Have you ever watched a metal lathe in action? It’s incredible how a simple chunk of metal can become something useful. But did you know that there are specific lathe power requirements to keep everything running smoothly?

One key feature is the metal lathe foot brake. This tool is not just a safety measure; it’s essential for controlling the machine. Imagine if every time the lathe spun, you had to wait too long to stop it. That could lead to mistakes or even accidents!

In this article, we will explore how these power needs impact your work. We’ll also dive into the importance of the foot brake in ensuring safe operations. By the end, you’ll see why understanding these elements can make your metalworking projects easier and safer.

Lathe Power Requirements And Metal Lathe Foot Brake Explained Lathe Machines Are Essential Tools In Metalworking, Providing Precision And Versatility For Various Machining Processes. Understanding The Power Requirements Of A Lathe, Along With Safety Features Like The Metal Lathe Foot Brake, Is Crucial For Both Novice And Experienced Machinists. Understanding Lathe Power Requirements When Selecting A Lathe, One Of The Primary Considerations Is The Power Requirement. The Power Of A Lathe Is Typically Measured In Horsepower (Hp) And Varies Depending On The Size And Type Of Lathe. Larger Lathes Often Require More Power To Handle Heavy Workloads, Particularly When Machining Tougher Materials Like Stainless Steel Or High-Strength Alloys. A Metal Lathe Typically Needs A Power Source That Can Provide Consistent Performance Under Load. The Voltage And Phase Of The Electrical Supply (Single-Phase Vs. Three-Phase) Also Influence The Lathe’S Overall Power Requirements. Higher Quality Lathes Usually Have Better Torque Characteristics At Low Speeds, Which Is Essential For Heavy Cutting Operations. Importance Of A Metal Lathe Foot Brake Safety Is Paramount When Operating Machinery, And One Of The Critical Safety Features Of A Metal Lathe Is The Foot Brake. The Foot Brake Mechanism Allows Operators To Quickly Stop The Lathe’S Spindle And Tooling, Reducing The Risk Of Accidents Caused By Sudden Movements Or Operational Malfunctions. The Metal Lathe Foot Brake Is Designed For Easy Accessibility, Ensuring That Operators Can Engage The Brake Without Removing Their Hands From The Equipment. This Feature Is Particularly Useful During Quick Setup Changes Or When Emergencies Arise, As It Can Prevent Serious Injuries. Conclusion Understanding Lathe Power Requirements And The Importance Of Features Like The Metal Lathe Foot Brake Is Essential For Ensuring Efficient And Safe Machining Operations. Properly Assessing These Elements Can Significantly Enhance Productivity While Maintaining A Safe Working Environment. Whether You’Re A Hobbyist Or A Professional Machinist, Being Aware Of These Factors Will Contribute To Your Success In Metalworking Projects.

Lathe Power Requirements and Foot Brake Insights

Understanding lathe power requirements is crucial for safe and efficient machining. Did you know that a metal lathe often needs specific power levels to operate smoothly? The foot brake plays an essential role in controlling the machine. It allows quick stopping, enhancing safety during work. Choosing the right power source ensures the lathe performs its best. Are you ready to start your machining journey? Knowing these key points can make a big difference in your projects!Basics of Lathe Power Requirements

Explanation of power requirements for metal lathes. Factors influencing power needs (material, size, speed).Metal lathes need power to spin and cut materials. The power needed depends on three main things: the material you’re working with, the size of your workpiece, and the speed at which you operate. For example, hardwood requires less power than heavy metal. A big project will gobble up more energy than a tiny piece. Choose wisely, or your lathe might decide to take a nap instead of working hard!

| Factor | Impact on Power |

|---|---|

| Material | Hard materials need more power. |

| Size | Large pieces consume more energy. |

| Speed | Higher speeds require extra power. |

Importance of Foot Brake in Metal Lathes

Functionality and necessity of foot brakes in lathe operations. Safety advantages of incorporating a foot brake.A foot brake in metal lathes is like a superhero for your workspace. It stops the machine quickly, keeping you safe while you work. Imagine trying to make a quick adjustment, only to have the lathe keep spinning! That’s a recipe for disaster. A foot brake offers a **fast way to halt operations** and avoid accidents. Plus, it frees up your hands, allowing you to hold tools or snacks—whatever you need for your metalworking adventures!

| Functionality | Safety Advantages |

|---|---|

| Enables quick stops during operation | Reduces risk of injury |

| Helps with smooth adjustments | Allows hands-free operation |

| Improves overall efficiency | Increases operator confidence |

Calculating Power Requirements for Metal Lathes

Stepbystep guide to calculate required horsepower. Common formulas and conversions used in calculations.To find out how much horsepower your metal lathe needs, start with these simple steps. First, check the workpiece material. For example, steel needs more power than aluminum. Next, use this handy formula: Horsepower = (Torque × RPM) / 5252. Don’t worry if math isn’t your thing; it’s easier than convincing a cat to bathe! You can also convert units using an online calculator if needed. Here’s a quick table to help:

| Material | Power (HP) |

|---|---|

| Aluminum | 0.5 |

| Bronze | 0.75 |

| Steel | 1.0 |

Remember, these numbers are just a starting point. Each lathe has its quirks, like how pets have their own personalities. So, adjust your calculations based on specific lathe features!

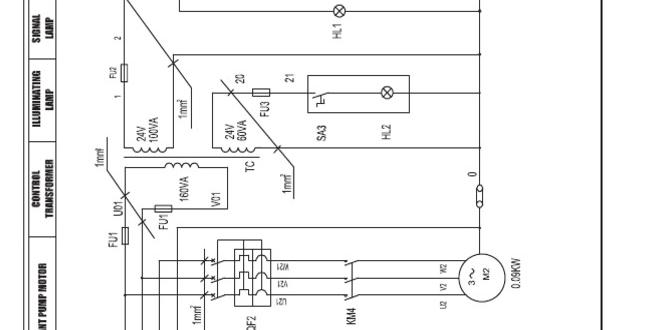

Foot Brake Mechanism and Design

Components of a typical foot brake system in metal lathes. Different designs and their effectiveness in various applications.A foot brake system is key in metal lathes, helping to stop the machine quickly. Key components include:

- **Brake Pedal**: The part you press to stop.

- **Brake Cylinder**: Pushes fluid to activate brakes.

- **Brake Pads**: Materials that grip and stop the movement.

- **Linkage**: Connects the pedal to the brakes.

Different designs offer various effectiveness. Simple systems work for light jobs, while advanced designs stop heavy machines quicker. Knowing your machine’s needs helps choose the best foot brake.

What are the key parts of a foot brake system?

The key parts are the brake pedal, brake cylinder, brake pads, and linkage.

Maintaining Optimal Power and Brake Efficiency

Tips for ensuring consistent power supply to the lathe. Maintenance best practices for foot brake to ensure longevity and safety.To keep your lathe running smoothly, focus on providing a steady power supply. Check electrical connections regularly to avoid disruptions. Keep the workspace clean to prevent dust from affecting performance. Additionally, maintaining your foot brake is essential. Here are some tips:

- Inspect brake pads for wear.

- Lubricate moving parts often.

- Ensure the brake engages smoothly.

These actions help improve efficiency and safety. Remember, a well-maintained lathe lasts longer and works better.

Why is consistent power supply important for a lathe?

Consistent power keeps the lathe operating reliably. It prevents sudden stops, ensuring smoother operations and better results. Regular check-ups enhance performance.

Common Issues with Power Supply and Foot Brake on Metal Lathes

Identification of typical powerrelated problems. Troubleshooting foot brake issues for optimal performance.Power supply and foot brake issues can trouble metal lathe users. Some common problems include:

- Power surges causing tool failure.

- Foot brake not responding properly.

- Wiring faults leading to inconsistent operation.

For foot brake issues, check connections and components. Clean the pedal and ensure no debris blocks it. Test the brake lightly to see if it engages. Address these concerns quickly for better lathe performance. Always keep your lathe in good shape to avoid bigger problems down the road.

What should I do if my metal lathe foot brake isn’t working?

Check the connections and clean the pedal area. If problems persist, consult the user manual for specific troubleshooting steps. Regular maintenance can also prevent issues.

Case Studies: Lathe Power Optimization and Foot Brake Performance

Examples of successful power management in machining environments. Analysis of foot brake performance in varied industrial settings.Many factories have found smart ways to save energy while using lathes. One factory reduced power use by 30% by scheduling heavy jobs when electricity costs are low. Another factory improved safety and performance by updating their foot brake. They observed a 25% faster stop during machining. Here are some examples of success:

- Energy savings through better scheduling.

- Updated brakes for increased safety.

How can foot brake performance improve safety?

Upgraded brakes can make machines stop faster, preventing accidents. This boosts worker safety and confidence on the job.

Conclusion

In summary, understanding lathe power requirements is vital for safe and efficient use. A metal lathe needs adequate power for smooth operation. The foot brake adds safety, allowing quick stops during work. We encourage you to check your lathe’s specifications and learn more about safe practices. By doing this, you’ll enhance your skills and confidence in using a lathe!FAQs

What Factors Influence The Power Requirements For Operating A Metal Lathe Effectively?The power needed for a metal lathe depends on a few things. First, the type of metal you are using matters. Harder metals need more power to cut them. Second, the speed at which you turn the metal affects power. Faster speeds use more power. Finally, the size of the tool cutting the metal also plays a role. Bigger tools require more energy to work well.

How Does The Size And Type Of The Metal Lathe Impact Its Power Consumption And Efficiency?The size and type of a metal lathe can change how much power it uses and how well it works. Bigger lathes often need more power to run. If a lathe is made for heavy jobs, it might use energy faster than a smaller one. Also, newer lathes with better technology can be more efficient, using less power to do the same work. So, the right size and type can help save energy and work better.

What Safety Considerations Should Be Taken Into Account When Installing A Foot Brake On A Metal Lathe?When installing a foot brake on a metal lathe, make sure to unplug the machine first. You should check that the brake is easy to reach and will stop the lathe quickly. Always wear safety glasses to protect your eyes. Keep your hands and clothes away from moving parts to avoid injury. Lastly, always test the brake before you start working.

How Can Improper Power Supply Affect The Performance And Longevity Of A Metal Lathe?If you use the wrong power supply for a metal lathe, it can cause problems. The machine might not run well, and this can lead to mistakes. Over time, these issues can wear out the lathe faster. A bad power supply might even break the machine. Taking care of the power supply helps keep the lathe working longer and better.

What Is The Recommended Power Rating For Different Applications In Metalworking When Using A Lathe?When using a lathe in metalworking, the power rating you need depends on what you’re making. For small projects, like tiny parts, 1 to 3 horsepower (HP) is enough. If you’re working on medium projects, you might need 3 to 10 HP. For big or tough jobs, you could need over 10 HP. Always choose a lathe that can handle your specific tasks!