Have you ever wondered how metal lathes work? These machines are essential in many workshops. They shape metal into various parts we use every day. But what powers them? That’s where lathe power requirements come in.

Imagine trying to carve a sculpture out of stone with just a spoon. It would be tough, right? Now think about how a lathe helps in making precise cuts. It needs the right power to function properly.

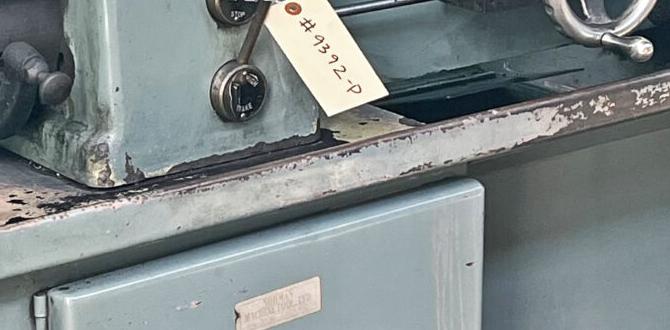

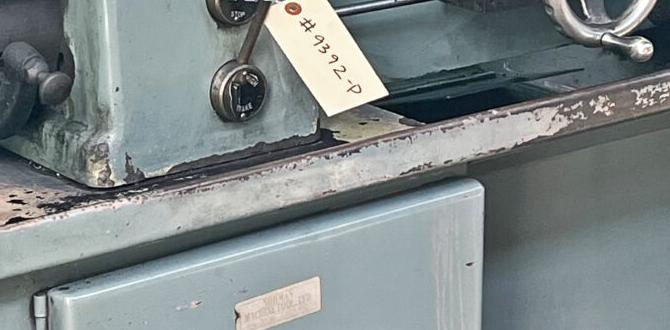

One important part of a lathe is the compound rest. It holds the tool in place while the metal spins. Understanding how to set this up correctly can make a big difference. It helps with getting accurate angles and shapes.

In this article, we will explore the power needs of metal lathes. We’ll look at how the compound rest plays a crucial role. You’ll learn why choosing the right power is key to successful metalworking. So, let’s dive into the fascinating world of lathes!

Lathe Power Requirements For Metal Lathe Compound Rest

Lathe Power Requirements for Metal Lathe Compound Rest

Choosing the right lathe power is crucial for any metal lathe project. The power needs depend on the material you’re shaping and the lathe size. A well-powered lathe can handle tough metals, ensuring smoother cuts and better finishes. Did you know that insufficient power can lead to tool wear and subpar results? Understanding these power requirements will boost your efficiency and results, making your metalworking projects more enjoyable. Ensure your lathe is up to the task before you start!What is a Metal Lathe Compound Rest?

Definition and function of the compound rest in metal lathes.. Importance of the compound rest in enhancing machining precision..A compound rest is a key part of a metal lathe. It allows the cutting tool to move in different directions. This is important for making precise cuts. With a compound rest, you can angle the tool easily. This leads to better shapes and smoother finishes.

Here are a few reasons why the compound rest matters:

- Improves accuracy: It helps in adjusting angles for exact cuts.

- Enhances versatility: You can create various shapes with ease.

- Boosts efficiency: Saves time by making setup faster.

Why is a compound rest important in metal lathes?

The compound rest is important for machine precision. It allows for detailed work that is hard to achieve without it. The more control you have, the better the results will be. Using a compound rest can lead to smoother and better-looking metal parts.

Calculating Power Requirements for a Metal Lathe

Methods to determine the necessary horsepower for specific tasks.. Sample calculations for different lathe operations and setups..Understanding how much power your metal lathe needs is crucial. It’s like choosing the right pizza size for a party—too small, and everyone goes hungry! To figure out the horsepower needed, consider what you’re doing. For tasks like turning and threading, you can use simple math based on the diameter of your workpiece and cutting speed. Equations can help, but here’s a sneak peek.

| Task | Required HP |

|---|---|

| Turning 1-inch diameter | 0.5 HP |

| Threading 0.75-inch | 0.75 HP |

This table summarizes some starter calculations. Always factor in material type, too. A softer metal might need less grunt than a hard one. Don’t worry—it’s easier than it sounds! If you keep these tips in mind, your lathe will be happy, and so will you!

Common Specifications and Ratings

Understanding RPM and its impact on power needs.. Importance of torque ratings and their relevance to performance..Understanding RPM is key for anyone operating a lathe. It tells you how fast the cutting tool spins. Higher RPM means faster work, but be careful! Too fast can lead to mistakes. Think of it like riding a bike; if you pedal too fast, you might crash! Torque ratings are also super important. They show how much force the motor can handle. Better torque means smoother performance. Imagine a strong superhero lifting heavy weights with ease—your lathe should feel just as powerful!

| Specification | Importance |

|---|---|

| RPM | Indicates speed; affects cutting efficiency |

| Torque Rating | Measures strength; ensures smooth operation |

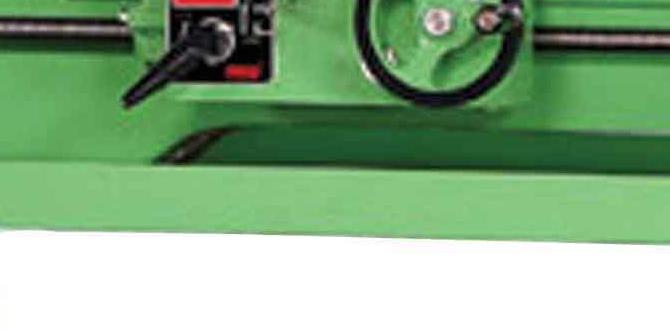

Evaluating Motor Types for Metal Lathes

Comparison of AC vs. DC motors in terms of power delivery.. Advantages and disadvantages of different motor types for lathe operations..Choosing between AC and DC motors can be tricky. AC motors are strong and good for big tasks. They run smoothly and need less maintenance. On the other hand, DC motors are perfect for precise jobs. They offer quick speed changes but might require more care. Let’s summarize their pros and cons:

- AC Motors: – Strong power delivery.

- Advantages: – Lower maintenance.

- Disadvantages: – Less precise speed control.

- DC Motors: – Fast speed adjustments.

- Advantages: – Good for detailed tasks.

- Disadvantages: – Higher maintenance needs.

Best Practices for Optimizing Power Usage

Tips for reducing energy consumption during lathe operations.. Maintenance practices to ensure efficient power usage..Saving energy during lathe operations can be both smart and fun! Start with simple habits, like turning off your machine during breaks. It can save you some serious cash and put a smile on your wallet! Regular maintenance is vital too. Keep your lathe clean and well-oiled to help it run smoothly. If your machine is grumpy, it will use more power!

| Tip | Description |

|---|---|

| Power Down | Switch off when not in use; it saves electricity! |

| Regular Maintenance | Keep it clean and oiled for smoother operation! |

| Check Settings | Use the correct speed and feed to reduce power waste. |

When equipment runs smoothly, it uses less energy. It’s like keeping your bike tires pumped up; it pedals easier! So, remember, happy lathe, happy power savings!

Potential Issues with Insufficient Power

Common problems caused by inadequate power supply to lathes.. Solutions and upgrades to address power deficiencies..When lathes don’t get enough power, problems arise. Machines can stall, leading to uneven cuts. Parts may not fit well, causing frustration. Poor performance can also harm your tools. Here are some ways to fix these issues:

- Upgrade your power supply for more reliable energy.

- Check wiring and connections to ensure everything is secure.

- Install a larger motor if you need extra strength.

These solutions help you work smoothly and achieve better results. Remember, a well-powered lathe can save time and effort!

What are common problems with insufficient lathe power?

Common problems include stalling, uneven cuts, and excessive wear on tools. These issues lead to poor quality work and safety concerns.

Future Trends in Lathe Power Efficiency

Innovations aimed at increasing power efficiency in metal lathes.. Expected advancements in technology that could affect power requirements..The world of metal lathes is buzzing with excitement! New ideas are popping up to save energy and improve efficiency. For example, engineers are creating smart lathes that adjust their power use automatically. This means they’ll use less juice when they’re not cutting metal. Isn’t that nifty? In the not-so-distant future, we might see lathes powered by renewable energy sources like solar. Who knew lathes could go green?

| Innovation | Impact on Power Efficiency |

|---|---|

| Smart Sensors | Automatically adjust power |

| Renewable Energy | Use solar or wind energy |

| Advanced Materials | Reduce energy waste |

These advancements mean lathes will work harder and smarter. Who wouldn’t want a metal lathe that saves power and acts like a superhero? Keep an eye out, because the future looks bright for power-efficient lathes!

Conclusion

In summary, understanding lathe power requirements is crucial for effective metal lathe use. The compound rest plays a key role in accuracy and versatility. To ensure safety and efficiency, always match the lathe’s power to your projects. You can explore more about lathe types and accessories to enhance your skills. Keep learning, and soon you’ll master the art of metalworking!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Power Requirements And The Compound Rest Of A Metal Lathe:Sure! A lathe is a tool that spins metal or wood to shape it. The power it needs depends on how big and strong the job is. You can think of it like how much energy you need to push a heavy box. The compound rest is a part of the lathe that helps you move the tool to make different shapes. It lets you adjust how you cut, making it easier for you to create what you want.

Sure! Please provide the question you want me to answer.

What Factors Influence The Power Requirements Of A Metal Lathe When Machining Different Materials?When you use a metal lathe to shape materials, several things affect how much power it needs. First, the type of material matters; harder metals need more power to cut. Second, the size of the pieces you’re working on can change the power needed. Lastly, the speed at which you work also plays a role; faster speeds may use more power. All these factors help determine how much energy the lathe requires to work effectively.

How Does The Design Of The Compound Rest Affect The Overall Efficiency Of A Metal Lathe?The compound rest helps us position tools on a metal lathe accurately. When the rest is well-designed, it makes it easier to change angles. This means we can cut metal shapes faster and more accurately. A good compound rest means we spend less time fixing mistakes. Overall, a better design helps us work more efficiently.

What Calculations Are Necessary To Determine The Optimal Motor Size For A Metal Lathe Based On Its Intended Applications?To find the best motor size for a metal lathe, you need to think about a few things. First, consider how heavy the materials are that you’ll be using. Next, think about the speed you need to work quickly and safely. You can also look at how thick the materials are; thicker ones need stronger motors. Finally, check the lathe’s specifications to match the motor with your projects.

How Can The Setup Of The Compound Rest Improve Accuracy And Tool Life During Machining Operations On A Metal Lathe?Setting up the compound rest correctly helps us cut metal better. It lets us adjust the angle of the cutting tool. This makes our cuts more precise, which means less waste. A good setup also reduces wear on the tool, helping it last longer. So, we get better results and save money on tools!

What Are The Typical Power Ratings For Various Sizes And Types Of Metal Lathes In Relation To Their Capability To Work With Heavy Materials?Metal lathes come in different sizes and power ratings. Small lathes usually have about 1 to 2 horsepower. Medium lathes might have 3 to 5 horsepower. Big lathes can have 10 horsepower or more, letting us work with heavy materials easily. The more power a lathe has, the thicker and heavier the metal it can handle.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Power Requirements And The Compound Rest Of A Metal Lathe:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a tool that spins metal or wood to shape it. The power it needs depends on how big and strong the job is. You can think of it like how much energy you need to push a heavy box. The compound rest is a part of the lathe that helps you move the tool to make different shapes. It lets you adjust how you cut, making it easier for you to create what you want.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Factors Influence The Power Requirements Of A Metal Lathe When Machining Different Materials?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you use a metal lathe to shape materials, several things affect how much power it needs. First, the type of material matters; harder metals need more power to cut. Second, the size of the pieces you’re working on can change the power needed. Lastly, the speed at which you work also plays a role; faster speeds may use more power. All these factors help determine how much energy the lathe requires to work effectively. “}},{“@type”: “Question”,”name”: “How Does The Design Of The Compound Rest Affect The Overall Efficiency Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The compound rest helps us position tools on a metal lathe accurately. When the rest is well-designed, it makes it easier to change angles. This means we can cut metal shapes faster and more accurately. A good compound rest means we spend less time fixing mistakes. Overall, a better design helps us work more efficiently.”}},{“@type”: “Question”,”name”: “What Calculations Are Necessary To Determine The Optimal Motor Size For A Metal Lathe Based On Its Intended Applications?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the best motor size for a metal lathe, you need to think about a few things. First, consider how heavy the materials are that you’ll be using. Next, think about the speed you need to work quickly and safely. You can also look at how thick the materials are; thicker ones need stronger motors. Finally, check the lathe’s specifications to match the motor with your projects.”}},{“@type”: “Question”,”name”: “How Can The Setup Of The Compound Rest Improve Accuracy And Tool Life During Machining Operations On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Setting up the compound rest correctly helps us cut metal better. It lets us adjust the angle of the cutting tool. This makes our cuts more precise, which means less waste. A good setup also reduces wear on the tool, helping it last longer. So, we get better results and save money on tools!”}},{“@type”: “Question”,”name”: “What Are The Typical Power Ratings For Various Sizes And Types Of Metal Lathes In Relation To Their Capability To Work With Heavy Materials?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathes come in different sizes and power ratings. Small lathes usually have about 1 to 2 horsepower. Medium lathes might have 3 to 5 horsepower. Big lathes can have 10 horsepower or more, letting us work with heavy materials easily. The more power a lathe has, the thicker and heavier the metal it can handle.”}}]}