types Of Lubricants Or Coolant Should Be Used When Operating A Metal Lathe With A Parting Tool To Extend Tool Life? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe with a parting tool, you can use cutting oil or water-soluble coolant. Cutting oil helps keep the tool cool and reduces friction. Water-soluble coolant mixes with water for easy cleaning and cooling. Both options will help the tool last longer and work better. Always apply them while cutting to get the best results.”}},{“@type”: “Question”,”name”: “What Signs Indicate That A Lathe Parting Tool Needs To Be Replaced Rather Than Just Re-Sharpened? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should think about replacing a lathe parting tool if it has deep chips or cracks. If the tool is worn down to a thin edge, that’s another sign. You can also notice if it takes a lot of effort to cut. If the tool isn’t making smooth cuts anymore, it might be time for a new one. Keeping an eye on these signs helps us work better!”}},{“@type”: “Question”,”name”: “How Can The Setup And Alignment Of The Parting Tool In A Metal Lathe Affect The Overall Maintenance And Performance Of The Tool? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you set up the parting tool in a metal lathe, it needs to be just right. If it’s not aligned properly, the tool can wear out quickly or break. This can make your work messy and might need more repairs. By taking time to align it, you help it last longer and work better. This means you can finish your project smoothly without many issues.”}}]}