Have you ever watched a metal lathe in action? It’s like magic! You can create amazing shapes and parts from solid metal. But did you know that a lathe parting tool is a key part of this process? It helps cut off excess metal with ease.

Imagine you have a big block of metal, and you want to turn it into a small part. A lathe parting tool does this job efficiently. It saves time and makes your work look neat. What if you could speed up this process even more? Using a metal lathe with power feed can make your projects even easier.

Power feed assists the tool, moving it automatically. This helps you focus on your crafting instead of worrying about technique. You can create smooth cuts and achieve perfect results. Whether you are a beginner or an expert, this tool helps everyone.

In this article, we will explore how the lathe parting tool works with your metal lathe. We will also look at the benefits of adding a power feed system. Ready to dive in? Let’s uncover the secrets of the lathe world together!

Lathe Parting Tool For Metal Lathe Power Feed Efficiency

Lathe Parting Tool for Metal Lathes with Power Feed

Discover how a lathe parting tool simplifies cutting in metalworking. With its sharp blade, this tool can efficiently slice through materials. Imagine shaping metal like a sculptor with ease! The power feed allows for consistent speed, improving accuracy and reducing user strain. Did you know that using a parting tool can result in cleaner cuts? In short, it’s essential for any metal lathe enthusiast aiming for professional results.Understanding Lathe Parting Tools

Definition and purpose of parting tools in metalworking. Different types of parting tools and their applications.Parting tools are like scissors for metalworking. They help cut off excess material from a workpiece, giving it a neat finish. Imagine trimming a pizza; parting makes your metal project look sharp! There are various types, each with its own superpowers. For instance, some are designed for tough materials, while others are all about speed.

| Type of Tool | Application |

|---|---|

| Standard Parting Tool | General metal cutting |

| Grooving Tool | Creating grooves |

| Angular Parting Tool | Cutting at angles |

So, whether you’re making a tiny robot or a big piece of art, a parting tool is your go-to buddy for clean cuts!

Benefits of Using Power Feed in Metal Lathes

Advantages of power feed over manual feeding. Impact on precision and consistency in parting operations.Using power feed on metal lathes gives you a snack-sized treat of benefits. First, it beats manual feeding every day, like chocolate over broccoli! With power feed, your cuts are sharper and more consistent. No more guessing or uneven parts. This tool lets you focus on the fun stuff, like making your project shine. Plus, your hands get a break from all that cranking. So enjoy smoother operations and better results. Who knew machining could be so relaxing?

| Advantage | Description |

|---|---|

| Increased Precision | Power feed allows for even, steady cuts. |

| Consistency | Every part is made the same size, every time. |

| Less Strain | Your muscles will thank you! |

Choosing the Right Parting Tool for Your Metal Lathe

Factors to consider: material, size, and design. Recommendations for popular parting tools suitable for various projects.Choosing a parting tool for your metal lathe is fun but important. Here are some things to think about:

- Material: Look for tools made of high-speed steel or carbide. They are strong and last longer.

- Size: Match the tool size to your project. Bigger jobs need larger tools.

- Design: Check for a sharp edge and a good shape for easy cutting.

Popular choices for parting tools include:

- HSS Parting Tool – Great for general use.

- Carbide Tipped Tool – Best for tough materials.

- Thin Parting Tool – Perfect for delicate projects.

Finding the right tool will help your projects be more successful.

What factors should I consider?

Consider material, size, and design. These factors affect how well your tool works.

How to Set Up Your Lathe for Parting Operations

Stepbystep guide to adjusting settings for optimal performance. Importance of tool positioning and depth of cut.Setting up your lathe for parting operations involves a few simple steps. First, ensure you have the right tool in place. Adjust the tool position for maximum effectiveness. This means placing the tool close to the workpiece, like a close friend at a party! Next, set the depth of cut carefully. A shallow cut keeps things safe, while a deeper cut offers speed. Remember, too deep is like trying to eat spaghetti with a fork – messy! Follow these steps for smooth, efficient parting:

| Step | Action |

|---|---|

| 1 | Choose the right lathe tool. |

| 2 | Adjust the tool position. |

| 3 | Set the depth of cut. |

| 4 | Start the lathe and check settings. |

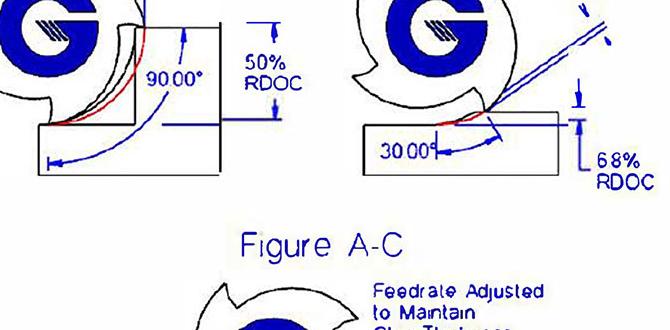

Techniques for Effective Parting Operations

Best practices to ensure smooth cuts and reduce tool wear. Troubleshooting common issues during parting processes.Parting operations can be tricky. To get smooth cuts, follow some best practices. Keep the cutting tool sharp and at the right angle. Use slow, steady movements to avoid tool wear. If the cut feels sticky, try increasing the feed rate. If you see chatter or hear bad noises, check the tool’s position. Remember, proper setup is key to success.

- Keep the tool sharp.

- Use steady pressure.

- Check for proper speed and feed.

- Adjust the tool angle as needed.

What are common issues during parting processes?

Chatter and tool wear are common problems. Proper adjustments or tool replacements can help solve these issues.

Maintaining Your Lathe Parting Tools

Tips for cleaning, sharpening, and storing parting tools. Signs that indicate tools need replacement or repair.Keeping your parting tools in top shape is key to smooth work. First, clean your tools after each use; a soft cloth will do wonders. It’s like giving them a little spa treatment! Next, sharpening is crucial. If your cut feels rough or takes extra effort, it’s time to sharpen those edges. Store your tools in a dry place, safe from bumps—no one likes a clumsy accident. Look for signs like rust or dullness; these mean it’s time for repair or even replacement. Remember, a happy tool makes a happier lathe!

| Signs of Damage | Action Needed |

|---|---|

| Dull edge | Sharpen |

| Rusty surface | Clean or replace |

| Loose parts | Repair |

Safety Considerations When Using Parting Tools

Essential safety gear and precautions to take. Common hazards and how to mitigate them in the shop environment.Using parting tools can be fun, but safety always comes first! Always wear safety goggles to protect your eyes from flying debris. Ear protection is also great, as the noise from machines can be like a rock concert. Don’t wear loose clothing that might get caught. It’s like inviting your shirt to a dangerous dance!

| Safety Gear | Purpose |

|---|---|

| Safety Glasses | Protect eyes from chips |

| Ear Protection | Reduce noise exposure |

| Gloves | Prevent cuts and scrapes |

Watch out for hazards like sharp edges and moving parts. Always keep your workspace tidy. A clean shop is a safe shop! Remember, accidents happen when you aren’t paying attention. Stay alert and have fun parting away!

Frequently Asked Questions about Lathe Parting Tools

Answers to common queries and concerns from users. Expert insights to enhance understanding of parting tools and techniques.Many users wonder how to effectively use lathe parting tools. A common question is, “What is the best feed rate?” The answer is simple: start slow and increase speed as you gain confidence. Another popular inquiry is, “How do I keep my tool sharp?” Regular inspection and honing will help, or as they say, “A sharp tool is a happy tool!”

Not sure what material works best? Use high-speed steel for most tasks. You’ll want to avoid dull tools; they make cutting feel like trying to slice bread with a spoon!

| Question | Answer |

|---|---|

| What feed rate should I use? | Start slow and adjust as needed. |

| How can I keep my parting tool sharp? | Regularly inspect and hone your tool. |

| What material is best for cutting? | High-speed steel works well. |

These tips can boost your confidence. So, don your safety goggles and get ready to part like a pro!

Conclusion

In summary, a lathe parting tool is essential for cutting materials on a metal lathe. Using a power feed makes your work easier and more precise. You can create clean, straight cuts with practice. To improve your skills, try using different tools and techniques. For more tips, consider reading guides or watching tutorial videos online. Happy crafting!FAQs

Here Are Five Related Questions On The Topic Of Lathe Parting Tools And Metal Lathe Power Feed:Sure! A lathe parting tool is used to cut off pieces of metal while it spins on the lathe. You hold the tool steady, and it makes a clean cut. The metal lathe’s power feed helps the tool move smoothly and evenly. This makes your work easier and faster. Always be careful when using these tools!

Sure! Please provide the question you’d like me to answer.

What Is The Purpose Of A Parting Tool In A Metal Lathe Operation, And How Does It Affect The Machining Process?A parting tool is used in a metal lathe to cut off a piece of metal from a larger block. You can think of it as a special knife that makes a clean cut. When we use a parting tool, it helps to shape the metal and create smaller parts. This makes our work easier and gives us better pieces to use in other projects. It helps in finishing the work quickly and neatly.

How Do You Set Up The Power Feed On A Metal Lathe For Optimal Performance While Using A Parting Tool?To set up the power feed on a metal lathe for a parting tool, first, make sure the lathe is turned off. Then, adjust the speed to a lower setting, so it doesn’t go too fast. Next, turn on the power feed switch and select the right feed rate. Keep an eye on how the machine works and stop if it feels too hard. This way, you help the parting tool cut smoothly and safely.

What Factors Should Be Considered When Selecting A Parting Tool For Different Materials Being Machined On A Lathe?When choosing a parting tool for a lathe, think about the material you want to cut. Harder materials need stronger tools. Softer materials can use lighter tools. Also, consider the thickness of the material. A thicker piece might require a wider parting tool for better support. Lastly, make sure the tool’s shape helps you cut smoothly.

How Can Improper Use Of A Parting Tool Impact The Quality Of The Finished Workpiece And The Lathe’S Operational Efficiency?Using a parting tool incorrectly can make your workpiece look rough or messy. It might create deep scratches or uneven edges. This can waste time because you’ll need to fix those mistakes. Plus, it can slow down the lathe, making it harder to use. Overall, being careful with the tool helps you make better projects faster.

What Are The Safety Precautions To Take When Using A Parting Tool With The Power Feed On A Metal Lathe?When using a parting tool on a metal lathe, always wear safety goggles. Make sure your hair and clothes are tied back. Keep your hands away from the cutting area. Never leave the lathe running unattended. Finally, turn off the machine when you finish and before changing tools.