Have you ever wondered what makes a great metal lathe? Choosing the best metal lathe isn’t just about look or price. It’s all about power requirements too.

Imagine crafting a beautiful piece of metal with ease. Every lathe runs on power, but not all power is the same. You may think bigger is better, but that isn’t always true. The right balance of power can change your project.

Did you know that the best metal lathes can handle a variety of jobs? They can cut, shape, and design with precision. However, without enough power, they can struggle. This creates frustration when you want smooth results.

In this article, we will explore lathe power requirements. We will also look at some of the best metal lathe options available today. Get ready to discover what makes each lathe special! You might find the perfect tool for your next project.

Lathe Power Requirements: Best Metal Lathe Insights

Lathe Power Requirements: Best Metal Lathe Insights

Choosing the best metal lathe involves understanding power requirements. A lathe needs enough power to handle the job. Did you know that a lathe’s power often determines its capability? Lathes with higher horsepower can cut tougher materials more easily. It’s crucial to match power with your project needs. Think about what you will create. Will it be intricate designs or heavy-duty parts? The right choice makes all the difference!Factors Influencing Lathe Power Requirements

Explanation of material type and its impact on power needs. Importance of the size and complexity of workpieces.Choosing the right lathe power isn’t a walk in the park. First, the material type matters big time. Softer metals need less power, while hard metals are like gym lovers—demanding more strength! Next, consider the size and complexity of your workpiece. Bigger and trickier jobs require a beefier lathe to handle the task. Think of it as choosing a spoon for soup; a tiny spoon won’t cut it for a giant bowl!

| Material Type | Power Requirement |

|---|---|

| Softer Metals | Low |

| Hard Metals | High |

Calculating Power Requirements

Stepbystep guide on how to calculate horsepower requirements. Considerations for overloading and efficiency in power management.To find the horsepower needed for your lathe, follow these simple steps. First, measure the material you want to cut. Then, multiply the material hardness by the desired cutting speed. Next, consider the overloading. If you push too hard, you could break something or create an awkward mess. Always account for efficiency too; machines love to run smoothly. Here’s a fun fact: machines don’t drink coffee, so keep them happy with proper settings!

| Step | Action |

|---|---|

| 1 | Measure material. |

| 2 | Multiply material hardness by cutting speed. |

| 3 | Consider overloading and efficiency. |

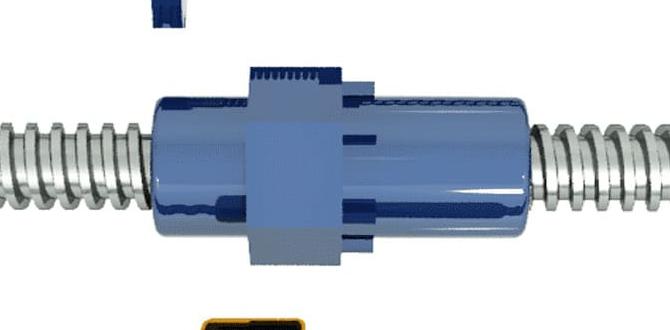

Selecting the Right Motor for Your Lathe

Types of motors used in metal lathes. How motor specifications affect performance and power consumption.Choosing the right motor for your metal lathe is vital for smooth operation. There are mainly three types of motors used:

- Brushed DC Motors

- Brushless DC Motors

- AC Induction Motors

Motor specifications impact how well your lathe performs. For instance, horsepower measures power, while RPM affects speed. Higher RPM means faster turning, but it may use more energy. Matching motor specs to your task ensures efficiency and effectiveness.

What motor types are best for metal lathes?

Brushed DC motors are great for low-speed tasks. Brushless motors offer high efficiency and longer life, while AC induction motors are good for varied speeds.

Common Power Issues and Troubleshooting

Identifying signs of inadequate power supply. Solutions for optimizing power usage in metal lathes.Power problems can slow down a metal lathe. Recognizing signs of an inadequate power supply is crucial. Watch for these signs:

- Frequent machine stops.

- Unusual noises from the motor.

- Dim machine lights.

To boost power use, consider these solutions:

- Ensure proper wiring.

- Use dedicated circuits.

- Regularly check connections.

Optimizing power can lead to smooth operations and better results.

How to identify power issues?

Look for unusual sounds, machine stops, or flickering lights. These signs may indicate power problems.

What can help save power in metal lathes?

Make sure your lathe is on its own circuit to improve power efficiency and keep the machine running well.

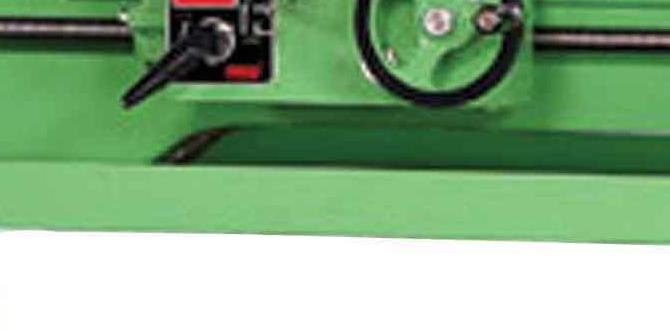

Recommendations for the Best Metal Lathes

Top models and their power specifications. Features to look for when assessing lathe power requirements.Looking for the best metal lathes? Here are top models that fit your needs. Consider their power specifications. A good lathe should have sufficient torque and horsepower to handle tough materials. Here’s what to check:

- Motor power: Higher horsepower means better performance.

- Variable speed settings: This allows flexibility for different projects.

- Durability: Strong build ensures longevity.

- Size: Compact models are great for smaller spaces.

What are essential features for a metal lathe?

When you look for lathes, pay attention to these features. High-quality lathes are designed for safety and ease of use. Look for user-friendly controls and good customer support when choosing your machine. Always check for positive reviews from other users before buying.

Conclusion

In summary, choosing the best metal lathe means considering its power requirements. Higher horsepower helps with tough materials. Look for features that match your projects. Always check reviews and compare models. If you’re serious about metalworking, invest time in research. Explore more resources online to fully understand your options. Happy lathe shopping!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Power Requirements And The Best Metal Lathe:To choose the best metal lathe, think about what you need it for. A good lathe should have enough power to cut the metal you want. Look for one that is easy to use and fits your space. You may want to check reviews to see what other people like. Always remember to stay safe while using machines!

Sure! Please give me the question you’d like me to answer, and I’ll help you out.

What Are The Key Factors To Consider When Determining The Power Requirements For A Metal Lathe?When figuring out how much power a metal lathe needs, think about a few important things. First, consider the size of the metal you will be working with. Bigger metals need more power. Next, look at the type of work you plan to do. Some jobs are harder and require a stronger motor. Lastly, check the lathe’s speed settings. Higher speeds can also change how much power you need.

How Does Motor Size And Type Influence The Performance Of A Metal Lathe?The motor size and type can change how a metal lathe works. A bigger motor usually gives more power. This means it can cut through metal faster and easier. If the motor is strong, we can use it for tougher jobs. A good motor helps the lathe work smoothly and last longer.

What Are The Recommended Horsepower Ratings For Hobbyist Versus Industrial Metal Lathes?For a hobbyist metal lathe, you usually need about 1 to 2 horsepower (HP). This is enough for fun projects at home. For industrial lathes, you might need 5 to 10 HP or more. These machines work on bigger jobs and need more power. Always pick the right power for your projects!

How Do The Power Requirements Of Cnc Lathes Compare To Traditional Manual Lathes?CNC lathes, which stands for Computer Numerically Controlled lathes, usually need more power than manual lathes. This is because CNC lathes have motors and computers that help them work quickly and precisely. Manual lathes use mostly your strength, so they need less power. Even though CNC lathes use more electricity, they can make complicated shapes faster and easier.

What Specifications Should I Look For In A Metal Lathe To Ensure It Meets My Project’S Power Demands?You should check the horsepower of the metal lathe. Higher horsepower means it can handle tougher jobs. Look for a lathe with variable speed. This lets you control how fast it spins. Also, check the size of the motor. A bigger motor can do more work without getting tired.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Power Requirements And The Best Metal Lathe:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To choose the best metal lathe, think about what you need it for. A good lathe should have enough power to cut the metal you want. Look for one that is easy to use and fits your space. You may want to check reviews to see what other people like. Always remember to stay safe while using machines!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please give me the question you’d like me to answer, and I’ll help you out.”}},{“@type”: “Question”,”name”: “What Are The Key Factors To Consider When Determining The Power Requirements For A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When figuring out how much power a metal lathe needs, think about a few important things. First, consider the size of the metal you will be working with. Bigger metals need more power. Next, look at the type of work you plan to do. Some jobs are harder and require a stronger motor. Lastly, check the lathe’s speed settings. Higher speeds can also change how much power you need.”}},{“@type”: “Question”,”name”: “How Does Motor Size And Type Influence The Performance Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The motor size and type can change how a metal lathe works. A bigger motor usually gives more power. This means it can cut through metal faster and easier. If the motor is strong, we can use it for tougher jobs. A good motor helps the lathe work smoothly and last longer.”}},{“@type”: “Question”,”name”: “What Are The Recommended Horsepower Ratings For Hobbyist Versus Industrial Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For a hobbyist metal lathe, you usually need about 1 to 2 horsepower (HP). This is enough for fun projects at home. For industrial lathes, you might need 5 to 10 HP or more. These machines work on bigger jobs and need more power. Always pick the right power for your projects!”}},{“@type”: “Question”,”name”: “How Do The Power Requirements Of Cnc Lathes Compare To Traditional Manual Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “CNC lathes, which stands for Computer Numerically Controlled lathes, usually need more power than manual lathes. This is because CNC lathes have motors and computers that help them work quickly and precisely. Manual lathes use mostly your strength, so they need less power. Even though CNC lathes use more electricity, they can make complicated shapes faster and easier.”}},{“@type”: “Question”,”name”: “What Specifications Should I Look For In A Metal Lathe To Ensure It Meets My Project’S Power Demands?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should check the horsepower of the metal lathe. Higher horsepower means it can handle tougher jobs. Look for a lathe with variable speed. This lets you control how fast it spins. Also, check the size of the motor. A bigger motor can do more work without getting tired.”}}]}