Have you ever wondered how metal lathes work? These machines shape metal into useful parts for many industries. But there’s more to them than just spinning metal. Lathe power requirements play a big role in how well they function.

Imagine trying to carve a block of wood with a dull knife. It’s tough, right? The same goes for a lathe. Without enough power, it just can’t do its job. This is why understanding the power needs of a metal lathe is so important.

Also, many lathes come with a DRO, or Digital Readout. This nifty feature helps you measure cuts with precision. It can save time and improve accuracy. Do you think a simple upgrade can change how you use a lathe? You might be surprised!

In this article, we will explore the crucial power requirements of lathes. We’ll also dive into the benefits of adding a DRO. Get ready to learn how these tools can make your projects easier and more successful!

Understanding Lathe Power Requirements For Metal Lathe Dro

Lathe Power Requirements for Metal Lathe DRO

Choosing the right power for a metal lathe is crucial for efficiency. It affects how smoothly the machine operates. A metal lathe needs enough strength to cut various materials without stalling. Did you know that larger lathes typically require more power? Knowing the right specifications can help you avoid common pitfalls. Upgrading a Digital Readout (DRO) can enhance your lathe’s precision, making each cut more accurate and enjoyable. Understanding these elements ensures you maximize your machining experience.Defining Power Requirements for Metal Lathes

Explanation of power measurement units (horsepower, watts). How to calculate the required power based on material and operations.Power requirements for metal lathes are important for effective operations. Power is usually measured in horsepower and watts. Horsepower indicates the engine’s strength, while watts measure energy used in a second. To find the right power, consider the material and what you will do with it. Different materials need different power levels. Here’s a simple way to calculate:

- Identify the material type.

- Check the cutting speed needed.

- Use the formula: Power (HP) = Torque (ft-lbs) × RPM / 5252.

Understanding these points will help you pick the right lathe and ensure it works smoothly.

What do I need to know about horsepower and watts?

Horsepower is used for machines’ strength, while watts show how much energy is used quickly. Knowing both helps choose the best lathe.

Factors Affecting Lathe Power Requirements

Influence of workpiece material and size on power needs. Impact of cutting speed and feed rates on overall power consumption.Power needs for a lathe depend on what you’re working with. The material and size of your workpiece play big roles. Harder materials, like steel, require more power than softer ones, like aluminum. Bigger pieces often need even more horsepower, like a hungry hippo!

Next, the cutting speed and feed rates are key. Faster speeds mean a bigger appetite for power. If you feed the lathe too quickly, it might say, “Whoa, slow down!” Too much speed can lead to a mess and waste energy.

| Workpiece Material | Size | Power Requirement |

|---|---|---|

| Aluminum | Small | Low |

| Steel | Medium | Medium |

| Titanium | Large | High |

Remember, balancing these factors ensures your lathe runs smoothly and efficiently, without any power meltdowns!

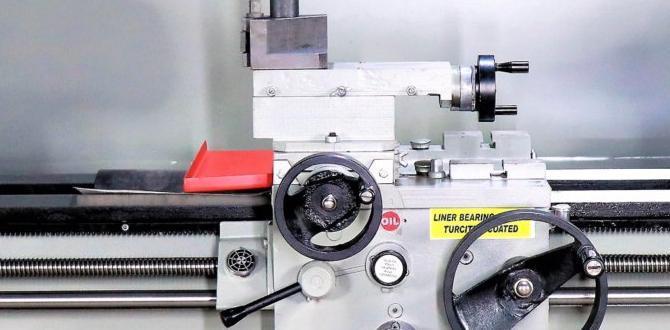

Understanding DRO Systems in Metal Lathes

Explanation of Digital Readout (DRO) systems and their importance. Impact of DRO on precision and efficiency in machining operations.Digital Readout (DRO) systems are helpful tools on metal lathes. They show exact measurements on screens. This makes work easier by helping machinists see where they are cutting. Precision is essential in machining, and DRO enhances this quality. With DRO, errors go down, and work becomes quicker. Why is this important? It means better products and less waste.

What is the impact of DRO on machining?

DRO systems improve both precision and efficiency. They allow users to make exact cuts without guessing. This leads to faster completion times. The result is higher-quality products, less scrap, and happier customers.

Key Benefits of DRO Systems:

- Increases accuracy

- Reduces errors

- Boosts machining speed

- Simplifies complex jobs

Power Supply Considerations for Metal Lathes with DRO

Requirements for electrical supply and compatibility with DRO systems. Recommendations for voltage and phase requirements for optimal performance.Choosing the right power supply for your metal lathe with a DRO is like picking a snack for a movie: you want it just right! First, make sure your electrical supply matches the lathe requirements. Most metal lathes run on either 120V or 240V, but check for compatibility with your DRO system. It’s like making sure your gummy bears don’t mix with popcorn!

For optimal performance, a three-phase system is often best. This setup provides smooth operation and less chance of a meltdown, which is good because nobody wants a hot mess (or a hot lathe!) during a project. Check the table below for a quick guide:

| Voltage | Phase |

|---|---|

| 120V | Single-Phase |

| 240V | Single-Phase or Three-Phase |

| 480V | Three-Phase |

So before you start spinning those metal masterpieces, ensure your power supply is fit for giggling, I mean, for great machining! Remember, the right voltages lead to happy lathes!

Best Practices for Managing Lathe Power Requirements

Tips for maximizing efficiency and minimizing power consumption. Maintenance strategies to ensure consistent power delivery.To manage lathe power requirements well, follow some easy tips. Begin by using low-power settings when possible. Keep your lathe clean and checked regularly for any issues. This will help it run smoothly. Also, use energy-efficient tools to cut down on power drain.

- Check the power connections.

- Use appropriate speeds for different materials.

- Regularly lubricate moving parts.

These practices keep your lathe working well and save electricity.

What are some tips for saving power with a lathe?

You can save power by using energy-efficient tools and setting your lathe to lower speeds. Regular maintenance also helps ensure optimal performance.

Common Mistakes in Estimating Lathe Power Needs

Miscalculations frequently made by users and their implications. How to avoid pitfalls in power requirement assessments.One big goof-up people make is not factoring in the material they’re working with. Hard metal needs more juice than soft stuff. Try this: always check your lathe’s horsepower against the material type. Also, don’t forget about the cutting tools! Using dull blades can overload your machine. Instead, keep tools sharp to save power and improve efficiency. To stay safe and avoid hiccups, stick to these tips:

| Common Mistakes | Implications | How to Avoid |

|---|---|---|

| Ignoring Material Hardness | Underpowered machine | Check material specs |

| Dull Cutting Tools | Increased power use | Regular tool maintenance |

By being careful, you can avoid these common pitfalls. After all, a well-informed user is a happy user! So, keep your lathe running smoothly. Remember, no one likes a cranky machine!

Future Trends in Lathe Technology and Power Efficiency

Innovations in lathe design impacting power requirements. Emerging technologies in DRO systems and their effect on lathe operations.New designs in lathe technology are changing the game. They aim for low power use while keeping machines strong and precise. These changes reduce energy costs, making operations cheaper. Digital Read-Out (DRO) systems are also improving. They give real-time data, helping operators make better decisions. As a result, lathes become more efficient. In the future, expect these trends to grow, leading to smarter and greener machining solutions.

How are innovations in lathe design affecting power use?

New lathe designs use less energy while enhancing performance. Innovations focus on lightweight materials and better motor systems, which reduce power requirements significantly.

What changes do DRO systems bring to lathe operations?

- DRO systems provide accurate measurements.

- They reduce errors and save time.

- Real-time data boosts machine efficiency.

Conclusion

In conclusion, understanding lathe power requirements is crucial for using a metal lathe effectively. A Digital Readout (DRO) offers accuracy and ease in measurements. Make sure to check your lathe’s specifications to select the right power source. For better results, explore tutorials and guides on lathe operation. With practice, you’ll improve your skills and confidence in machining!FAQs

Certainly! Here Are Five Questions Related To Lathe Power Requirements And Digital Readouts (Dro) For Metal Lathes:Sure! Here are the answers: 1. A lathe needs power to turn metal pieces. The power is measured in horsepower (HP). More HP means it can handle bigger jobs. 2. Digital readouts (DRO) show you exactly where to cut on your lathe. They make measuring easier and help you work faster. 3. When using a lathe, you should first check its power needs. This way, you won’t overload it and cause problems. 4. A good DRO can help you see numbers clearly. This keeps you from making mistakes while you work. 5. Always follow the instructions for your lathe and DRO. This will help you stay safe and work better!

Sure! Please give me the question you would like me to answer.

What Factors Should Be Considered When Determining The Power Requirements For A Metal Lathe?When deciding how much power a metal lathe needs, think about its size and what you will make. Larger lathes usually need more power. The materials you use also matter; harder materials need stronger machines. Finally, consider how fast you want the lathe to work. More speed often means more power.

How Does The Power Rating Of A Lathe Motor Impact Its Performance For Different Machining Tasks?The power rating of a lathe motor tells us how strong it is. A stronger motor can cut through harder materials easily. When you do big or tough jobs, a higher power rating helps you finish faster. If the motor is weak, it may slow down or even stop. So, the right power rating helps you get the job done better and faster.

What Is The Role Of A Digital Readout (Dro) In Improving The Accuracy And Efficiency Of Machining Operations On A Metal Lathe?A digital readout (DRO) helps us measure things on a metal lathe accurately. It shows the exact position of the cutting tool on a screen. This makes it easier for us to cut metal shapes correctly. With a DRO, we can work faster and make fewer mistakes. Overall, it helps us do better work!

How Do Varying Material Types Affect The Power Consumption And Efficiency Of A Lathe During Operation?Different materials can change how much power a lathe uses. Hard materials like steel need more energy to cut. This can make the lathe less efficient because it has to work harder. Softer materials, like plastic, use less power and are easier to shape. So, what you are working with matters for how much energy you use and how fast you finish your work.

What Are The Common Power Supply Configurations For Metal Lathes, And How Do They Influence The Machine’S Versatility?Metal lathes usually have different power supplies. Some run on electricity, while others use batteries or gas. Electric lathes are common because they are powerful and easy to control. When a lathe has a good power supply, it can work on many different projects, making it more versatile. This means you can create lots of things, like parts for machines or tools, more easily!