Have you ever wondered how a metal lathe works? It might seem like a big machine that just spins. But there’s more to it! The lathe needs power to function properly. And understanding lathe power requirements is key to ensuring it runs smoothly.

Many people don’t realize how crucial lathe accessories are. These tools make metalworking easier and more precise. Imagine trying to carve a beautiful shape without the right tools. It wouldn’t turn out great, would it?

Did you know that using the wrong power supply can damage your lathe? It’s important to match your machine with the right power level. This helps you get the best performance possible. Plus, having the right accessories can open up a world of creativity.

In this article, we will explore lathe power requirements and the best metal lathe accessories. Get ready to discover tips that can help you become a master in shaping metal!

Lathe Power Requirements: Essential Metal Lathe Accessories

Lathe Power Requirements and Metal Lathe Accessories

Understanding lathe power requirements is crucial for any metalworking project. A metal lathe needs the right amount of electricity to function effectively. But did you know that choosing the right accessories can make a big difference? Accessories like tool holders and chucks enhance your lathe’s performance. They help you achieve better precision and efficiency in your work. Imagine making cuts that are smoother than ever before! Properly powered and equipped, your lathe can turn ideas into reality.Understanding Lathe Power Requirements

Explanation of power requirements for various types of lathes. Factors affecting power needs (material type, cutting speed, etc.).Each lathe needs different power based on its type and what it cuts. Common factors include material type and cutting speed. Hard materials require more power than soft ones. Faster cutting needs extra energy too. Here’s a quick look at what affects these power needs:

- Material Type: Harder materials need more power.

- Cutting Speed: Higher speeds mean higher power requirements.

- Lathe Size: Larger lathes generally require more power.

What are the power needs for different lathes?

The power needed can vary. For small lathes, 1 to 2 horsepower is common. Bigger lathes might use 5 to 10 horsepower. Understanding these needs helps in choosing the right lathe!

Calculating Power Needs for Different Projects

Stepbystep guide to calculating power requirements for specific tasks. Examples of power needs based on material and tooling.Understanding how much power you need for your project can be like trying to solve a puzzle. First, look at the material you’re using. For soft metals, like aluminum, less power is needed. But for tougher materials, like steel, you’ll need a lot more oomph! Next, think about the tools you are using. Larger tools require more power.

| Material | Tool Type | Power Needed (HP) |

|---|---|---|

| Aluminum | Standard Tool | 1-2 |

| Steel | Heavy-Duty Tool | 3-5 |

So, remember, you shouldn’t try to cut steel with a butter knife! Always match your tools to your materials for a smooth ride.

Essential Accessories for Optimizing Lathe Performance

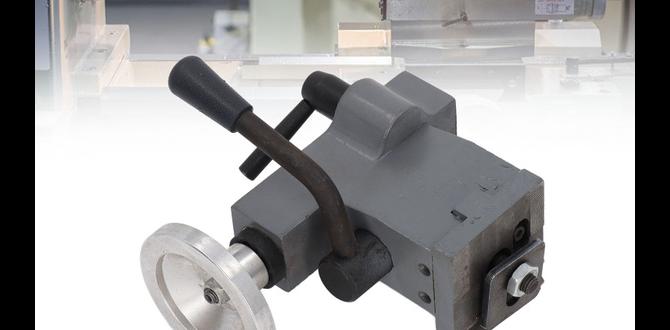

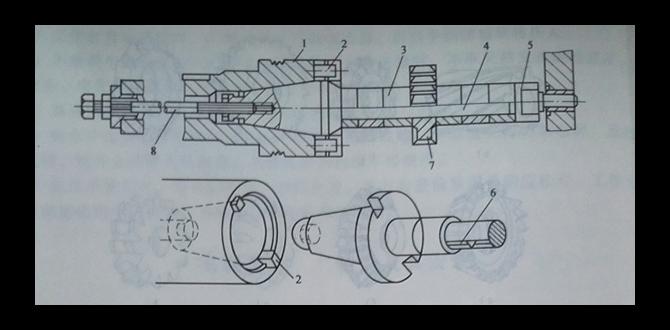

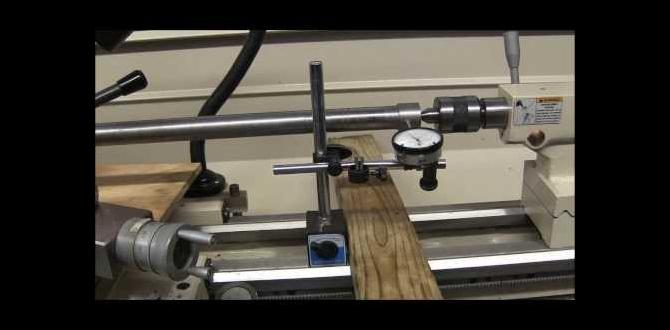

List of musthave accessories for enhancing lathe capabilities. Benefits of using the right tools and attachments.To boost your lathe’s performance, it’s essential to have the right accessories! Some must-have items include tool holders, tailstocks, and chucks. These tools help create better cuts and save time. Using the right attachments not only makes your projects easier but also keeps your lathe happy. And remember, a happy lathe means fewer muscled frowns while you work!

| Accessory | Benefit |

|---|---|

| Tool Holder | Improves precision |

| Tailstock | Supports long workpieces |

| Chuck | Securely holds materials |

By using the right attachments, you’ll notice a world of difference. It’s like giving your lathe a superhero cape!

Safety Considerations and Power Management

Safety equipment and practices for operating lathes. How to manage power supply and avoid electrical issues.Using a lathe safely is no laughing matter, but who says we can’t have fun? Always wear safety goggles to protect your eyes, and earplugs can help with the noise—a loud lathe can sound like a rock concert! Proper clothing is essential too; avoid loose clothes that can get caught.

When it comes to power management, make sure your cords are in good shape. Nobody wants a surprise shock during a turning operation! Check your power supply to avoid flickering lights that might suggest a problem. Always unplug your lathe when you’re not using it. Safety first, then we can make some cool metal shapes!

| Safety Equipment | Purpose |

|---|---|

| Goggles | Protects eyes from debris |

| Earmuffs | Reduces noise exposure |

| Gloves | Protects hands but use caution |

| Closed-toed shoes | Protects feet from heavy items |

Maintenance Tips for Lathe Power Systems

Routine maintenance tips to ensure optimal power delivery. Signs of power system problems and how to address them.Keeping your lathe power systems happy is like caring for a pet: they need attention and love! Regular checks on cables and connections can help ensure optimal power delivery. Look out for signs like unusual noises, flickering lights, or unexpected shutdowns. These hints mean it’s time for a little TLC. Think of these issues as your lathe saying, “Hey, I’m not feeling great!” Address them quickly to keep your machine purring smoothly!

| Signs of Power Problems | Actions to Take |

|---|---|

| Unusual noises | Inspect the power supply |

| Flickering lights | Check for loose connections |

| Unexpected shutdowns | Review overload settings |

Future Trends in Lathe Power and Accessories

Emerging technologies affecting lathe power requirements. Predictions for future developments in lathe accessories and efficiency trends.New tech is changing how lathes work. Smart controls can make them more efficient. Innovations like 3D printing and automation will improve power needs. The future looks bright for lathe accessories. Expect lightweight, durable materials that last longer. More tools will fit with different machines. This will help users work faster and smarter. Lathes might soon be able to do more tasks in one go, saving time and energy.

What are the future trends for lathe accessories?

Future trends include advanced materials and smarter designs. Accessories will likely become lighter and more adaptable. This will help users save space and improve efficiency.

Key Predictions:

- Increased automation for better efficiency.

- More compatibility with various lathe models.

- Use of smart technology for precision tasks.

Conclusion

In summary, understanding lathe power requirements helps you choose the right metal lathe. Essential accessories can improve your projects and make machining easier. Always consider your lathe’s power before adding accessories. For a successful experience, check product reviews or guides online. We encourage you to explore more about lathes and find the best tools for your needs!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Power Requirements And Metal Lathe Accessories:Lathes need power to spin and shape metal. The amount of power depends on what you’re making. Accessories help you use the lathe better, like tools for cutting or sanding. You’ll need to know how much power your lathe requires for the job. Always use the right accessories to stay safe and work well!

Sure! Please provide the question you’d like me to answer.

What Factors Should Be Considered When Determining The Power Requirements For A Metal Lathe?When figuring out the power needs for a metal lathe, you should think about a few things. First, consider the size of the projects you’ll make. Bigger projects usually need more power. Next, think about the type of metal you’ll be using; harder metals need stronger machines. Lastly, check how fast you want the lathe to go; faster speeds require more power too.

How Do Different Lathe Accessories, Such As Tool Holders And Chucks, Affect The Overall Power Consumption Of The Machine?Different lathe accessories can change how much power the machine uses. For example, tool holders can make it easier or harder for tools to cut. If the tool cuts smoothly, it uses less power. Chucks also hold the workpiece tightly, which helps the machine work better. When everything works well together, the lathe needs less energy to do its job.

What Is The Recommended Horsepower For A Metal Lathe Intended For Specific Materials Like Aluminum, Steel, Or Titanium?For a metal lathe, you want enough horsepower to cut different materials well. If you are working with aluminum, 1 to 2 horsepower is good. For steel, aim for 3 to 5 horsepower. If you are cutting titanium, you may need 5 to 10 horsepower because it’s tougher. More horsepower helps you get better results!

How Can The Proper Selection Of Lathe Accessories Enhance Machining Efficiency And Reduce Power Consumption?When you choose the right accessories for a lathe, it helps the machine work better. Good tools can cut materials faster and make smoother finishes. This means you spend less time on each job. When the lathe works easier, it uses less power too. So, choosing the right parts makes everything faster and saves energy!

What Safety Precautions Should Be Taken When Using High-Power Metal Lathes With Various Accessories?When using high-power metal lathes, you should always wear safety glasses to protect your eyes. Keep your hair tied back and remove any loose clothes or jewelry. Make sure to keep your hands away from moving parts. Always follow the machine’s instructions and ask for help if you’re unsure. Lastly, keep your workspace clean and organized to avoid accidents.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Power Requirements And Metal Lathe Accessories:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathes need power to spin and shape metal. The amount of power depends on what you’re making. Accessories help you use the lathe better, like tools for cutting or sanding. You’ll need to know how much power your lathe requires for the job. Always use the right accessories to stay safe and work well!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Factors Should Be Considered When Determining The Power Requirements For A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When figuring out the power needs for a metal lathe, you should think about a few things. First, consider the size of the projects you’ll make. Bigger projects usually need more power. Next, think about the type of metal you’ll be using; harder metals need stronger machines. Lastly, check how fast you want the lathe to go; faster speeds require more power too.”}},{“@type”: “Question”,”name”: “How Do Different Lathe Accessories, Such As Tool Holders And Chucks, Affect The Overall Power Consumption Of The Machine?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different lathe accessories can change how much power the machine uses. For example, tool holders can make it easier or harder for tools to cut. If the tool cuts smoothly, it uses less power. Chucks also hold the workpiece tightly, which helps the machine work better. When everything works well together, the lathe needs less energy to do its job.”}},{“@type”: “Question”,”name”: “What Is The Recommended Horsepower For A Metal Lathe Intended For Specific Materials Like Aluminum, Steel, Or Titanium?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For a metal lathe, you want enough horsepower to cut different materials well. If you are working with aluminum, 1 to 2 horsepower is good. For steel, aim for 3 to 5 horsepower. If you are cutting titanium, you may need 5 to 10 horsepower because it’s tougher. More horsepower helps you get better results!”}},{“@type”: “Question”,”name”: “How Can The Proper Selection Of Lathe Accessories Enhance Machining Efficiency And Reduce Power Consumption?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you choose the right accessories for a lathe, it helps the machine work better. Good tools can cut materials faster and make smoother finishes. This means you spend less time on each job. When the lathe works easier, it uses less power too. So, choosing the right parts makes everything faster and saves energy!”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Using High-Power Metal Lathes With Various Accessories?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using high-power metal lathes, you should always wear safety glasses to protect your eyes. Keep your hair tied back and remove any loose clothes or jewelry. Make sure to keep your hands away from moving parts. Always follow the machine’s instructions and ask for help if you’re unsure. Lastly, keep your workspace clean and organized to avoid accidents.”}}]}