Have you ever wondered what makes a metal lathe work? If you have, you’re not alone! Many people find themselves curious about lathe power requirements and how they impact performance. A metal lathe motor plays a key role in this. Without the right power, you can’t achieve the desired results.

Imagine trying to bake a cake without enough heat. You would end up with something very different from what you expected! The same idea applies to lathes. The power needs must match the project at hand. If the motor isn’t strong enough, it can lead to problems.

Did you know that choosing the right motor can also save you time? A well-chosen motor helps you work more efficiently. It can make a small job quicker and easier. The right lathe power requirements help ensure everything runs smoothly.

This article will explore the essentials of lathe power requirements. We’ll also discuss how to choose the right metal lathe motor for your needs. Let’s dive in and discover what makes a lathe tick!

Lathe Power Requirements: Choosing The Right Metal Lathe Motor

Lathe Power Requirements for Metal Lathe Motors

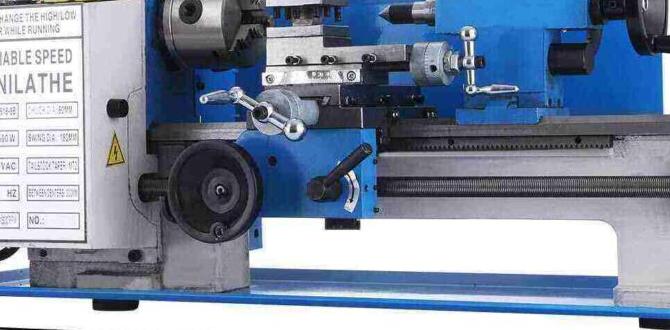

Choosing the right motor for your metal lathe is crucial. Did you know that power requirements can vary based on the lathe’s size and the materials you work with? A lathe needs enough power to spin smoothly, especially when cutting hard metals. Generally, a motor between 1 to 3 horsepower suits most needs. Understanding these power needs can make your projects faster and more efficient. After all, nobody wants a motor that can’t keep up with their creativity!Understanding Lathe Power Requirements

Definition of power requirements in metal lathes. Importance of matching motor power to lathe capacity.Power requirements refer to how much energy a metal lathe needs to run effectively. It’s like asking how many cookies you need for a snack. If your motor is too weak, it can’t handle the job. Imagine a tiny motor trying to lift a giant elephant – it just won’t work! Matching the motor’s power to the lathe’s capacity is crucial. A strong lathe with a wimpy motor is like having a superhero without superpowers.

| Lathe Capacity | Recommended Motor Power |

|---|---|

| Small (up to 10 inches) | 1 HP |

| Medium (10-15 inches) | 2 HP |

| Large (over 15 inches) | 3 HP or more |

Factors Affecting Motor Selection

Analysis of lathe size and workload. Consideration of material types being machined.Choosing the right motor for your lathe depends on several important factors. First, analyze the size of your lathe and the workload you expect it to handle. Larger lathes usually need stronger motors. Next, think about the types of materials you’ll machine. Different materials require different power. Soft metals need less power than hard materials like steel. Here are key points to consider:

- Lathe Size: Bigger lathes need stronger motors.

- Workload: Heavier tasks mean more power.

- Material Types: Softer metals need less power.

What should I consider when selecting a lathe motor?

Consider motor power based on your lathe’s size and workload. The type of material also matters. It affects how much power you’ll need. Choosing the right motor boosts your lathe’s efficiency.

Calculating Power Needs for Metal Lathes

Formula for determining horsepower requirements. Examples of calculations based on lathe dimensions and tasks.To find out how much horsepower you need for a metal lathe, you can use a simple formula. First, multiply the lathe’s diameter by its length and the material’s hardness. Then, divide the result by 33,000. Voila! You have your horsepower! For instance, a lathe with a diameter of 12 inches and a length of 36 inches will need about 1.5 horsepower for average tasks. If the job gets trickier, give it a boost!

| Lathe Diameter (inches) | Lathe Length (inches) | Horsepower Required |

|---|---|---|

| 12 | 36 | 1.5 |

| 10 | 24 | 1.0 |

| 16 | 48 | 2.0 |

This table shows different combinations of lathe sizes and the horsepower needed for various tasks. Remember, more horsepower can make your machine hum like a happy bee instead of groaning like a tired cow!

Common Motor Sizes and Ratings

Typical horsepower ratings for hobby vs. industrial lathes. Understanding RPM and its significance in motor selection.Different motors power lathes, and they come in various sizes and ratings. Hobby lathes usually have horsepower ranging from 1/2 to 2 HP. In contrast, industrial lathes might go up to 10 HP or more. Now, let’s chat about RPM, which stands for “Revolutions Per Minute.” It tells us how fast the motor spins. Higher RPM means faster cutting but can be risky if you’re not careful.

| Lathe Type | Typical Horsepower |

|---|---|

| Hobby Lathe | 1/2 – 2 HP |

| Industrial Lathe | 2 – 10+ HP |

So, whether you’re shaping a tiny toy or a hefty piece of metal, knowing your motor size and RPM is like knowing the secret ingredients in Grandma’s cookies. They make all the difference!

Energy Efficiency and Performance

Importance of energy efficiency in motor selection. Impact of motor performance on production cost.Choosing a motor that runs on less energy is like picking a bicycle with a comfy seat. It makes everything smoother! An efficient motor not only saves power but also cuts costs. Less energy used means lower bills. When motors perform well, production speeds up, and that makes your wallet happier too. So, when you’re selecting a metal lathe motor, remember: a good choice today means more savings tomorrow!

| Motor Type | Energy Efficiency | Impact on Costs |

|---|---|---|

| High Efficiency | Great | Low Production Costs |

| Standard | Good | Moderate Production Costs |

| Low Efficiency | Poor | High Production Costs |

Installation and Compatibility Issues

Key considerations for motor installation on existing lathes. Ensuring electrical compatibility and safety standards.Getting the right motor for your lathe can feel like finding a needle in a haystack. It’s important to consider how to install it properly. Check if your lathe fits the new motor snugly, like a glove on a hand. You’ll also want to ensure that the electrical connections are safe and follow the right standards. A mismatched motor could lead to sparks flying—literally! You don’t want your workshop looking like a disco party.

| Key Consideration | Description |

|---|---|

| Motor Size | Make sure the motor fits your lathe’s frame. |

| Voltage Requirements | Check that the motor matches your electrical supply. |

| Safety Standards | Follow local regulations to keep things safe. |

With these factors in mind, your lathe will run smoother than a squirrel on roller skates!

Maintenance Tips for Lathe Motors

Routine maintenance practices to extend motor lifespan. Signs of motor wear and when to consider replacements.It’s important to take good care of your lathe motor to keep it running smoothly. Regular cleaning is key—dust and grime can hide in all the little nooks and crannies. Check for any unusual sounds or smells; they might be your motor’s way of saying, “Help me!” If you notice a drop in power, it might be time to evaluate your motor. Here’s a simple table to remember the signs of wear:

| Signs of Wear | Action to Take |

|---|---|

| Strange noises | Inspect for loose parts |

| Burning smell | Stop and cool down immediately |

| Power drops | Consider replacement |

Keeping an eye on these signs can save you from a motor meltdown. Remember, a happy motor means happy lathe work!

Conclusion

In summary, understanding lathe power requirements is crucial for choosing the right motor. You need enough horsepower to handle your projects. A suitable motor ensures smooth operation and better results. We encourage you to research different motor options for your metal lathe. This knowledge will help you make informed choices for your future projects. Happy turning!FAQs

What Factors Should Be Considered When Determining The Power Requirements For A Metal Lathe Motor?When figuring out how powerful a metal lathe motor needs to be, we consider a few things. First, think about the size of the metal pieces you will use. Bigger pieces usually need more power. Next, look at how fast you want to turn the metal. Faster speeds also need more power. Finally, consider the type of metal. Harder metals require stronger motors to work well.

How Does The Size And Type Of Material Being Machined Affect The Motor Power Needed For A Lathe?The size and type of material you are working with on a lathe changes how much power the motor needs. If you are cutting a big piece of metal, it needs more power than a small piece of wood. Hard materials also need more motor power because they are tougher to cut. So, the bigger and harder the material, the stronger the motor has to be!

What Are The Common Horsepower Ratings Found In Metal Lathe Motors, And How Do They Correspond To Different Lathe Applications?Metal lathe motors usually have horsepower (HP) ratings between 1/2 HP and 3 HP. If you have a small lathe, like for home use, 1/2 HP is often enough. For medium tasks, around 1 HP works well. Larger metalworking jobs might need 2 HP or more for extra power. More power helps you cut metal faster and more easily.

How Can Variable Speed Motors Enhance The Performance Of A Metal Lathe In Terms Of Power Consumption And Machining Efficiency?Variable speed motors help metal lathes work better by allowing you to change the speed easily. When you adjust the speed, the machine uses just the right amount of power. This means less energy is wasted, which saves on electricity. It also helps you cut metal more smoothly and quickly, making your work more efficient. So, using these motors means you can do your job faster and save money on power!

What Are The Potential Consequences Of Using A Motor That Is Underpowered For A Specific Metal Lathe Operation?If you use a motor that doesn’t have enough power for your metal lathe, bad things can happen. The lathe might not spin fast enough, which makes cutting metal difficult. You could also damage the machine or the part you’re working on. Sometimes, the motor might overheat and break. This can make your work take longer and cost more to fix.