Have you ever wondered how metal parts are shaped with perfect precision? The magic often happens with a lathe. Among the many tools used, the lathe parting tool plays a crucial role. It helps cut pieces away from larger metal blocks smoothly and accurately.

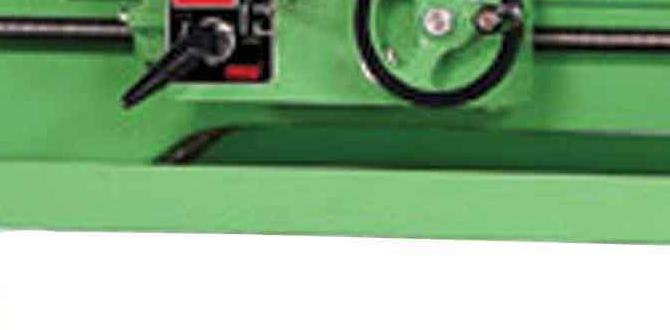

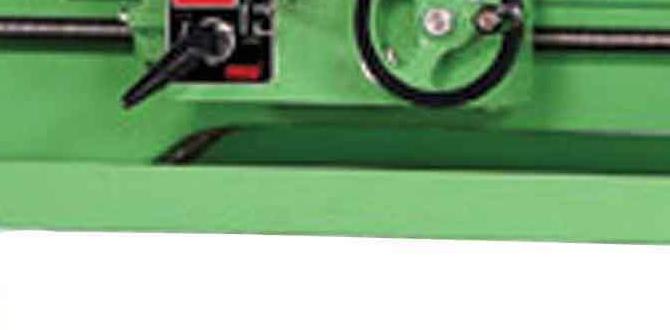

Imagine you’re looking at a finished metal part. Every curve and edge looks perfect, right? That’s because skilled workers use the lathe and its parting tool to create these shapes. But what exactly is a metal lathe saddle? The saddle is the part of the lathe that supports the cutting tool. Without it, shaping metal would be much harder.

Did you know that a simple mistake with a lathe parting tool can ruin an entire project? That’s why many people rely on these tools so much. They ensure that everything is done neatly. So, are you ready to learn more about how a lathe parting tool works and why it’s so important? Let’s dive into the world of metal lathes and discover the secrets behind them!

Lathe Parting Tool For Metal Lathe Saddle: A Comprehensive Guide

Discovering the Lathe Parting Tool for Metal Lathe Saddle

The lathe parting tool is essential for metalworking. It helps cut and shape materials with precision, making it easier for hobbyists and professionals alike. Imagine you are creating a beautiful metal piece. A parting tool allows you to insert cuts into your metal without much hassle. Did you know parting tools come in various shapes and sizes? Understanding how to use this tool effectively can improve your crafting skills significantly. Get ready to make amazing projects!Understanding Lathe Parting Tools

Definition and purpose of parting tools in metal lathes. Importance in manufacturing and machining processes.Parting tools are special tools used on metal lathes. Their job is to cut pieces off larger metal shapes. Think of it like cutting slices from a loaf of bread. This process is important in making many items we use, from car parts to kitchen tools. With the right parting tool, manufacturers can work faster and make cleaner cuts. This helps create better products and saves time.

What are the uses of parting tools?

Parting tools help create precise cuts, separate materials, and shape products perfectly.

Benefits of parting tools:

- Improves accuracy

- Saves time

- Enhances product quality

Choosing the Right Parting Tool for Your Project

Factors to consider (material type, tool height, width). Recommendations based on specific metal lathe projects.Finding the right parting tool matters for your metal lathe project. Start by thinking about the material type you need to cut. Tough metals require stronger tools. Next, consider the tool height. It should match your lathe height for smooth operation. The width is also key; wider tools make thicker cuts. For example:

- Aluminum: A narrow tool works best.

- Steel: Use a medium-width tool for accuracy.

- Brass: A wider tool gives better results.

Choosing wisely will make your work easier.

What factors should I consider?

Think about material type, tool height, and width. Each factor helps in making precise cuts and achieving better finishes.

Setup and Installation of Parting Tools

Stepbystep instructions for installing parting tools on a metal lathe. Tips for aligning and adjusting tools for optimal performance.Installing parting tools on your metal lathe doesn’t have to feel like rocket science. First, secure the toolholder to the lathe. Check that it’s snug, but don’t crank it down like you’re trying to impress a stubborn jar lid! Next, slide in the parting tool. Align the tool with the workpiece; it should be perfectly straight like a well-behaved pencil. Adjust the height until it’s at the centerline of the workpiece. A good tip: use a steel rule or caliper for precise measuring.

| Step | Action |

|---|---|

| 1 | Secure the toolholder snugly |

| 2 | Slide in the parting tool |

| 3 | Align it with the workpiece |

| 4 | Adjust height to centerline |

Check for any loose parts before starting. It’s like checking for your homework—nobody wants that last-minute panic! Proper alignment will ensure smooth cuts. With practice, you’ll feel like a lathe superhero. So, put on that apron, and let’s get cutting!

Techniques for Effective Parting

Best practices for parting operations. Common mistakes and how to avoid them.Parting is an important step in using a lathe. Following the best practices makes this task easier. Here are some tips:

- Always use sharp tools. Dull tools can cause mistakes.

- Keep the correct speed. Too fast can lead to breakage.

- Make sure the tool is set at the right angle for cutting.

Some common mistakes happen when people rush. They might push too hard or forget to check the tool’s position. Avoid these errors by taking your time and following your plan closely.

What are the best practices for parting operations?

Best practices include using sharp tools, checking speed, and positioning tools properly.

Common mistakes and how to avoid them:

- Rushing the process – take your time.

- Pushing too hard – let the tool do the work.

- Not checking the tool position – double-check before cutting.

Maintenance of Lathe Parting Tools

Regular care and cleaning procedures to extend tool life. Techniques for sharpening and replacing blades.To keep your lathe parting tools in top shape, it’s important to give them some love and care. Regular cleaning helps keep grime at bay, making them sharper and happier. Try a simple wipe down after each use. Sharpening your blades is like giving your tools a new haircut—it helps them work better! Use a sharpening stone or a specialized tool sharpener. And remember, if a blade is more tired than a puppy after a long walk, it’s time to replace it. A well-kept tool is a happy tool!

| Maintenance Task | Frequency |

|---|---|

| Clean Tools | After Each Use |

| Sharpen Blades | Every Few Uses |

| Replace Blades | As Needed |

Safety Considerations When Using Parting Tools

Essential safety gear and precautions. Procedures to follow to ensure safe operation.Using parting tools safely is very important. Always wear the right safety gear. This includes goggles, gloves, and a face shield. These items protect you from flying chips and sharp edges.

Follow these steps for safe operation:

- Check your tool and machine before use.

- Keep your work area clean and organized.

- Make sure the tool is securely attached.

- Stand to the side when starting the machine.

These precautions help keep everyone safe. Remember, being careful is always smart!

What personal safety gear should be used for parting tools?

Your personal safety gear should include goggles, gloves, and ear protection. These items keep you safe while you work.

Common Issues and Troubleshooting

Identifying common problems faced when using parting tools. Solutions and adjustments to improve performance.Using parting tools can come with a few problems. Here are some common issues you might face:

- Tool chatter, causing uneven cuts.

- Too much heat, leading to blunt tools.

- Incorrect feed rate, which can break the tool.

To improve performance, try these solutions:

- Adjust the speed to reduce chatter.

- Keep tools cool with cutting fluid.

- Set the right feed rate to avoid breaks.

What are common problems with parting tools?

Common problems include tool chatter, overheating, and wrong feed rates. These can lead to poor cuts and damaged tools.

How can performance improve?

Adjusting speed, cooling tools, and setting the right feed rate can help greatly. Small changes make a big difference!

Innovations in Parting Tool Technology

Latest advancements in parting tool design and materials. Future trends in lathe technology and their impact on parting tools.Parting tools have come a long way! New designs focus on sharpness and durability, using advanced materials like carbide. This makes cutting faster and cleaner. Imagine slicing through metal like a hot knife through butter! Experts predict that future lathe technology will introduce smart features, like sensors that adjust tool speed automatically. This means smoother operations and less time spent fixing mistakes—so say goodbye to the “oops” moments! Check out the table below to see some cool innovations.

| Innovation | Description |

|---|---|

| Carbide Tips | Stronger and longer-lasting, these tips cut through metal with ease. |

| Smart Tech | Tools with sensors for real-time adjustments make machining smarter. |

| Ergonomic Design | Handles and grips for comfort reduce operator fatigue. |

Conclusion

In summary, a lathe parting tool is essential for cutting metal on a lathe saddle. It helps you make precise cuts and smooth edges. Understanding how to use this tool improves your metalworking skills. We encourage you to practice with a parting tool and explore more about lathe techniques to enhance your projects. Happy turning!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Parting Tools And The Metal Lathe Saddle:A lathe parting tool is a sharp tool we use on a lathe. It helps you cut pieces of metal into smaller parts. The metal lathe saddle is a part of the lathe that holds everything steady. You adjust it to help move the cutting tool. Together, they help you make neat shapes in metal!

Sure! Please give me the question you want me to answer, and I’ll help you with it.

What Is The Purpose Of A Parting Tool In Metal Lathe Operations, And How Does It Differ From Other Cutting Tools?A parting tool is used to cut off a piece of metal from a bigger block or rod. We use it to make clean breaks. Unlike other cutting tools, a parting tool is thin and straight. It helps us separate parts instead of shaping them. This makes it special for cutting rather than carving or shaping.

How Do You Properly Set Up The Parting Tool On A Metal Lathe Saddle To Ensure Accurate And Safe Cutting?To set up the parting tool on the metal lathe, start by turning off the machine. Then, adjust the tool holder so the parting tool is level and fits snugly. Make sure the tool is close to the workpiece but not touching it. Finally, check that the tool is secure before you begin cutting. Always wear safety gear while working.

What Materials Are Commonly Used For Parting Tools, And How Do Their Properties Affect Cutting Performance?Common materials for parting tools include high-speed steel, carbide, and ceramic. High-speed steel is tough, so it lasts a long time. Carbide is harder and can cut faster but can break easily. Ceramic tools are very strong and stay sharp but can be brittle. Each material affects how fast and smooth we can cut things.

What Are The Common Issues Encountered When Using A Parting Tool On A Metal Lathe, And How Can They Be Resolved?When using a parting tool on a metal lathe, you might have a few problems. First, the tool can chatter, making a loud noise. This happens if the tool is not sharp or if you’re cutting too fast. To fix it, you can use a sharper tool and slow down your speed. Also, sometimes the piece might bind, which means it gets stuck. You can stop and check if everything is lined up correctly.

How Can The Design And Adjustment Of The Lathe Saddle Influence The Effectiveness Of Parting Operations On Various Metal Types?The lathe saddle holds the cutting tool steady. If it’s designed well, it can cut through metal easily. You can adjust it for different metals, like soft or hard ones. This makes the cutting smoother and faster. If we don’t adjust it right, cutting can be hard and take longer.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Parting Tools And The Metal Lathe Saddle:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A lathe parting tool is a sharp tool we use on a lathe. It helps you cut pieces of metal into smaller parts. The metal lathe saddle is a part of the lathe that holds everything steady. You adjust it to help move the cutting tool. Together, they help you make neat shapes in metal!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please give me the question you want me to answer, and I’ll help you with it.”}},{“@type”: “Question”,”name”: “What Is The Purpose Of A Parting Tool In Metal Lathe Operations, And How Does It Differ From Other Cutting Tools?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A parting tool is used to cut off a piece of metal from a bigger block or rod. We use it to make clean breaks. Unlike other cutting tools, a parting tool is thin and straight. It helps us separate parts instead of shaping them. This makes it special for cutting rather than carving or shaping.”}},{“@type”: “Question”,”name”: “How Do You Properly Set Up The Parting Tool On A Metal Lathe Saddle To Ensure Accurate And Safe Cutting?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up the parting tool on the metal lathe, start by turning off the machine. Then, adjust the tool holder so the parting tool is level and fits snugly. Make sure the tool is close to the workpiece but not touching it. Finally, check that the tool is secure before you begin cutting. Always wear safety gear while working.”}},{“@type”: “Question”,”name”: “What Materials Are Commonly Used For Parting Tools, And How Do Their Properties Affect Cutting Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common materials for parting tools include high-speed steel, carbide, and ceramic. High-speed steel is tough, so it lasts a long time. Carbide is harder and can cut faster but can break easily. Ceramic tools are very strong and stay sharp but can be brittle. Each material affects how fast and smooth we can cut things.”}},{“@type”: “Question”,”name”: “What Are The Common Issues Encountered When Using A Parting Tool On A Metal Lathe, And How Can They Be Resolved?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a parting tool on a metal lathe, you might have a few problems. First, the tool can chatter, making a loud noise. This happens if the tool is not sharp or if you’re cutting too fast. To fix it, you can use a sharper tool and slow down your speed. Also, sometimes the piece might bind, which means it gets stuck. You can stop and check if everything is lined up correctly.”}},{“@type”: “Question”,”name”: “How Can The Design And Adjustment Of The Lathe Saddle Influence The Effectiveness Of Parting Operations On Various Metal Types?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The lathe saddle holds the cutting tool steady. If it’s designed well, it can cut through metal easily. You can adjust it for different metals, like soft or hard ones. This makes the cutting smoother and faster. If we don’t adjust it right, cutting can be hard and take longer.”}}]}