Have you ever wondered what makes a metal lathe work smoothly? A big part of that answer lies in understanding lathe power requirements. When you operate a lathe, the right power feed can make all the difference in your projects.

Imagine trying to carve a intricate design into metal. If your lathe doesn’t have the right power, it could stall or become hard to control. This not only frustrates you but can also ruin your work.

Did you know that choosing the correct motor size and power feed can be like picking the right tool for a job? Just like using a sharp knife makes slicing easier, the right power ensures your lathe runs well.

In this article, we will explore the vital factors influencing lathe power requirements. We’ll also dive into how understanding metal lathe power feed can enhance your skills. Are you ready to learn the secrets to smooth and efficient metalworking?

Lathe Power Requirements: Understanding Metal Lathe Power Feed

Lathe Power Requirements for Metal Lathe Power Feed

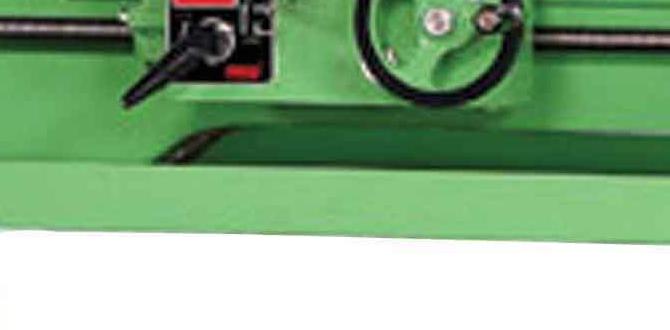

Choosing the right power for your metal lathe is crucial. Power feed helps create smooth, even cuts. But how do you know what you need? First, think about the size of your lathe. Larger lathes need more power to run effectively. Did you know that a small lathe may only need 1 HP, while big ones require 3 HP or more? Understanding your lathe’s power requirements ensures better performance. Wouldn’t you want to make your projects easier and more enjoyable?Understanding Lathe Power Requirements

Definition of power requirements in metal lathes. Importance of selecting the right power for lathe operations.Power requirements for metal lathes refer to the energy needed to operate these machines effectively. Choosing the right power is crucial because it ensures the lathe can handle the job without breaking a sweat—or worse, breaking down! A strong lathe can make smoother cuts, saving time and effort. Think of it as picking the best shoes for a race; you want the right fit to run fast. Remember, if your lathe is underpowered, you might end up just spinning your wheels!

| Lathe Operation | Power Requirement |

|---|---|

| Light cutting | 1-2 HP |

| Medium cutting | 3-5 HP |

| Heavy cutting | 7-10 HP |

Calculating Power Needs for Different Metalworking Tasks

Factors influencing power requirements based on specific tasks. Examples of power calculations for turning, drilling, and milling operations.Power needs depend on what you’re doing. For example, turning requires less power than drilling or milling. Each task eats up energy differently. When you turn, the lathe spins the metal nice and smooth. Drilling uses more force to push through. Milling? Well, that’s a whole workout! Here’s a simple table showing how power needs change:

| Task | Power Requirement (HP) |

|---|---|

| Turning | 1-2 HP |

| Drilling | 2-5 HP |

| Milling | 3-7 HP |

Remember, the right power helps your machine work smarter, not harder. Think of it like a superhero; the more power it has, the more impressive the feats it can perform!

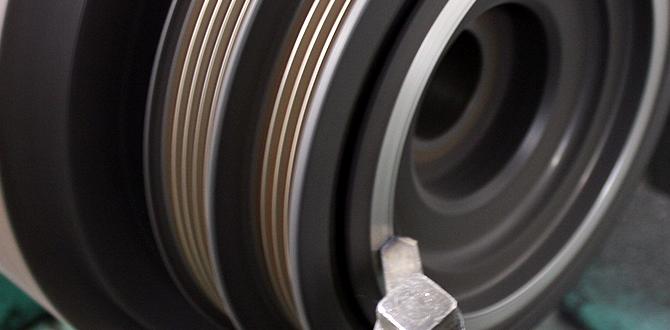

Types of Motors Used in Metal Lathes

Comparison of AC vs. DC motors. Advantages and disadvantages of each type for power feed applications.Metal lathes can use two main types of motors: AC and DC. AC motors are like the steady tortoise; they’re reliable but not as quick. They can handle heavy loads but lack speed control. DC motors, on the other hand, are the speedy hares of the lathe world. They offer great speed control and are perfect for power feed jobs. However, they might need more maintenance. So, which one to choose? Here’s a handy comparison:

| Motor Type | Advantages | Disadvantages |

|---|---|---|

| AC Motor | Reliable, can handle heavy loads | Poor speed control |

| DC Motor | Great speed control, efficient | More maintenance needed |

In the end, pick the motor that best fits your needs. Remember, it’s not always about speed; sometimes, slow and steady wins the lathe race!

Understanding Power Feed Mechanisms

Explanation of different power feed mechanisms (automatic vs manual). How power feed improves efficiency and precision in metalworking.Power feed mechanisms help machines move tools during metalworking. There are two main types: automatic and manual. Automatic feeds are quicker and require less effort. Manual feeds give more control but can be tiring. Using power feeds boosts efficiency and precision in cutting. Think about how a robot can do things faster than a human! With a power feed, tools work smoother and create better parts.

What is the advantage of using automatic versus manual power feeds?

Automatic power feeds are faster and easier, while manual feeds offer more control. They each have their own uses, depending on the job. For many tasks, automatic feeds save time and improve quality.

- Automatic power feeds save time.

- Manual power feeds allow for precise adjustments.

- Choosing the right one can boost the project’s success.

Energy Efficiency and Lathe Power Consumption

Tips for optimizing energy consumption during lathe operations. Benefits of energyefficient practices in metalworking.Saving energy while using a lathe is like finding a hidden treasure! Start by keeping your machine in tip-top shape. A well-maintained lathe runs smoother and uses less power. Also, consider using gear ratios wisely; they can greatly reduce energy use. Finally, switch to LED lights in your workspace. They last longer and save electricity, plus they don’t heat up like the sun!

Adopting these smart habits brings big wins. You’ll cut costs, save the environment, and impress your friends. Who wouldn’t want to be known as the energy-saving lathe wizard? Get started today!

| Tip | Benefit |

|---|---|

| Regular Maintenance | Less energy use |

| Smart Gear Selection | Higher efficiency |

| LED Lighting | Low power consumption |

Common Power Issues and Solutions

Identification of frequent powerrelated problems in metal lathes. Troubleshooting tips and maintenance practices for optimal performance.Metal lathes can sometimes throw tantrums, especially with power issues. Common problems include weak feeds, sudden stops, and weird noises like a cat caught in a blender. To tackle these, check connections and ensure the power supply is steady. Regular maintenance, like cleaning and lubrication, keeps lathes happy and running smoothly. Don’t forget to check the motor; a tired motor is like a sleepy puppy—no fun at all!

| Problem | Solution |

|---|---|

| Weak power feed | Check connections and power supply. |

| Sudden stops | Inspect motor and wiring. |

| Strange noises | Lubricate and clean the machine. |

Future Trends in Lathe Power Technologies

Innovations in motor and drive technology for lathes. The impact of automation and smart systems on power requirements and efficiency.The future of lathe power technologies looks bright! New motors and drive systems are more efficient. They use less energy and work faster than before. Smart systems and automation help machines adjust power needs on their own. This saves time and materials. These advancements make lathes more reliable and easier to use. You’ll be amazed at how technology can reshape our work!

How are motors changing in lathe technology?

Innovations in motors make lathe operations smoother and faster. High-performance motors can now handle heavier loads while using less energy. This leads to better performance.

Key Benefits of Modern Motor Technology:

- Higher efficiency

- Improved control

- Less maintenance required

What role does automation play?

Automation boosts efficiency in lathe operations. Smart systems help machines adapt to different tasks. This means less downtime and more productivity.

Conclusion

In conclusion, understanding lathe power requirements helps you choose the right metal lathe. A power feed can make your work easier and more efficient. Remember to check motor size and power settings before starting. By knowing these key points, you can enhance your metalworking skills. Explore more resources to learn and practice these techniques for better projects!FAQs

What Factors Influence The Power Requirements Of A Metal Lathe When Using A Power Feed System?The power needs of a metal lathe with a power feed system depend on a few things. First, the size of the metal you are working with matters. Bigger pieces of metal need more power. Second, how fast you want to cut also affects power. If you go faster, you’ll need more energy. Lastly, the type of feed system can change the power needed to do the work.

How Do Different Materials Affect The Power Consumption Of A Metal Lathe During Machining Operations?Different materials use different amounts of power when you work with a metal lathe. Soft materials, like aluminum, need less energy because they are easier to cut. Hard materials, like steel, take more power since they resist cutting. This means you will use more electricity when machining harder materials. Choosing the right material can help save energy and make your work easier.

What Is The Significance Of Torque In Calculating The Power Requirements For A Lathe’S Power Feed?Torque is important because it helps us understand how much force the lathe needs to turn. When you feed material into the lathe, it needs enough power to cut through it. The more torque there is, the easier it is for the lathe to do its job. So, by knowing torque, we can make sure the lathe has enough power to work well. Without enough torque, cutting will be slow or even stop.

How Can I Determine The Appropriate Motor Size For A Metal Lathe With A Power Feed Feature?To find the right motor size for your metal lathe, think about the work you’ll do. Look at the largest and hardest materials you plan to use. Bigger and tougher materials need a stronger motor. Check your lathe’s manual for recommendations too. This will help you pick the best motor size for your needs.

What Are The Common Power Ratings For Metal Lathes With Integrated Power Feed Systems, And How Do They Compare To Manual Lathes?Metal lathes with power feed systems usually have power ratings between 1 to 5 horsepower (HP). This helps them work faster and easier than manual lathes. Manual lathes often have lower power ratings, around 0.5 to 2 HP. So, powered lathes can handle bigger jobs and save us time.