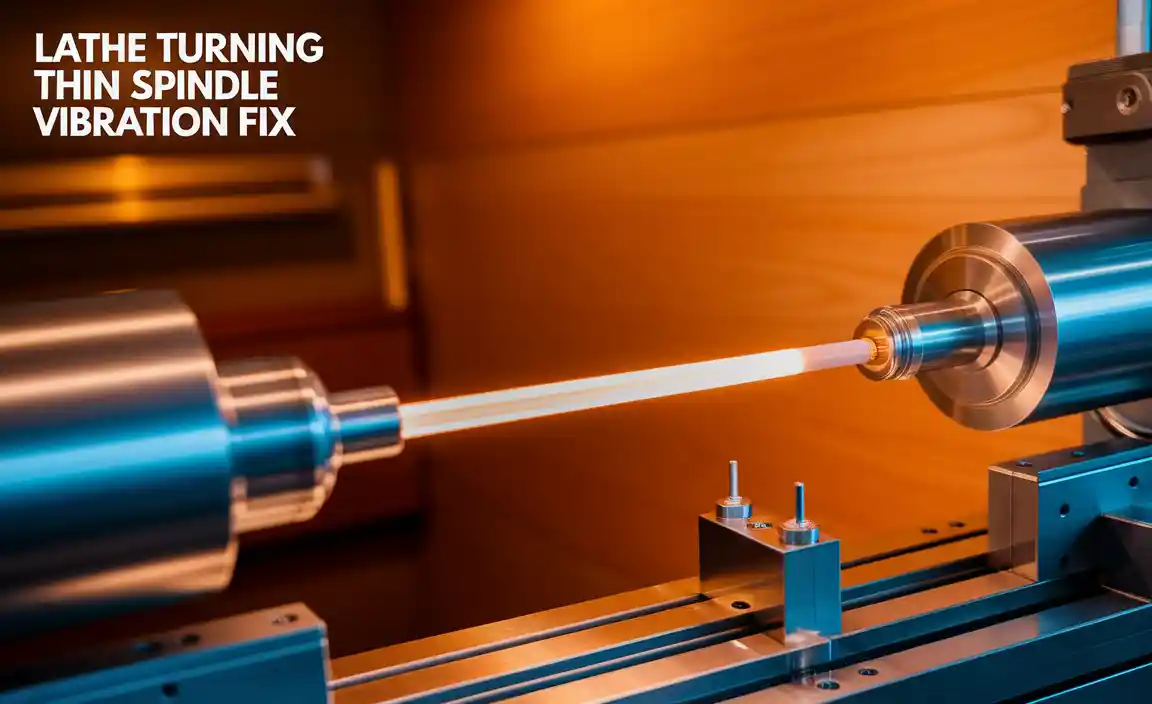

Are you looking to improve your metal lathe skills? Upgrading your tools can make a huge difference. One of the most important tools for metalworking is the lathe parting tool. It helps you cut materials easily and cleanly.

Imagine this: you’re working on a project, and you need to create precise cuts. A fine lathe parting tool ensures you don’t waste time or ruin your work. Isn’t it frustrating when tools just don’t perform? With the right upgrade, you can say goodbye to those problems.

Here’s a fun fact: switching to a better parting tool can save you hours of work. If you want success in your metal lathe projects, upgrading your lathe parting tool is a smart choice. You’ll feel proud of the results and enjoy the process so much more!

Upgrade Your Metal Lathe With A Lathe Parting Tool

Discovering Lathe Parting Tool Upgrades for Your Metal Lathe

Upgrading your metal lathe with a lathe parting tool can change how you work. These tools help you cut materials easily and make clean edges. This upgrade enhances your projects by improving accuracy and speed. Did you know that a high-quality parting tool can save you hours? Many users find that it boosts their creativity and confidence. With the right tool in hand, you’ll tackle any project like a pro!Understanding Lathe Parting Tools

Definition and purpose of parting tools. Different types of parting tools used in metal lathes.Parting tools are special devices used on lathes. Their main job is to cut materials into smaller pieces. These tools help create grooves and slots in metal. This makes them super handy for many projects! Here are a few types of parting tools:

- Standard Parting Tool: Regular tool for basic cuts.

- Diamond Parting Tool: Great for fine, precise cuts.

- Negative Rake Tool: Works well for harder metals.

Each kind has a special use, making parting tools very important in metal work.

What is the purpose of parting tools?

The purpose of parting tools is to cut materials into smaller parts. They help the metal lathe make clear and clean cuts.

How many types of parting tools are there?

There are a few types of parting tools. Some common ones include:

- Standard Parting Tool

- Diamond Parting Tool

- Negative Rake Tool

Why Upgrade to a High-Quality Parting Tool?

Benefits of using an upgraded parting tool. Impact on precision and finish quality.Upgrading to a high-quality parting tool can work wonders for your lathe projects. First, it offers better precision for cutting, making your pieces fit together smoothly—like peanut butter and jelly! A good tool helps you achieve a gorgeous finish, transforming rough edges into a sight for sore eyes. Want a satisfied smile every time you use your lathe? The right parting tool is your secret weapon!

| Benefit | Impact |

|---|---|

| Better Precision | Fits parts perfectly, reducing frustration. |

| Smooth Finish | Eliminates rough edges, looks professional. |

Choosing the Right Parting Tool for Your Metal Lathe

Factors to consider: size, material, and design. Popular brands and models in the market.Finding the right parting tool for your metal lathe is key to smooth cutting. Think about these important factors:

- Size: The tool must fit your lathe perfectly.

- Material: High-speed steel or carbide are great options.

- Design: Choose a shape that matches your work needs.

Several brands offer quality tools. Popular ones include:

- HSS Cutting Tools

- Grizzly Industrial

- MSC Industrial Supply

These brands have a variety of models to suit different projects.

What is a good parting tool for a metal lathe?

A good parting tool should be sharp, sturdy, and easy to use. Look for brands like Grizzly and HSS for reliable options.

Installation Process of a Lathe Parting Tool

Stepbystep guide to installing a parting tool. Common mistakes to avoid during installation.To install a lathe parting tool, follow these simple steps:

- First, turn off the lathe machine and unplug it for safety.

- Next, remove the old tool if there is one.

- Then, adjust the tool holder to fit the new parting tool.

- Tighten the screws to secure the tool in place.

- Finally, double-check the alignment before powering on the lathe.

Watch out for common mistakes like not securing the tool tightly or misaligning it. These can lead to poor cuts and safety issues. Always read the manual, too!

What are common mistakes when installing a parting tool?

Common mistakes include misalignment of the tool and incomplete tightening. Both can cause problems. Always ensure that the tool is level and securely fastened to avoid errors.

Techniques for Efficient Use of Parting Tools

Best practices for cutting with parting tools. Tips for maintaining tool sharpness and longevity.Using parting tools can be tricky, but with the right techniques, you can cut great shapes. First, make sure your tool is sharp. A dull tool can break or chip the metal. Next, use steady pressure while cutting. This helps create a clean cut. Maintain adequate lubrication to reduce heat. Lastly, keep the tool at a proper angle. This improves control and accuracy. Follow these tips and you’ll get better results!

How can I keep my parting tool in good shape?

To keep your parting tool sharp and lasting longer, remember these tips:

- Regularly sharpen your tool to maintain its edge.

- Store it safely to prevent damage.

- Clean your tool after use to prevent rust.

Common Problems and Solutions with Parting Tools

Typical issues encountered when using parting tools. Troubleshooting tips and remedies for effective operation.Using parting tools can be tricky. You might find them binding or breaking. This can cause frustration, like trying to untangle headphones! To prevent these issues, make sure your tool is sharp and correctly positioned. Keep the speed low and the feed steady for better results. If your lathe begins to chatter, check for tightness. Here’s a quick table of common problems and fixes:

| Problem | Solution |

|---|---|

| Tool binding | Adjust tool height |

| Chatter | Lower speed |

| Tool breakage | Use sharp tools |

With these tips, you’ll have better luck with your parting tool. Soon, you’ll be parting like a pro, and maybe even impressing your friends with your skills!

Comparing Traditional vs. Modern Parting Tools

Key differences between traditional and contemporary designs. Advantages of modern parting tools in metalworking.Traditional parting tools often use simple shapes and designs. They can be slow and hard to control. Modern parting tools have advanced shapes and materials for better results. These tools can cut faster and with more precision. Here are some key differences:

- Design: Traditional tools are basic; modern tools are ergonomic.

- Speed: Modern tools cut metal quickly; traditional tools take longer.

- Material: New tools use tougher materials, lasting longer.

- Control: Modern tools offer better handling and easier use.

Modern tools can greatly improve metalworking efficiency. Using them can help save time and effort. Many experts recommend upgrading to these advanced tools for better results.

What makes modern parting tools better?

Modern parting tools offer faster cutting speeds, better precision, and improved durability compared to traditional tools.Benefits of Modern Parting Tools:

- Enhanced cutting efficiency

- Safer and easier to use

- Longer tool life

Real-Life Applications of Parting Tools in Metalworking

Examples of projects where parting tools are essential. User testimonials and case studies.Parting tools are super important in many metalworking projects. They help cut metal pieces smoothly and accurately. Here are a few projects where parting tools shine:

- Making custom metal parts for machines.

- Creating beautiful jewelry from metal.

- Building tool handles from raw materials.

- Preparing metal rods for welding.

Users say these tools improve their work. One metalworker reported, “Upgrading my lathe with a parting tool made my cuts cleaner and faster!” Another said, “It made working on my projects so much easier!” Parting tools clearly help metalworkers accomplish amazing things!

What are real-life uses of parting tools?

Parting tools are crucial for creating different metal shapes and parts. They make projects easier and more precise!

Frequently Asked Questions about Lathe Parting Tools

Common inquiries about specifications and usage. Expert answers to enhance understanding and application.Many people have questions about lathe parting tools. Here are some common ones:

What is a lathe parting tool?

A lathe parting tool is a special tool used to cut materials. It helps create sharp edges or separate pieces in metalworking.

How do I choose the right parting tool?

To choose the right parting tool, consider:

- Material: What type of metal will you cut?

- Width: Choose a width that fits your project.

- Quality: Invest in a good tool for better results.

Can I use a parting tool on all metals?

No, some tools are better for softer metals, while others work best for harder ones.

How do I maintain my parting tool?

Keep your tool sharp and clean. This ensures it cuts well and lasts longer.

Conclusion

In summary, upgrading your lathe parting tool can improve cutting performance and provide cleaner finishes. When choosing a tool, consider materials and design for better results. This simple upgrade can make your metalworking easier and more enjoyable. Try researching different tools or ask experts for advice to find the best option for your projects. Happy cutting!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Parting Tools And Metal Lathe Upgrades:Sure! Here are five related questions about lathe parting tools and metal lathe upgrades: 1. What are lathe parting tools? Lathe parting tools are sharp tools used to cut off extra metal from a piece. They help shape the metal. 2. Why might you need to upgrade your metal lathe? You might upgrade your metal lathe to work faster or to make better shapes. New parts can make it easier. 3. How do you use a parting tool? You use a parting tool by pressing it against the metal while the lathe spins. It cuts through the metal. 4. What is the benefit of a better parting tool? A better parting tool helps you make clean cuts. This means your work looks nicer and is easier to finish. 5. Can you change parts on a metal lathe? Yes, you can change parts on a metal lathe. This can help it work better and fit your needs.

Of course! Please provide the question you would like me to answer.

What Are The Key Features To Look For When Upgrading Parting Tools For A Metal Lathe?When upgrading parting tools for a metal lathe, look for strong materials. High-speed steel (HSS) or carbide are good choices. You also want tools with a good cutting edge. A sharp edge helps cut better and last longer. Finally, check if the tool fits your lathe properly. A good fit keeps everything safe and working well.

How Do Different Materials (Such As Carbide Vs. High-Speed Steel) Affect The Performance Of A Parting Tool?Different materials can change how well a parting tool works. Carbide tools are strong and last a long time. They cut through metal easily and stay sharp. High-speed steel tools are easier to sharpen but wear out faster. So, if you want your tool to last, carbide is usually better!

What Common Problems Can Arise When Using A Parting Tool On A Metal Lathe, And How Can Upgrades Help Mitigate These Issues?When using a parting tool on a metal lathe, you might face problems like tool breakage or rough cuts. This happens when the tool gets too hot or if it’s not sharp enough. Upgrading to better tools or using a cooler cutting fluid can help. These changes keep the tool sharp and reduce heat, making your cuts smoother and safer.

Are There Specific Brands Or Models Of Parting Tools That Are Highly Recommended For Metal Lathe Applications?Yes, there are good brands for parting tools. You can try brands like HSS (High-Speed Steel) or carbide tools. Some popular models include the HSS parting tool and the Ceratip parting tool. These are strong and help you cut metal easily. Always ask a teacher or an adult for help when using them!

How Can The Geometry Of A Parting Tool Influence Its Efficiency And Chip Removal During Machining?The shape of a parting tool affects how well it cuts and removes metal. If the tool is sharp and narrow, it slices through material easily. This helps to create chips, which are the small pieces of metal that come off. Good chip removal keeps the area clear, so the tool can work better and faster. A well-designed tool makes the job easier and helps us finish tasks quicker.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Parting Tools And Metal Lathe Upgrades:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five related questions about lathe parting tools and metal lathe upgrades: 1. What are lathe parting tools? Lathe parting tools are sharp tools used to cut off extra metal from a piece. They help shape the metal. 2. Why might you need to upgrade your metal lathe? You might upgrade your metal lathe to work faster or to make better shapes. New parts can make it easier. 3. How do you use a parting tool? You use a parting tool by pressing it against the metal while the lathe spins. It cuts through the metal. 4. What is the benefit of a better parting tool? A better parting tool helps you make clean cuts. This means your work looks nicer and is easier to finish. 5. Can you change parts on a metal lathe? Yes, you can change parts on a metal lathe. This can help it work better and fit your needs.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Of course! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Features To Look For When Upgrading Parting Tools For A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When upgrading parting tools for a metal lathe, look for strong materials. High-speed steel (HSS) or carbide are good choices. You also want tools with a good cutting edge. A sharp edge helps cut better and last longer. Finally, check if the tool fits your lathe properly. A good fit keeps everything safe and working well.”}},{“@type”: “Question”,”name”: “How Do Different Materials (Such As Carbide Vs. High-Speed Steel) Affect The Performance Of A Parting Tool?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different materials can change how well a parting tool works. Carbide tools are strong and last a long time. They cut through metal easily and stay sharp. High-speed steel tools are easier to sharpen but wear out faster. So, if you want your tool to last, carbide is usually better!”}},{“@type”: “Question”,”name”: “What Common Problems Can Arise When Using A Parting Tool On A Metal Lathe, And How Can Upgrades Help Mitigate These Issues?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a parting tool on a metal lathe, you might face problems like tool breakage or rough cuts. This happens when the tool gets too hot or if it’s not sharp enough. Upgrading to better tools or using a cooler cutting fluid can help. These changes keep the tool sharp and reduce heat, making your cuts smoother and safer.”}},{“@type”: “Question”,”name”: “Are There Specific Brands Or Models Of Parting Tools That Are Highly Recommended For Metal Lathe Applications?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there are good brands for parting tools. You can try brands like HSS (High-Speed Steel) or carbide tools. Some popular models include the HSS parting tool and the Ceratip parting tool. These are strong and help you cut metal easily. Always ask a teacher or an adult for help when using them!”}},{“@type”: “Question”,”name”: “How Can The Geometry Of A Parting Tool Influence Its Efficiency And Chip Removal During Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The shape of a parting tool affects how well it cuts and removes metal. If the tool is sharp and narrow, it slices through material easily. This helps to create chips, which are the small pieces of metal that come off. Good chip removal keeps the area clear, so the tool can work better and faster. A well-designed tool makes the job easier and helps us finish tasks quicker.”}}]}