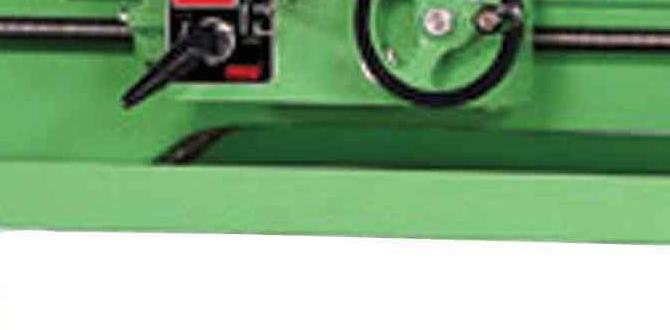

Have you ever wondered how a metal lathe works? Maybe you’ve seen one in a workshop, turning metal into beautiful shapes. But what makes these machines come to life? The answer lies in the lathe power requirements.

Upgrading your lathe to a CNC system can be exciting. It can bring your projects to the next level. But, do you know what power it needs? Understanding these power requirements is key. Without the right power, your CNC retrofit might struggle or even fail.

Here’s a surprising fact: many metal lathes use less power than you might think. Yet, they can create amazing things! Knowing how to match your lathe’s power needs with its capabilities will make your projects smoother.

Let’s dive into the world of lathe power requirements. This knowledge can help you choose the right tools for your metalworking journey. Get ready to unleash the potential of your lathe!

Lathe Power Requirements For Metal Lathe Cnc Retrofit

Lathe Power Requirements for CNC Retrofit

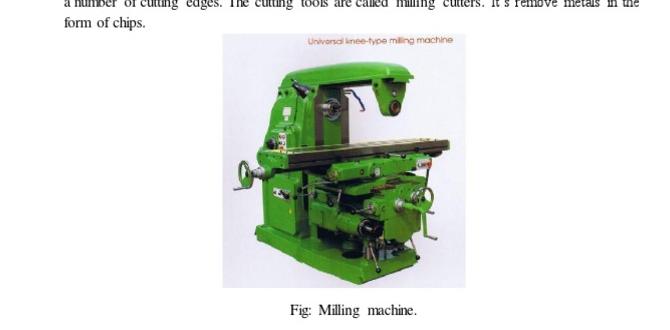

Understanding lathe power requirements is crucial for anyone considering a CNC retrofit. Old lathes often need new motors to handle increased workloads. It’s important to match the motor’s horsepower with your lathe’s size and expected tasks. Did you know that even slight mismatches can lead to performance problems? Proper power supply also ensures smoother operations and longer tool life. Investing time in these details can make your metalworking journey much easier and more efficient!What is a CNC Retrofit?

Definition and purpose of CNC retrofitting. Benefits of retrofitting a metal lathe with CNC technology.A CNC retrofit upgrades older machines with modern technology. This change helps machines work better and faster. By using CNC systems, operators can create precision parts easily. The benefits include:

- Increased accuracy: Machines make fewer mistakes.

- Higher efficiency: They can produce more parts in less time.

- Cost savings: Upgrading can be cheaper than buying new machines.

Overall, retrofitting makes it easier to meet today’s manufacturing demands.

What is the advantage of retrofitting a lathe?

The main advantage is improved performance. It allows the lathe to produce complex shapes quickly. Many businesses see a large boost in productivity after retrofitting. This change can result in greater profits over time.

Importance of Power Requirements in CNC Retrofits

Why power requirements are crucial for performance. Effects of inadequate power on CNC operations.Power is key to making CNC machines work well. Without enough power, machines struggle. This can lead to slower speeds and inaccurate cuts. When a machine doesn’t get the right energy, it behaves poorly, which can cause mistakes. These mistakes may lead to wasted materials and time.

- Poor performance

- Inaccurate operations

- Increased wear and tear

- Lower quality results

Ensuring proper power levels helps machines run smoothly and stay reliable. This way, makers can create quality products without hassle.

Why are power requirements important for CNC retrofits?

Power requirements ensure machines operate effectively and safely. They prevent errors and extend the machine’s life.

Calculating Power Requirements for Metal Lathes

Steps to determine the necessary power rating. Key factors influencing power needs (e.g., material type, cutting speeds).To find the right power for your metal lathe, start with the material you plan to work on. Harder materials need more power. Next, consider your cutting speed. Faster speeds demand extra oomph, like a car zooming down the highway. Also, don’t forget about the tools you’ll use. They can impact your power needs, too. Think of it as a dance; if you pick up the pace, you might need a stronger partner!

| Key Factors | Impact on Power |

|---|---|

| Material Type | Harder materials require more power. |

| Cutting Speed | Higher speeds need additional power. |

| Tool Type | Different tools can change your power needs. |

Electrical Supply Considerations for Metal Lathes

Understanding voltage and ampacity requirements. The significance of phase supply (single vs. threephase).Powering your metal lathe is as important as picking the right toppings for your pizza. Start with understanding voltage and ampacity requirements. If you have the wrong voltage, it’s like using a fork to eat soup—just messy! Next up is phase supply: single-phase is easier on the wallet, but three-phase gives more power, like choosing between a bicycle and a rocket! Below is a quick look at the differences:

| Phase Supply | Pros | Cons |

|---|---|---|

| Single-Phase | Affordable, Simple | Less power, Slower |

| Three-Phase | More power, Efficient | Higher cost, Complex |

Whether you go single or three-phase, ensure you have a solid plan. A well-fed lathe is a happy lathe!

Upgrading Power Supply for Enhanced Performance

Options for upgrading existing electrical systems. Common issues and troubleshooting during upgrades.Upgrading your power supply for a metal lathe can be a game-changer. First, consider your options for upgrading existing electrical systems. You might need to install a new circuit or add a larger breaker to handle increased load. Don’t worry; it’s not rocket science! Common issues include flickering lights or tripped circuits—think of them as electrical hiccups. When troubleshooting, check connections to avoid any surprises. Remember, even machines appreciate a little pampering!

| Upgrade Options | Common Issues |

|---|---|

| New Circuit Installation | Flickering Lights |

| Larger Breaker Upgrade | Tripped Circuits |

| Power Transformer Addition | Poor Connections |

Safety Considerations in Power Management

Essential safety practices when retrofitting. Protective measures against electrical hazards.Safety is crucial during retrofitting work. Without proper precautions, accidents can happen. Here are some essential practices to follow:

- Wear safety glasses to protect your eyes.

- Use gloves to avoid electrical shocks.

- Ensure the workspace is dry and well-lit.

- Disconnect power before starting any work.

- Have a fire extinguisher nearby, just in case.

Being careful can keep everyone safe. Remember, taking a few steps can prevent serious accidents!

What are key safety measures when retrofitting a lathe?

Key measures include wearing protective gear, handling tools carefully, and keeping the work area organized.

Cost Implications of CNC Retrofit Power Requirements

Breakdown of costs associated with power upgrades. Longterm financial benefits of meeting power requirements.Upgrading to CNC power can cost money upfront. However, it leads to big savings later on. Here’s a quick look at the costs involved:

- New power supply unit for CNC retrofit.

- Installation fees by professionals.

- Purchases of compatible components.

These expenses might seem high at first, but they help you save in the long run. Better efficiency and fewer breakdowns mean less money spent on repairs. Investing in upgrades also boosts your machine’s value.

What are the long-term benefits of meeting power requirements?

Upgrading power needs increases productivity and reduces energy costs. Machines run smoother and require less maintenance, which saves more money over time.

Case Studies of Successful CNC Retrofits

Examples of metal lathes that benefited from proper power management. Lessons learned from failed retrofits due to power inadequacies.Many metal lathes have soared after smart CNC retrofits. For example, a lathe in Ohio cut its cycle time by 30%! This improvement came from better power management. However, not all stories have happy endings. One shop tried to retrofit without understanding power needs and ended up with a machine that couldn’t even turn a screw—yikes! Lessons? Always check power requirements first or risk a workshop tragedy!

| Success Stories | Lesson Learned |

|---|---|

| CNC Lathe in Ohio | Understand power needs to avoid failure. |

| California Lathe Upgrade | Regular maintenance is key to success. |

Future Trends in CNC Power Requirements

Emerging technologies in CNC and their impact on power needs. Predictions for power management advancements in metal lathes.New technologies are changing how CNC machines work. These improvements affect the power needed for metal lathes. With developments in energy efficiency, future machines will need less power. This change will make CNC manufacturing cheaper. Predictive tools will help manage power better. Here are some predictions:

- Smart sensors will track power usage.

- Advanced software will optimize energy consumption.

- Battery technology will support off-grid operations.

These trends will make CNC machines more effective and exciting in the years ahead.

What are future CNC power needs?

Future CNC machines will need less energy thanks to better technology. More efficient power management will ensure smooth operations.

How will energy efficiency change CNC machines?

Energy-efficient designs and smart tools will cut down on energy costs. This makes production easier and eco-friendlier.

Conclusion

In summary, understanding lathe power requirements is crucial for a successful CNC retrofit. Make sure your machine has enough power to handle the workload. This ensures better performance and safety. If you’re interested, explore more about retrofitting your lathe or consider joining a workshop. Remember, the right setup can lead to amazing projects!FAQs

What Are The Key Factors To Consider When Determining The Power Requirements For A Cnc Retrofit Of A Metal Lathe?When you want to add CNC (Computer Numerical Control) to a metal lathe, you need to think about a few important things. First, check how much power the motor needs to run smoothly. Next, see what type of materials the lathe will work with, like metal or wood, since these can need different power levels. You also have to make sure your power supply can give enough electricity without problems. Lastly, consider how fast you want to run the lathe, because faster speeds use more power.

How Does The Choice Of Servo Motors And Drives Impact The Overall Power Consumption In A Cnc Lathe Retrofit?Choosing the right servo motors and drives is important for a CNC lathe retrofit. Good motors and drives use less power while working. If you pick energy-efficient ones, you save on electricity bills. This means your machine can run longer without using too much energy. Overall, smart choices help you make your CNC lathe work better and save money.

What Is The Recommended Minimum Horsepower For A Metal Lathe To Effectively Handle Various Materials During Cnc Operations?For a metal lathe to work well, you need at least 1 horsepower (HP). This helps the machine cut different materials easily. If you want to use tougher metals, more power is better. A lathe with around 2 to 3 HP is great for most projects. Remember, more horsepower usually means better results!

How Can One Calculate The Power Requirements Based On The Size And Weight Of The Workpiece Being Machined On A Retrofitted Lathe?To find out how much power your lathe needs, you first look at the size and weight of the workpiece. Bigger and heavier parts need more power. You can use a formula that considers these two things along with how fast you want to spin the piece. If you measure the weight and size, you can plug those numbers into the formula to get the power. This helps make sure your lathe works well without breaking.

Are There Specific Power Supply Considerations To Keep In Mind When Converting A Traditional Metal Lathe To Cnc Functionality?Yes, there are important things to think about when changing a metal lathe to CNC, which means Computer Numerical Control. First, you need to check the power needs of the new parts. This includes motors that help the lathe move. Make sure your power supply can handle these new requirements. You also want to use a power supply that works well with the CNC parts you choose.