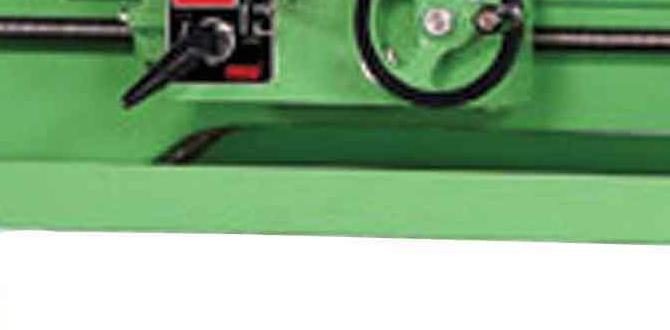

Have you ever wondered how a metal lathe works? It’s truly fascinating! A lathe can shape metal into useful parts. But, it needs power to run properly. This brings us to an important topic: lathe power requirements.

Imagine needing to create a perfect round part. The metal lathe chuck holds the metal piece tightly. Yet, if your lathe doesn’t have enough power, it struggles to get the job done. This can lead to mistakes or poor quality. Who wants that?

Here’s a fun fact: not all lathes are the same. Depending on the type and size, different machines have different power needs. Learning about these requirements can make your projects easier and more successful.

In this article, we’ll explore how to match your lathe’s power with its chuck. Ready to dive deeper? Let’s get started!

Lathe Power Requirements For Metal Lathe Chuck Selection

Lathe Power Requirements for Metal Lathe Chucks

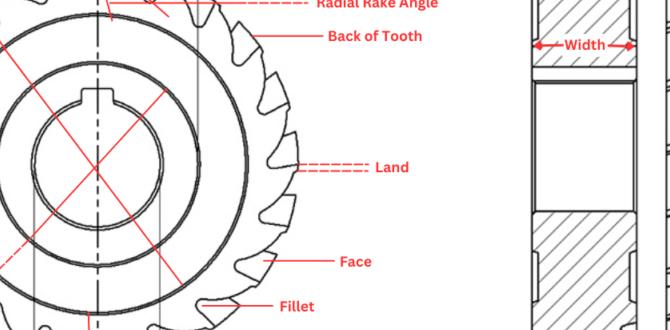

Understanding lathe power requirements is crucial for metalworking. A metal lathe chuck holds materials in place while they spin. The power needed depends on the size and type of operation. Choosing the right motor ensures efficiency and safety. Have you ever wondered how much power is really needed to create perfect cuts? Surprisingly, even small lathes need sufficient torque to handle tough metals. Make sure to match your lathe’s power with its workload for the best results.Basics of Lathe Machines

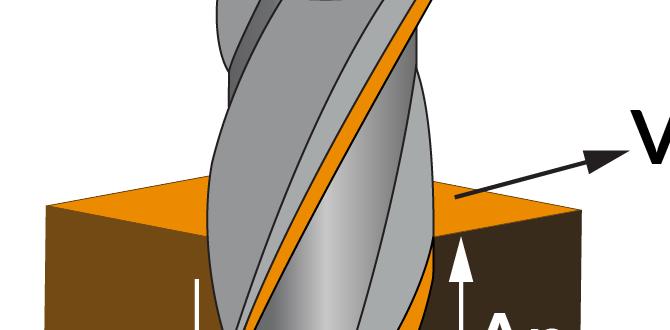

Definition and function of a lathe machine. Different types of lathe machines and their applications.A lathe machine is a tool that shapes materials like wood or metal. It spins the material and uses cutting tools to create smooth surfaces or special shapes. There are different types of lathes, and each serves a unique purpose:

- Engine Lathe: Common in workshops for cutting various materials.

- Turret Lathe: Used for making repeated designs quickly.

- CNC Lathe: A computer-controlled lathe for precise shaping.

- Wood Lathe: Specifically for turning wood items.

Each type has its own strengths and is essential for different jobs in industries like manufacturing and carpentry.

What is the main function of a lathe machine?

The main function of a lathe machine is to shape materials. It holds the material in place and spins it while a tool cuts away unwanted parts. This makes it easy to create beautiful shapes and smooth surfaces.

Understanding Power Requirements

Explanation of power ratings for lathes. Factors influencing power requirements in lathe operations.Power ratings show how strong a lathe is for work. These values help users choose machines for their projects. Factors that influence power needs include:

- Size of the material

- Type of cut required

- Speed and feed rates

Understanding these elements ensures you pick the right lathe. This can make your work easier and more efficient.

What is power rating for lathes?

The power rating for lathes indicates their strength. A higher rating means a stronger machine. It helps in choosing the right lathe for heavy tasks.

What affects power requirements in lathe operations?

The factors affecting power requirements include the size and hardness of materials, the desired cut type, and the chosen speed. Each of these can change the amount of power needed for efficient cutting.

Calculating Power Requirements for Metal Lathes

Formulas to determine power requirements. Examples of calculations based on different lathe tasks.Power requirements for metal lathes can sound complicated, but they are manageable with the right formulas. To calculate power, use the formula: Power (HP) = (Diameter × Length × RPM) / 12. This helps you understand how much power your lathe needs based on what you’re doing. For example, turning a bigger piece means more power! Take a look at this handy table:

| Task | Power Required (HP) |

|---|---|

| Turning a small part | 1-2 |

| Turning a medium part | 2-4 |

| Turning a large part | 5-10 |

Using this, you can choose the right lathe for your job! Remember, no one wants a lathe that runs out of juice halfway through a project— that’s like a car running out of gas on a trip to Disneyland!

Factors Affecting Chuck Performance and Power Usage

Material types and their impact on power requirements. Speed and feed rates in relation to power consumption.Various factors impact how a lathe chuck performs and its power usage. First, the type of material can make a big difference. Harder materials require more power to cut. It’s like trying to cut up a really tough steak with a butter knife—it just won’t work! Next, speed and feed rates also affect energy consumption. Higher speeds and feeds generally use more power. So, knowing the right balance is key to saving energy and keeping your tools happy!

| Material Type | Power Requirement |

|---|---|

| Soft metals | Low |

| Steel | Medium |

| Hard materials | High |

Optimizing both speed and feed rates can lead to more efficient power use, like finding the perfect gear in a race car. Remember, the trick is to find what works best for each job!

Optimizing Power Efficiency in Lathe Operations

Techniques for reducing power consumption. Best practices for efficient chuck operation.Powering a lathe is like feeding a hungry giant, it needs the right fuel! To save energy, try using low-power modes during light tasks. Keep the lathe well-oiled; a happy lathe is an efficient lathe! For chuck operations, always double-check if it’s tightly secured. A wobbly chuck is like a clumsy dancer—nothing good comes of it! Here are some tips in a handy table:

| Technique | Benefit |

|---|---|

| Use low-power modes | Less energy waste |

| Regular maintenance | Better efficiency |

| Secure chuck | Improved precision |

Remember, a well-maintained lathe can reduce power use by up to 20%!

Common Mistakes in Lathe Power Management

Typical errors in calculating power needs. Consequences of underpowered or overpowered setups.Many people make mistakes while figuring out power needs for their lathe. Common errors include:

- Not considering the machine’s workload.

- Using the wrong horsepower rating on the motor.

- Ignoring the type of material being machined.

These miscalculations can cause serious problems. If a lathe is underpowered, it may not work well, leading to damaged tools. An overpowered setup can waste energy and create safety risks. Manage power wisely to keep your projects safe and smooth!

What are the most common mistakes in lathe power management?

Common mistakes in lathe power management include failing to calculate the correct horsepower or using the wrong motor size. This can lead to either underperformance or excessive energy use.

Why is power management important?

Proper power management is crucial to ensure safety and performance. Mismanagement can cause:

- Tool damage

- Increased costs

- Safety hazards

Real-World Applications and Case Studies

Examples of industries utilizing metal lathes and chucks. Case studies on power requirements in various applications.Many industries depend on metal lathes and chucks to make their products. For example, the automotive sector uses them to create parts like gears and shafts. The aerospace industry also relies on these machines. A funny thought: imagine a rocket made with a wobbly wheel! Case studies show that understanding power needs is key. A study found that precision machining requires up to 50% more power than rough cutting. Keeping power requirements in check ensures smooth operations and less downtime.

| Industry | Application | Power Requirement |

|---|---|---|

| Automotive | Gears and Shafts | Varies, up to 20 HP |

| Aerospace | Engine Components | Varies, up to 50 HP |

| Manufacturing | General Machining | Typically 10-40 HP |

Conclusion

In summary, understanding lathe power requirements for a metal lathe chuck is crucial. You’ll need the right motor size for smooth operation. Always check the manufacturer’s guidelines for specifications. Remember to consider your projects’ demands when choosing a lathe. Explore more resources to deepen your knowledge and enhance your skills. Let’s keep learning and improving together!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Power Requirements And Metal Lathe Chucks:Sure! A lathe is a machine that helps us shape metal. It needs power to work, like electricity or a motor. Metal lathe chucks hold the metal tight while we shape it. Choosing the right size of the lathe and chuck is important to get good results. Always be careful and follow safety rules when using a lathe!

Sure! Please provide the question you would like me to answer.

What Factors Influence The Power Requirements Of A Metal Lathe When Using Different Types Of Chucks?The type of chuck you use on a metal lathe can change how much power it needs. For example, a heavy chuck holds bigger pieces and demands more power to spin. A lighter chuck is easier and needs less power. The material you’re working with also matters; harder materials require more energy. So, when you choose a chuck, think about its weight and what you’re cutting!

How Does The Size And Weight Of A Chuck Affect The Overall Performance And Power Consumption Of A Lathe?The chuck is the part of a lathe that holds the piece you’re working on. A bigger, heavier chuck gives you better grip and stability. This makes it easier to cut materials smoothly. However, it can use more power because it needs stronger motors to turn it. So, you have to balance size and weight for the best results.

What Is The Recommended Horsepower For A Lathe When Working With Heavy Materials Using A Four-Jaw Chuck?When using a lathe with a four-jaw chuck for heavy materials, you usually want at least 2 to 3 horsepower (HP). This power helps the lathe cut through tough materials easily. If you can, a lathe with 5 HP is even better for really heavy work. More horsepower means better performance and less strain on the machine.

How Do Variable Speed Motors Impact The Power Requirements Of A Metal Lathe With Various Chuck Configurations?Variable speed motors let you change how fast the metal lathe spins. This helps you use the right speed for different jobs. When you change the chuck, which holds the metal, the power needed might change too. If the chuck is bigger, it might need more power. So, variable speed motors make it easier to get the right power for different tasks.

What Safety Considerations Should Be Taken Into Account Regarding Power Requirements When Using A Lathe With A Specific Chuck Type?When using a lathe, you need to make sure it has enough power to run safely. Check that the chuck type you use can handle the material you want to work on. If it’s too strong or too weak, it could break or cause accidents. Always follow the instructions and don’t overload the lathe. Safety first means keeping yourself and others safe while working!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Power Requirements And Metal Lathe Chucks:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine that helps us shape metal. It needs power to work, like electricity or a motor. Metal lathe chucks hold the metal tight while we shape it. Choosing the right size of the lathe and chuck is important to get good results. Always be careful and follow safety rules when using a lathe!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Factors Influence The Power Requirements Of A Metal Lathe When Using Different Types Of Chucks?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The type of chuck you use on a metal lathe can change how much power it needs. For example, a heavy chuck holds bigger pieces and demands more power to spin. A lighter chuck is easier and needs less power. The material you’re working with also matters; harder materials require more energy. So, when you choose a chuck, think about its weight and what you’re cutting!”}},{“@type”: “Question”,”name”: “How Does The Size And Weight Of A Chuck Affect The Overall Performance And Power Consumption Of A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The chuck is the part of a lathe that holds the piece you’re working on. A bigger, heavier chuck gives you better grip and stability. This makes it easier to cut materials smoothly. However, it can use more power because it needs stronger motors to turn it. So, you have to balance size and weight for the best results.”}},{“@type”: “Question”,”name”: “What Is The Recommended Horsepower For A Lathe When Working With Heavy Materials Using A Four-Jaw Chuck?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a lathe with a four-jaw chuck for heavy materials, you usually want at least 2 to 3 horsepower (HP). This power helps the lathe cut through tough materials easily. If you can, a lathe with 5 HP is even better for really heavy work. More horsepower means better performance and less strain on the machine.”}},{“@type”: “Question”,”name”: “How Do Variable Speed Motors Impact The Power Requirements Of A Metal Lathe With Various Chuck Configurations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Variable speed motors let you change how fast the metal lathe spins. This helps you use the right speed for different jobs. When you change the chuck, which holds the metal, the power needed might change too. If the chuck is bigger, it might need more power. So, variable speed motors make it easier to get the right power for different tasks.”}},{“@type”: “Question”,”name”: “What Safety Considerations Should Be Taken Into Account Regarding Power Requirements When Using A Lathe With A Specific Chuck Type?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a lathe, you need to make sure it has enough power to run safely. Check that the chuck type you use can handle the material you want to work on. If it’s too strong or too weak, it could break or cause accidents. Always follow the instructions and don’t overload the lathe. Safety first means keeping yourself and others safe while working!”}}]}