Have you ever wondered how a metal lathe works? These machines shape metal into various parts with precision. But did you know that understanding the lathe power requirements is crucial for smooth operation?

Imagine a factory where metal lathes spin and cut, creating parts for everything from cars to toys. What makes these machines successful? It often depends on the right power supply. If the power requirements aren’t met, the lathe can struggle to function properly.

Now, let’s talk about something exciting: automation. Metal lathe automation is changing how we work. It makes the process faster and reduces human error. But remember, automation needs the right power too!

In this article, we will explore how to choose the right power for your lathe. We’ll also look at how automation can enhance your metalworking projects. Are you ready to learn more? Let’s dive into the world of lathes!

Lathe Power Requirements For Metal Lathe Automation Explained

Lathe Power Requirements for Metal Lathe Automation

Understanding the power needs of metal lathe automation is crucial for efficient performance. A metal lathe requires specific power to operate properly, which affects its speed and capabilities. Did you know that different materials might need varying power levels? Choosing the right power source can enhance productivity and reduce downtime. Plus, automating a lathe not only boosts precision but also saves time. Imagine completing complicated tasks faster—automation can make this a reality!What is a Lathe and Its Role in Metalworking?

Definition of a lathe and its basic functions.. Importance of a lathe in metalworking and manufacturing processes..A lathe is like a magic spinning chair for metal! It shapes materials into beautiful designs. Imagine holding a piece of metal while it swirls around, getting turned into parts for machines. That’s a lathe! Its main job is to cut, shape, and smooth the metal surfaces.

In metalworking, lathes are super important. They help create everything from tiny screws to giant gears. Without lathes, many of the things we use daily would be a bumpy mess!

| Function | Description |

|---|---|

| Cutting | Shapes the metal into desired profiles. |

| Smoothing | Removes rough edges for a polished finish. |

| Drilling | Makes holes in the metal for various uses. |

Power Requirements for Different Types of Lathes

Explanation of power ratings and why they matter.. Comparison of power requirements across various lathe types..Power ratings are important because they show how much energy a lathe needs to work. Different types of lathes require different power levels. For example, a small hobby lathe might need 0.5 to 1 horsepower, while larger industrial lathes can need over 10 horsepower. This difference matters for efficiency and speed. Choosing the right lathe means getting the right power for your projects.

- Hobby Lathes: 0.5 – 1 HP

- Mid-Range Lathes: 1 – 5 HP

- Industrial Lathes: 5 – 15+ HP

What are power ratings in lathes?

Power ratings show how much energy a lathe needs for its tasks. They help you identify which lathe fits your needs best.

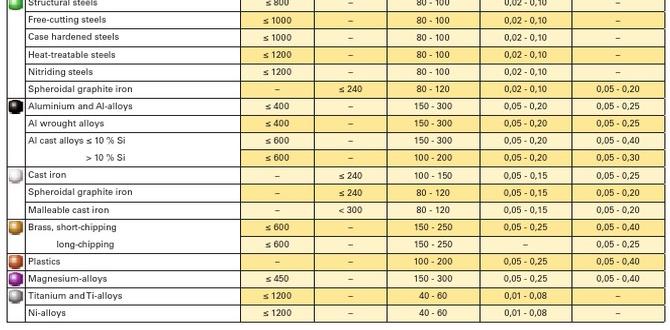

Factors Influencing Power Requirements in Lathes

Explanation of material type and size affecting power needs.. Impact of operational speed and cutting tools on power consumption..Several factors affect how much power a lathe needs. First, the material type plays a big role. Harder materials require more power. Imagine trying to cut a rock with a plastic knife—no luck! Size also matters. Bigger pieces need more muscle to shape. Next, operational speed is key. Going too fast can be wasteful, while going too slow may not cut it—literally! Lastly, the choice of cutting tools can change the energy game. A well-designed tool cuts smoothly and saves power.

| Factor | Impact on Power |

|---|---|

| Material Type | Harder materials need more power. |

| Size | Bigger items require more energy. |

| Operational Speed | Fast speeds can waste power. |

| Cutting Tools | Better tools cut efficiently. |

Calculating Suitable Power Requirements for Automated Metal Lathes

Methodology for calculating power requirements for automation.. Recommended formulas and parameters to consider..To find the right power for automated metal lathes, you need some fun math! First, consider the weight and size of the materials you’ll be working with; heavier materials need more power. Use this formula: Power (HP) = Torque (Nm) x RPM / 5252. Remember to look at the torque and speed. Don’t forget the cooling fans and lights, or your lathe might get cranky!

| Parameter | Unit |

|---|---|

| Torque | Nm |

| RPM | Revolutions per minute |

| Power | HP (Horsepower) |

So, mix the numbers wisely, check twice, and give your lathe a power boost without turning it into a superhero! Your workshop will be buzzing with happy machines in no time!

Energy Efficiency and Power Management in Automated Lathes

Strategies for optimizing energy usage in automated processes.. Importance of regular maintenance and monitoring power usage..Automated lathes can save energy and money with smart choices. Managing power well is key. Here are some simple strategies:

- Use energy-efficient tools.

- Schedule regular maintenance checks.

- Monitor power use to spot waste.

Regular maintenance keeps machines running well and cuts down on energy waste. Tracking power usage can even find hidden problems early. With better energy use, businesses can be more effective and help our planet!

Why is energy management important?

Good energy management helps lower costs and reduce waste. This keeps machines happy and saves money over time.

Case Studies of Successful Metal Lathe Automation

Examples of industries employing automated lathes effectively.. Analysis of the impact of power requirements on productivity and efficiency..Many industries have found success by using automated lathes. For example, the automotive and aerospace sectors rely on these machines for speed and precision. They can create parts faster while using less energy. This results in lower power needs and higher output. With automation, companies see a boost in productivity and quality.

- Automotive: Increases production speed by 50%.

- Aerospace: Reduces energy costs by 30%.

- Medical: Ensures high precision with fewer errors.

As a result, companies save money and deliver better products. Metal lathe automation is a game changer in these fields.

How does automation improve metal lathe performance?

Automation cuts costs and increases output, allowing manufacturers to work more efficiently.

Future Trends in Lathe Automation and Power Requirements

Insights into emerging technologies influencing lathe power needs.. Predictions for the future of metal lathe automation..New technologies are shaking up how we think about machines. For lathes, the power needs are changing fast. Smart features are helping automate tasks. This means less manual effort and quicker results. Predictions show that future lathes will require less energy while becoming super efficient. Talk about a win-win! Some experts even say automation could double production speed. Now that’s something to spin about!

| Trend | Impact on Power Requirements |

|---|---|

| Smart Automation | Less energy needed |

| Energy-efficient Motors | Lower costs and improved output |

| Data Analytics | Better performance tracking |

Conclusion

In summary, understanding lathe power requirements is crucial for effective metal lathe automation. You need the right power to ensure smooth operations. Always check your machine’s specifications. Remember, proper setup leads to better results. If you’re interested, explore more about automation techniques. This knowledge will boost your metalworking skills and help you create amazing projects. Keep learning and experimenting!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Power Requirements And Metal Lathe Automation:Sure! When you use a lathe, it needs power to work. This power helps it spin and cut metal. You can use machines to make lathes work on their own, which is called automation. This means they can do tasks without needing someone to watch all the time. It makes the work faster and easier for everyone!

Sure! Just give me the question you’d like me to answer, and I’ll keep it simple and clear for you!

What Factors Determine The Power Requirements For A Metal Lathe In Industrial Applications?The power needed for a metal lathe depends on a few key things. First, the size of the metal you are working with matters. Bigger pieces need more power. Second, the type of cuts you make can change the power needed too. Harder metals also need more energy to cut through compared to softer ones. Finally, how fast you want to work affects the power requirements, since faster speeds often need more power!

How Can Automation Technologies Improve The Efficiency Of Power Usage In Metal Lathe Operations?Automation technologies can help metal lathes use less power. When machines run on their own, they can work faster and better. We can also set them to turn off when not needed. This helps save energy. By using smart tools, we get more done while using less power!

What Are The Typical Power Ratings For Various Types Of Metal Lathes, And How Do They Vary By Application?Metal lathes usually have power ratings between 1 to 10 horsepower (HP). A small lathe for home use might have about 1 to 2 HP. Larger machines used in factories can go up to 10 HP or more. The power you need depends on what you’re making. Bigger jobs need more power, while smaller jobs need less.

How Does The Integration Of Cnc (Computer Numerical Control) Technology Impact The Power Consumption Of A Lathe?Using CNC technology makes lathes work better and faster. This means they use less power, especially when making many pieces. The computer helps control the machine, so it runs smoothly. You save energy and get good quality in your work!

What Safety Considerations Should Be Taken Into Account When Automating Lathes With High Power Requirements?When we automate lathes that use a lot of power, we need to keep safety in mind. First, we should make sure the machines are shielded so no one gets hurt. We also need to have emergency stops within easy reach. It’s important to keep tools and materials organized to avoid accidents. Lastly, we should always wear protective gear, like goggles and gloves, to stay safe while working.