Have you ever wondered how metal and wood can be shaped into amazing objects? Using a lathe is one of the best ways to do this. But why do we need different tools for metal lathes and wood lathes? Each lathe has its own special skills. Imagine making a beautiful wooden bowl versus a sturdy metal part. The right lathe parting tool can make all the difference.

In the world of crafting, knowing the differences can help you become a better maker. Did you know that the tool you use can change how your project turns out? It’s true! It’s like choosing between crayons and paint. Each has its unique strengths.

Join us as we explore the exciting world of lathe parting tools. We will uncover what makes metal lathe tools different from wood lathe tools. You might be surprised by the things you learn!

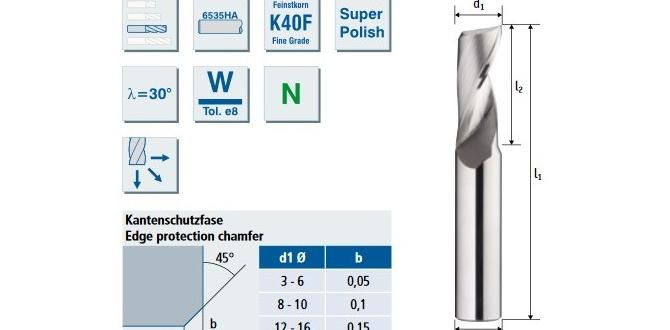

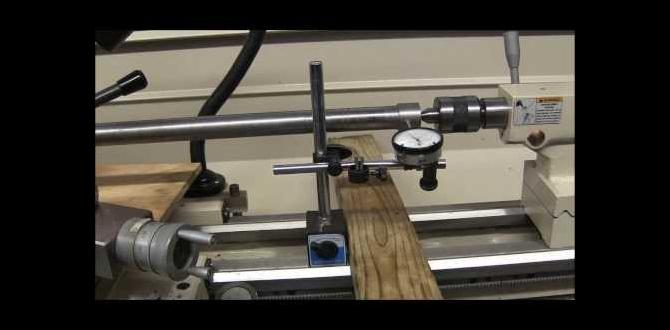

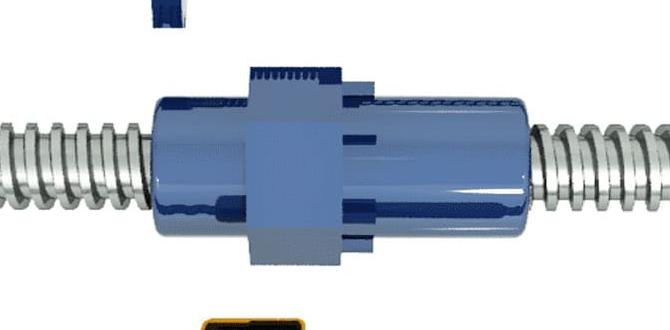

Lathe Parting Tool: Metal Lathe Vs Wood Lathe Comparison The Choice Between A Metal Lathe And A Wood Lathe Is Crucial For Any Machinist Or Woodworker Looking To Utilize A Lathe Parting Tool Effectively. Each Type Has Its Distinct Features, Advantages, And Applications That Cater To Different Project Needs. In This Article, We Will Explore The Differences And Similarities Between Metal Lathes And Wood Lathes When It Comes To Using Parting Tools, Thereby Helping You Make An Informed Decision. Understanding Lathe Types **Metal Lathes** Are Designed For Machining Metals And Are Generally More Robust And Powerful Than Wood Lathes. They Are Capable Of Handling Tougher Materials, Providing Greater Precision In Shaping And Cutting. Their Design Typically Includes Features Such As A Tailstock, A Carriage For Moving The Workpiece, And Various Tool Holders, Allowing The Use Of Specialized Tools, Including Parting Tools. **Wood Lathes**, On The Other Hand, Are Specifically Built For Shaping Wood. They Tend To Be Simpler In Design And Generally Lighter Than Metal Lathes, As They Don’T Need To Exert The Same Level Of Force As Metalworking Lathes. The Tools Used On A Wood Lathe, Including Parting Tools, Are Often Designed To Accommodate The Softer Nature Of Wood, Focusing On Finesse Rather Than Brute Strength. Lathe Parting Tool: Functionality A **Lathe Parting Tool** Is An Essential Tool For Both Metal And Wood Lathes, Used Primarily To Create A Narrow Cut Or Groove In The Workpiece. This Is Particularly Useful When Making Precise Cuts, Separating Materials, Or When The Next Step In A Project Involves Removing Segments. When Discussing **Metal Lathe Vs Wood Lathe**, The Functionality Of The Parting Tool Can Vary: – **In Metal Lathes**: Parting Tools Are Typically Made From High-Speed Steel Or Carbide-Tipped Materials, Designed To Withstand The Significant Forces Involved When Cutting Through Metal. The Parting Tool’S Geometry Is Crafted For Efficient Cutting, Reducing The Chance Of Tool Breakage Or Damage. – **In Wood Lathes**: The Parting Tool Is Often Made From Steel And Features A Sharp, Thin Blade For Clean Cuts. Since Wood Is Less Dense Than Metal, The Pressure Applied Is Significantly Lower, Allowing For More Delicate Maneuvers And Smoother Finishes. Choosing The Right Lathe When Deciding On A Lathe For Your Workshop, Consider The Type Of Projects You Plan To Undertake. If You Primarily Work With Metals And Need A High Degree Of Precision, A Metal Lathe Would Be The Better Choice, Complemented By A Robust Parting Tool. However, For Woodworking Projects, A Wood Lathe, Optimized For Smooth Finishes And Ease Of Use, Along With A Suitable Parting Tool, Will Suffice. Conclusion In Conclusion, The Comparison Of **Metal Lathe Vs Wood Lathe** Showcases The Need For Selecting The Right Tools For Specific Materials And Projects. Regardless Of The Type Of Lathe You Choose, The Lathe Parting Tool Remains A Pivotal Component In The Machining Process, Delivering Accurate And Clean Results. Understanding The Differences In How These Lathes Operate Will Lead To Better Outcomes In Your Crafting Endeavors.

Lathe Parting Tool: Metal Lathe vs Wood Lathe

When comparing lathe parting tools for metal lathes and wood lathes, users discover various key differences. Metal lathes often require sharper and stronger cuttings tools, while wood lathes prioritize softer, rounded edges. Did you know that wood lathes can create beautiful, intricate designs? In contrast, metal lathes focus on precise cuts for engineering projects. Choosing the right tool enhances your crafting experience, so what will you create next?Understanding Lathe Parting Tools

Definition and purpose of parting tools. Differences between parting tools for metal and wood lathes.Parting tools are special tools used on lathes. They help cut materials into smaller pieces. Think of them as the scissors of the lathe world! For metal lathes, parting tools are usually made from harder materials to handle tough metals. Wood lathes, on the other hand, use blades that are sharp yet flexible to slice through soft woods. You wouldn’t use a chainsaw to trim your hair, right? It’s all about having the right tool for the job!

| Tool Type | Material | Use |

|---|---|---|

| Metal Lathe | Harder Materials | Cut Tough Metals |

| Wood Lathe | Sharp, Flexible Blades | Slice Soft Woods |

Types of Lathe Parting Tools

Straight vs. beveled parting tools. Material differences: Highspeed steel vs. carbide inserts.Parting tools come in different shapes and styles. You have straight tools that look as simple as a pencil and beveled tools that have a cool angled edge. Each works best for different tasks. Materials matter too! High-speed steel can be sharp and last a while, while carbide inserts are like superheroes, tough and super-durable. Choose the right tool, and you’ll have parts flying off your lathe like pancakes from a flipping contest!

| Type | Material | Durability | Best For |

|---|---|---|---|

| Straight | High-speed steel | Good | General use |

| Beveled | Carbide inserts | Excellent | Hard materials |

Metal Lathe Parting Tools

Features and specifications of metal lathe parting tools. Techniques for using parting tools on metal lathes.Metal lathes use parting tools to cut through metal with ease. These tools are sharp and precise, allowing for clean cuts. The features typically include a sturdy body, adjustable cutting angles, and a narrow blade for detailed work. Techniques for using these tools are crucial. First, make sure the lathe is properly set up. Second, apply a light pressure while moving the tool. Remember, less pressure is often more effective. It’s like trying to slice through butter; too much force and it just squishes!

| Feature | Specification |

|---|---|

| Blade Material | High-speed steel or carbide |

| Width | 1/16″ to 1/4″ |

| Dimensions | Varies by lathe model |

To use a parting tool, start at a slow speed. Gradually increase as needed. The secret is to listen; if you hear too much noise, you might need to adjust. With practice, you’ll be the master of metal like a knight wielding a sword!

Wood Lathe Parting Tools

Characteristics of wood lathe parting tools. Best practices for using parting tools on wood lathes.Wood lathe parting tools are narrow and sharp. They help in cutting away wood safely. Good parting tools can make smooth cuts. Here are some best practices for using them:

- Always keep the tool sharp.

- Use a steady hand while cutting.

- Work at a slow speed for better control.

- Practice on scrap wood before working on your project.

Remember, safety should always come first. A good tool can make a big difference in your woodwork!

What should I know about wood lathe parting tools?

Wood lathe parting tools help create clean cuts and are ideal for shaping wood pieces.

Choosing the Right Parting Tool

Factors to consider when selecting a parting tool for metal vs. wood lathes. Cost and availability of parting tools.Picking the right parting tool can be like choosing the best candy in a store—so many options! Metal lathes and wood lathes need different tools. Metal parting tools are often tougher, while wood parting tools are lighter and quicker to use. Consider the cost too; metal tools might be pricier but can last longer. Make sure the tool is easy to find, because who wants to wait for a part like it’s a slow-moving snail?

| Factor | Metal Lathe Tool | Wood Lathe Tool |

|---|---|---|

| Durability | High | Medium |

| Cost | Higher | Lower |

| Availability | Common | Very Common |

Maintenance and Care for Parting Tools

Cleaning and sharpening parting tools. Storage tips for longevity and performance.Parting tools need some love to work their best. Clean them gently after use. A soft cloth will do the trick, just like giving your dog a nice rub! Sharpening is important too. Keep them sharp for smooth cutting. Store them safely in a dry place, away from moisture. This helps them last longer. It’s like giving them a cozy bed to sleep in. Check out the table below for more tips!

| Care Tips | Description |

|---|---|

| Clean | Wipe with a soft cloth after use. |

| Sharpen | Use a sharpening stone or file regularly. |

| Store | Keep in a dry place, away from dampness. |

With these tips, your tools will be happy and ready for action! Who knew maintenance could be so easy and fun?

Common Challenges and Solutions

Issues faced while parting on metal vs. wood lathes. Recommended troubleshooting techniques and solutions.Using a lathe can be tricky, both for metal and wood. Each material has its own quirks. Metal lathes often face problems like chatter and tool wear. Wood lathes might struggle with tearing or snagging. To fix these, you can adjust the speed and feed rate. A sharp tool makes a huge difference. Always keep your tools sharp and well-aligned! Here’s a handy comparison:

| Material | Common Issues | Solutions |

|---|---|---|

| Metal | Chatter, tool wear | Adjust speed, sharpen tools |

| Wood | Snagging, tearing | Reduce feed rate, use sharp tools |

So, whether you’re spinning metal or wood, remember that a little tweak can turn a disaster into a masterpiece!

Conclusion

In summary, a lathe parting tool is essential for shaping materials. Metal lathes are great for hard metals, while wood lathes excel at crafting wood projects. Understanding these differences helps you choose the right tool for your needs. Explore more about lathes and try using one in your next project. Happy crafting!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Parting Tools For Metal Lathes Versus Wood Lathes:Lathe parting tools are used to cut materials on lathes, but they work differently for metal and wood. For metal lathes, the tools are usually stronger and sharper. This helps cut through hard materials. Wood lathes use tools that are designed to cut softer wood safely. Both types help you create different shapes and designs, but the tools fit their specific material.

Sure! Please let me know what question you’d like me to answer.

What Are The Main Differences In Design And Functionality Between Parting Tools Used On Metal Lathes And Those Used On Wood Lathes?Parting tools for metal lathes are longer and thinner. They help cut through hard metal. In contrast, wood lathe tools are often wider and thicker. They cut through softer wood. The shapes and sizes help them work better on different materials.

How Does The Material Of The Parting Tool Affect Its Performance In Metalworking Versus Woodturning?The material of a parting tool changes how well it works for metal or wood. For woodturning, we often use tools made of high-speed steel. This material is sharp but soft enough to cut through wood easily. In metalworking, we might choose carbide tools, which are much harder and can handle tough metals better. So, metal requires stronger tools because it is harder than wood.

What Are The Specific Considerations When Using A Parting Tool On A Metal Lathe Compared To A Wood Lathe?When using a parting tool on a metal lathe, you need to be careful because metal is harder than wood. You should use the right speed and pressure, or the tool can break. The cutting edge of the parting tool must be sharp so it cuts cleanly. Also, make sure to support the metal piece well, or it might wobble. In wood, you can cut faster because it’s softer, but still be cautious!

Can A Parting Tool Designed For Wood Lathes Be Effectively Used On Metal Lathes, And If So, What Adjustments Are Necessary?Yes, you can use a parting tool from a wood lathe on a metal lathe. However, you may need to make some changes. The tool may not be as strong for cutting metal, so use it carefully. You should also adjust the speed and force you apply when cutting. Make sure the tool is sharp for better results!

What Safety Precautions Should Be Taken When Using Parting Tools On Metal Lathes As Opposed To Wood Lathes?When using parting tools on metal lathes, we need to be careful. Always wear safety goggles to protect your eyes from metal shavings. Keep your hands away from the cutting area to avoid getting hurt. Make sure your work area is clean so you don’t trip or slip. Also, check the tool and machine for any damage before starting.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Parting Tools For Metal Lathes Versus Wood Lathes:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe parting tools are used to cut materials on lathes, but they work differently for metal and wood. For metal lathes, the tools are usually stronger and sharper. This helps cut through hard materials. Wood lathes use tools that are designed to cut softer wood safely. Both types help you create different shapes and designs, but the tools fit their specific material.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please let me know what question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Main Differences In Design And Functionality Between Parting Tools Used On Metal Lathes And Those Used On Wood Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Parting tools for metal lathes are longer and thinner. They help cut through hard metal. In contrast, wood lathe tools are often wider and thicker. They cut through softer wood. The shapes and sizes help them work better on different materials.”}},{“@type”: “Question”,”name”: “How Does The Material Of The Parting Tool Affect Its Performance In Metalworking Versus Woodturning?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The material of a parting tool changes how well it works for metal or wood. For woodturning, we often use tools made of high-speed steel. This material is sharp but soft enough to cut through wood easily. In metalworking, we might choose carbide tools, which are much harder and can handle tough metals better. So, metal requires stronger tools because it is harder than wood.”}},{“@type”: “Question”,”name”: “What Are The Specific Considerations When Using A Parting Tool On A Metal Lathe Compared To A Wood Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a parting tool on a metal lathe, you need to be careful because metal is harder than wood. You should use the right speed and pressure, or the tool can break. The cutting edge of the parting tool must be sharp so it cuts cleanly. Also, make sure to support the metal piece well, or it might wobble. In wood, you can cut faster because it’s softer, but still be cautious!”}},{“@type”: “Question”,”name”: “Can A Parting Tool Designed For Wood Lathes Be Effectively Used On Metal Lathes, And If So, What Adjustments Are Necessary?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, you can use a parting tool from a wood lathe on a metal lathe. However, you may need to make some changes. The tool may not be as strong for cutting metal, so use it carefully. You should also adjust the speed and force you apply when cutting. Make sure the tool is sharp for better results!”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Using Parting Tools On Metal Lathes As Opposed To Wood Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using parting tools on metal lathes, we need to be careful. Always wear safety goggles to protect your eyes from metal shavings. Keep your hands away from the cutting area to avoid getting hurt. Make sure your work area is clean so you don’t trip or slip. Also, check the tool and machine for any damage before starting.”}}]}