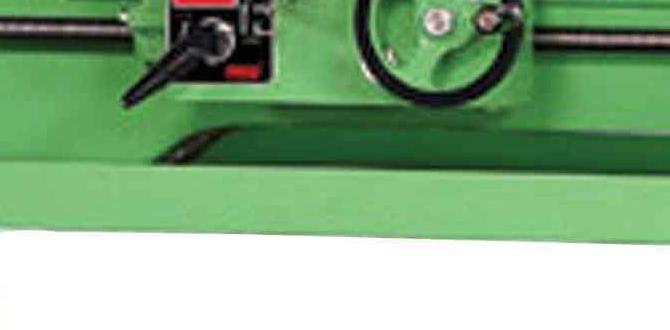

Have you ever wondered how metal parts are shaped and cut? A lathe is a fascinating machine that helps us create different objects from metal. One of the key tools for a lathe is the parting tool. This special tool allows the operator to cut metal parts into smaller pieces. It’s like cutting a cake into slices!

If you have a metal lathe motor, you can make all sorts of cool designs. The motor powers the lathe, spinning the metal so the parting tool can work its magic. It’s amazing how simple tools can create complex shapes!

Imagine you are turning a block of metal into a beautiful vase. The parting tool helps you cut it just right. Without it, making precise cuts would be very hard. Each cut you make gets you closer to your final design. Isn’t that cool?

In this article, we will explore the world of lathe parting tools and their importance. You’ll learn how they work and why every metal lathe needs one. Get ready to dive into the exciting world of metalworking!

Efficient Use Of A Lathe Parting Tool For Metal Lathe Motor

Lathe Parting Tool Metal Lathe Motor

Discover the power of a lathe parting tool in metalworking! It’s a special tool that helps cut metals cleanly and easily. Using a metal lathe motor adds strength and speed for efficient work. Have you ever wondered how metal parts are shaped so perfectly? A lathe does just that! Fun fact: most metal fabricators rely on this combination for accuracy. Learn how proper usage can elevate your crafting skills and create stunning projects.Understanding Lathe Parting Tools

Definition and purpose of lathe parting tools. Different types of parting tools and their applications.Lathe parting tools are special tools used in metalworking. They help cut materials into smaller pieces. Their main purpose is to make precise cuts on a lathe machine. There are different types of parting tools, each for various tasks:

- Standard parting tools: Used for general cutting tasks.

- Thin parting tools: Ideal for narrow cuts where precision is key.

- Grooving tools: Create grooves in the material for fittings.

These tools allow workers to shape metal accurately and efficiently.

What are lathe parting tools used for?

Lathe parting tools are used to cut metal pieces precisely. They help create smaller sections and shapes needed in projects.

Key Features to Look for in Lathe Parting Tools

Material composition and durability. Tool geometry and design for effective cutting.Finding the right lathe parting tool can feel like searching for a needle in a haystack. First off, look at the material composition. Tools made from high-speed steel or carbide last longer, which is great because no one wants a tool that throws in the towel too soon! Next, consider the tool geometry. A well-designed tool makes cutting smoother and faster. After all, who wouldn’t want to finish their project before dinner? The right combination of materials and design can make all the difference!

| Feature | Importance |

|---|---|

| Material Composition | Durability and longevity |

| Tool Geometry | Effective and smooth cutting |

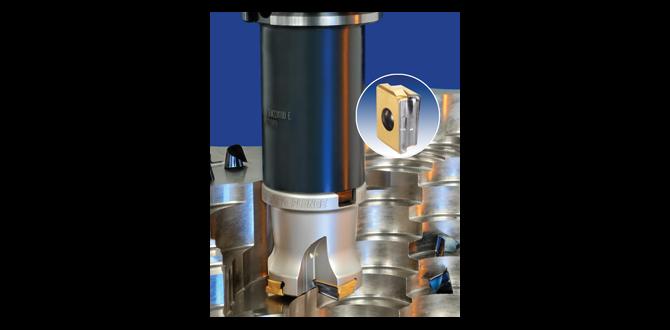

Importance of Lathe Parting Tools in Metalworking

Role in achieving precise cuts and finishes. Common applications in metal fabrication and machining.Lathe parting tools are like superheroes in the metalworking world. They make precise cuts with ease, ensuring your projects look sharp—pun intended! These tools are crucial for creating smooth edges and dimensions that fit together nicely. They are commonly used in metal fabrication, like making gears or shafts. Without them, your metal parts might end up looking like abstract art instead of functional pieces!

| Applications | Description |

|---|---|

| Cutting Shafts | Forming clean edges for assembly. |

| Creating Gears | Producing tight tolerances for efficient movement. |

They are essential for anyone serious about machining. As they say, “A good cut today means less sanding tomorrow!”

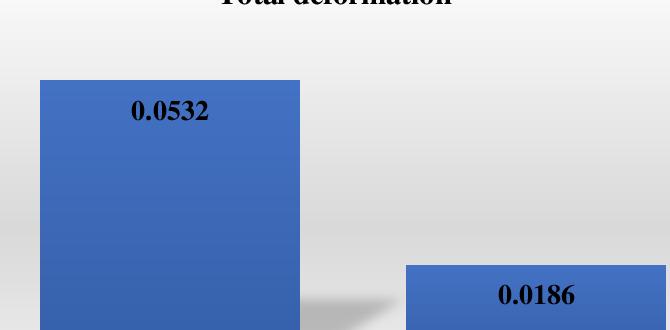

Factors Influencing the Performance of Lathe Parting Tools

Lathe motor compatibility and capabilities. Optimal operating speeds and feed rates.Choosing the right lathe motor can make or break your parting tool performance. A compatible motor ensures smooth operation. If the motor is too weak, you might get the dreaded “stuck tool” dilemma—let’s face it, nobody enjoys wrestling with metal! Speed and feed rates are also crucial. Find that sweet spot to avoid chatter and make chips fly. The right speeds can make your cuts cleaner, just like a hot knife through butter!

| Factor | Importance |

|---|---|

| Lathe Motor Compatibility | Ensures efficient operation |

| Operating Speed | Affects cut quality |

| Feed Rate | Prevents tool binding |

Remember, a good lathe setup is like a perfect sandwich; every ingredient matters!

Maintenance Tips for Longevity of Lathe Parting Tools

Cleaning and storage practices. Resharpening techniques and when to replace.To keep your lathe parting tools in great shape, cleaning is key. Wipe them with a soft cloth after use to remove debris. Store them in a dry place to avoid rust. Regularly resharpen your tools to maintain their sharpness. A good rule is to sharpen when you notice uneven cuts. Lastly, replace tools if they have cracks or chips. This keeps your work accurate and safe!

How often should I resharpen my lathe tools?

Resharpen your lathe tools whenever you notice they start to drag or make rough cuts. Keeping them sharp will ensure clean and precise cuts.

Tips for maintenance:

- Clean tools after each use.

- Store in a dry area.

- Sharpen tools regularly.

Common Issues and Troubleshooting with Lathe Parting Tools

Identifying and solving common cutting problems. Tips for avoiding tool breakage and wear.Using lathe parting tools can feel like trying to slice butter with a wooden spoon—frustrating! Identifying issues is key. If your cut seems off, check the tool angle. A simple tilt can change everything. Tip: Keep your speed steady to avoid tool wear and breakage. Remember, if things go “clang!” too often, something’s not right. To help you out, here’s a quick guide:

| Problem | Solution |

|---|---|

| Uneven cuts | Adjust tool angle |

| Tool wears quickly | Reduce speed |

| Breakage | Check tool material |

Keep these tips in mind, and you won’t need a superhero cape to fix your lathe problems!

DIY vs. Commercially Available Lathe Parting Tools

Pros and cons of making your own tools. When to invest in storebought options.Making your own lathe parting tools can be a fun project. You can save money and customize them to fit your needs. However, it takes time and a bit of skill. If you enjoy tinkering, this could be your next best weekend adventure! But let’s not sugarcoat it—sometimes you just need that shiny tool from the store. If you want reliability without the sweat, investing in a store-bought tool might be wise.

| DIY Tools | Store-Bought Tools |

|---|---|

| Cheaper | Ready to use |

| Customizable | Reliable quality |

| Time-consuming | No learning curve |

Remember, it’s all about your skills and what you need. If you’re building a castle, grab the fancy tools. If you’re putting up a birdhouse, DIY may be your best bet!

Future Trends in Lathe Parting Tool Technology

Innovations in materials and design. Predictions for advancements in metal lathe motors and tools.Exciting changes are ahead for lathe parting tools. Manufacturers are exploring new materials that make tools last longer and cut smoother. Imagine tools so sharp, they could slice through butter!) Innovations in design are also on the rise, making tools easier to handle. In the magical world of motors, we predict breakthroughs will give metal lathe motors more power and efficiency. Like giving a snail a pair of rollerblades, it will zoom through tasks!

| Future Innovations | Expected Advancements |

|---|---|

| New materials | Longer-lasting tools |

| Better design | Easier to use |

| Powerful motors | More efficient cutting |

These advancements promise a bright future for lathe parting tools. Who knows, maybe one day we’ll have robots doing all the work! But until then, let’s enjoy the ride.

Conclusion

In summary, a lathe parting tool helps you cut metal easily on a lathe. The motor powers the tool and helps you make precise cuts. We can make better projects by understanding how these tools work. You can start practicing with your lathe or read more about using parting tools. Hands-on experience will boost your skills!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Parting Tools And Metal Lathe Motors:Sure! A lathe parting tool helps cut pieces of metal from a bigger block. You can think of it like a scissors for metal. The motor on a metal lathe spins the block quickly so the tool can work. This makes cutting easier and faster. It’s important to use the right tool and speed for good results!

Sure! Please ask your question, and I’ll be happy to help you.

What Is The Purpose Of A Parting Tool In A Metal Lathe, And How Does It Differ From Other Cutting Tools?A parting tool is used in a metal lathe to cut through the metal. It helps us make pieces smaller by cutting them off. This tool is different from other cutting tools because it cuts straight down, while others might cut sideways or shape metal. You can think of it like using scissors to cut paper. It makes clean cuts so we can create exactly what we need.

What Are The Key Factors To Consider When Selecting A Parting Tool For Different Materials In Metalworking?When choosing a parting tool in metalworking, think about the material you are cutting. Hard materials need stronger tools to work well. You should also consider the tool’s shape and size for better control. Finally, remember that different materials may require different cutting speeds. These factors help you pick the best tool for the job!

How Does The Power And Torque Of A Metal Lathe Motor Influence The Performance Of A Parting Tool During Operation?The power and torque of a metal lathe motor help control how well the parting tool cuts. When the motor has high power and torque, it can cut faster and smoother. This means the tool won’t get stuck or break easily. If the motor is weak, the tool might struggle and not work as well. So, more powerful motors make cutting easier and better!

What Techniques Can Be Employed To Achieve Clean And Precise Cuts When Using A Parting Tool On A Lathe?To make clean cuts with a parting tool on a lathe, you should try a few simple techniques. First, always keep your tool sharp. A sharp tool cuts better and smoother. Next, use a slow speed on the lathe. This helps you control the cut. Finally, apply gentle pressure as you cut; too much pressure can mess up the shape.

How Do You Troubleshoot Issues Such As Tool Binding Or Chatter When Using A Parting Tool On A Metal Lathe?To fix tool binding or chatter with a parting tool on a metal lathe, check the tool’s sharpness first. A dull tool can bind. If it’s sharp, make sure the tool is set at the right angle. Adjust the speed of the lathe—sometimes slower helps reduce chatter. Lastly, make sure the metal piece is held tight and won’t move.