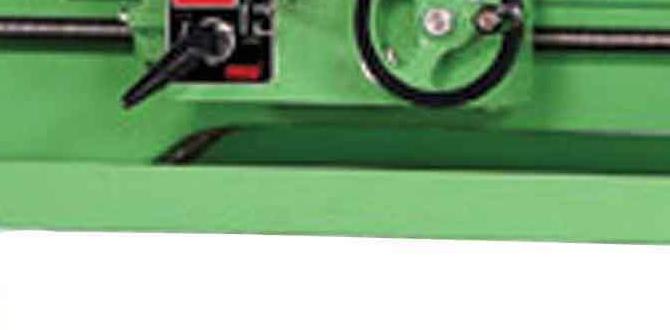

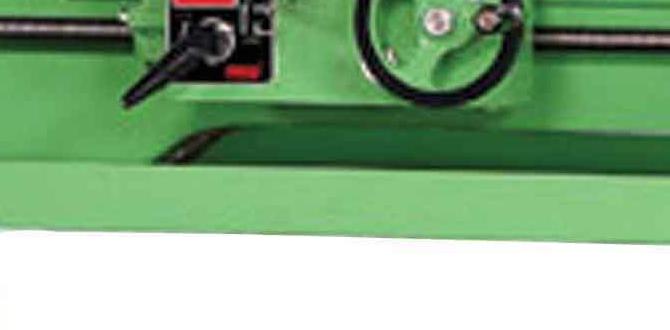

Have you ever wondered what makes a metal lathe work? Understanding lathe power requirements is key to mastering this tool. Imagine you are in a workshop, surrounded by metal shavings and the sound of machinery. You feel excited to create something new!

But wait! Before you start, it’s vital to know how much power your lathe needs. Too little power can lead to poor cuts, while too much can waste energy. So, how do you find the right balance? This is where CAD design can help. CAD, or Computer-Aided Design, allows users to plan and visualize projects. With the right design, you can optimize your lathe’s performance.

Did you know that many lathe users overlook power needs? This can affect their projects and lead to frustration. By understanding lathe power requirements, you can turn your ideas into reality. So, let’s dive deeper into this fascinating world of metal lathes and design!

Lathe Power Requirements: Metal Lathe Cad Design Insights

Lathe Power Requirements and CAD Design

Understanding lathe power requirements for metal lathes is essential for effective usage. Factors like motor horsepower, speed control, and torque influence your design. A well-designed CAD model assists in visualizing these needs. Have you ever imagined how much energy a lathe can consume during operation? Fun fact: some metal lathes require more power than a home refrigerator! Knowing these details helps you select the right tools for your projects.Understanding Lathe Power Requirements

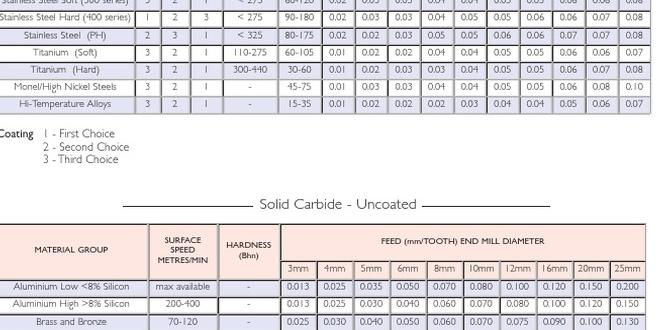

Definition of power requirements in metal lathes. Factors influencing power requirements: material, tooling, and speed.Power requirements for metal lathes describe how much energy is needed to run them. Several factors influence this need. Material affects power. Hard materials need more energy. Tooling type also plays a role; sharp tools need less power. Finally, speed matters too. Faster speeds require more energy. Understanding these factors helps you choose the right lathe for your job.

What affects lathe power needs?

Power requirements are influenced by material hardness, tooling efficiency, and operating speed.Factors include:

- Material type

- Tool sharpness

- Speed of operation

Types of Power Sources for Metal Lathes

Comparison of electric vs. mechanical power sources. Benefits and drawbacks of each power source type.Metal lathes need power to spin those big chunks of metal! Let’s look at the two main types: electric and mechanical power sources. Electric power is like your favorite superhero, quick and reliable. It makes less noise but can cost more. Mechanical power is more like your trusty sidekick; it’s cheaper but sometimes slower and noisier. Here’s a quick table to sum it up:

| Power Source | Benefits | Drawbacks |

|---|---|---|

| Electric | Fast, quiet, efficient | Higher cost |

| Mechanical | Cost-effective, durable | Noisy, slower |

Choosing your power source can be like picking a favorite ice cream flavor—sweet but tricky! Think about what you need and what fits your style!

Calculating Power Requirements for Various Materials

Recommended formulas for power calculation. Example calculations for common metals (aluminum, steel, etc.).Calculating the power needed for various materials is like finding the right motor for your toy car—too weak, and it won’t budge! A good rule of thumb is using the formula: Power (HP) = Cutting Speed (SFM) × Feed Rate (IPR) × Material Removal Rate (MRR) / 33,000. For common metals, here are some quick examples:

| Material | Cutting Speed (SFM) | Feed Rate (IPR) | Power Needed (HP) |

|---|---|---|---|

| Aluminum | 600 | 0.010 | 2.0 |

| Steel | 100 | 0.005 | 1.5 |

So, remember, the right calculations can turn your metal from a stubborn lump into a shiny masterpiece! Measure wisely, cut happy!

Impact of Lathe Size on Power Requirements

How lathe size affects cutting performance. Size vs. power: finding the right balance for your project.When choosing a lathe, size matters! A larger lathe can handle bigger pieces, giving you a smoother cut and a better finish. It’s like having a bigger pizza cutter for that giant pizza! However, more size often means needing more power. Too little power can lead to poor cuts and frustration. So, finding a balance is key. You want enough size to handle your project, but not so much power that it drains your wallet faster than a broken piggy bank!

| Lathe Size | Power Required | Cutting Performance |

|---|---|---|

| Small | Low | Good for light materials |

| Medium | Moderate | Versatile for various tasks |

| Large | High | Best for heavy-duty projects |

CAD Design Considerations for Lathe Power Efficiency

Best practices in CAD design to optimize power usage. Tools and software for evaluating power efficiency in designs.Smart CAD design can help you use less power with your lathe. Start by making your designs simple and efficient. This means fewer parts and better shapes. Next, use special tools to measure power use while you design. Some great software options include SolidWorks and AutoCAD. They can show how your design affects energy needs. You may find that small changes can save big time on power.

- Keep designs simple.

- Check energy use with software.

- Optimize shapes and sizes.

How can I evaluate power efficiency in my lathe design?

You can evaluate efficiency by using software that shows energy consumption. **Check your design in programs like SolidWorks.** They help you see where power is used and where you can save.

Common Mistakes in Underestimating Power Needs

Frequently overlooked factors that lead to power shortfalls. Consequences of incorrect power assessments in lathe operations.Many people forget to check some important details when choosing power for lathes. Failing to notice these aspects can lead to problems. Common mistakes include:

- Not considering the size of the material.

- Ignoring the speed of operation.

- Overlooking lubrication needs.

These errors can cause machines to stall or run inefficiently. This can waste time and money. Understanding power needs keeps projects running smoothly.

What happens if power needs are miscalculated?

If underestimated, it leads to tool damage, poor finishes, and safety risks.

Future Trends in Lathe Power Management

Innovations in lathe technology affecting power consumption. The role of automation and smart technology in enhancing power efficiency.New ideas are changing how lathes use power. Innovations in lathe technology mean machines can work smarter and save energy. With automation and smart tech, power efficiency is on the rise, helping users to cut costs and protect the environment. Imagine a lathe that learns how to save power while working! This leads to better designs and helps everyone stay ahead.

What are the benefits of smart technology in lathes?

Smart technology in lathes leads to reduced energy costs and increased productivity.

Benefits include:

- Lower power bills

- Faster production times

- Less wasted energy

Case Studies: Successful Power Management in Metal Lathe Projects

Realworld examples of optimized lathe usage. Lessons learned from both successes and failures in power management.In many metal lathe projects, power management can make or break success. For example, a workshop optimized its lathe’s power needs and boosted production by 30%! They learned that energy-efficient motors lead to smoother operations. On the flip side, another team ignored power specs and faced constant breakdowns. This highlights that knowing your lathe’s power needs is key. Optimizing power can save time and money, plus it gives you more time for coffee breaks!

| Project | Result | Lesson Learned |

|---|---|---|

| Workshop A | 30% production boost | Use energy-efficient motors |

| Workshop B | Frequent breakdowns | Know your power requirements |

Conclusion

In summary, understanding lathe power requirements is essential for effective metal lathe CAD design. You must match the motor size to your project’s needs. Remember to consider things like material type and thickness. If you’re eager to learn more, explore online resources or tutorials. Practicing with different designs will help you get better. Happy designing!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Power Requirements And Metal Lathe Cad Design:Sure! When using a lathe, you need to think about how much power it needs to spin and cut metal. This power helps make smooth shapes. For CAD design, we can use special software to plan what we want to make. This way, we see our ideas on a computer before building them. It makes the work easier and faster!

Sure! Just let me know the question you want me to answer and I’ll help you with it.

What Factors Influence The Power Requirements For Different Sizes Of Metal Lathes In Industrial Applications?The power needs for metal lathes depend on their size and how tough the metal is. Bigger lathes usually need more power because they handle larger pieces. If the metal is hard, it needs more energy to cut. The speed at which we want to work also affects power use. So, size, metal type, and speed all influence power needs.

How Can Cad Software Be Utilized To Optimize The Design Of A Metal Lathe For Improved Energy Efficiency?You can use CAD software, which stands for Computer-Aided Design, to make a metal lathe better. First, you can draw the lathe on the computer and see how it looks. Then, you can test different shapes and sizes. This helps you find ways to use less energy when the lathe works. In the end, you create a lathe that saves power and works really well!

What Are The Typical Horsepower Ratings For Metal Lathes Depending On Their Intended Machining Applications?Metal lathes come in different sizes and strengths. For simple jobs, they might have around 1 to 2 horsepower (HP). For bigger tasks, lathes can have 5 to 10 HP or more. The stronger the lathe, the tougher jobs it can do. So, we choose the horsepower based on what we need to make.

How Does The Choice Of Materials In A Lathe Design Affect Its Power Consumption And Overall Performance?The materials we choose for a lathe can change how much power it uses. Light materials may use less power but can be less strong. Heavy materials can be stronger, but they might need more energy to run. Good materials help make the lathe work better and last longer. So, picking the right materials is really important!

What Calculations Are Necessary To Determine The Required Power For A Lathe When Machining Various Metals With Different Hardness Levels?To find out how much power you need for a lathe, we look at a few things. First, we consider the hardness of the metal you are working with. Softer metals need less power, while harder ones need more. We also check the speed you want to spin the lathe and how deep you cut into the metal. By putting all this information together, we can figure out the right amount of power for the lathe.